A remote control valve

A technology for remote control of valves and valve bodies, applied to valve details, diaphragm valves, valve devices, etc., can solve the problems of easily dismantled actuators, inconvenient disassembly, and easy deformation of threads, so as to avoid the decline of sealing performance, facilitate installation and Ease of disassembly, installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

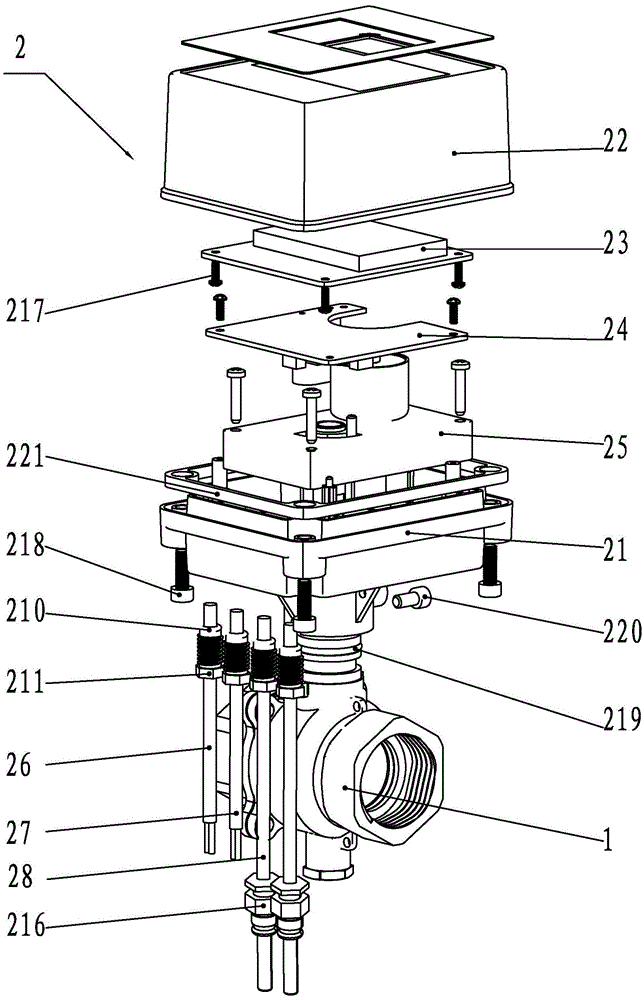

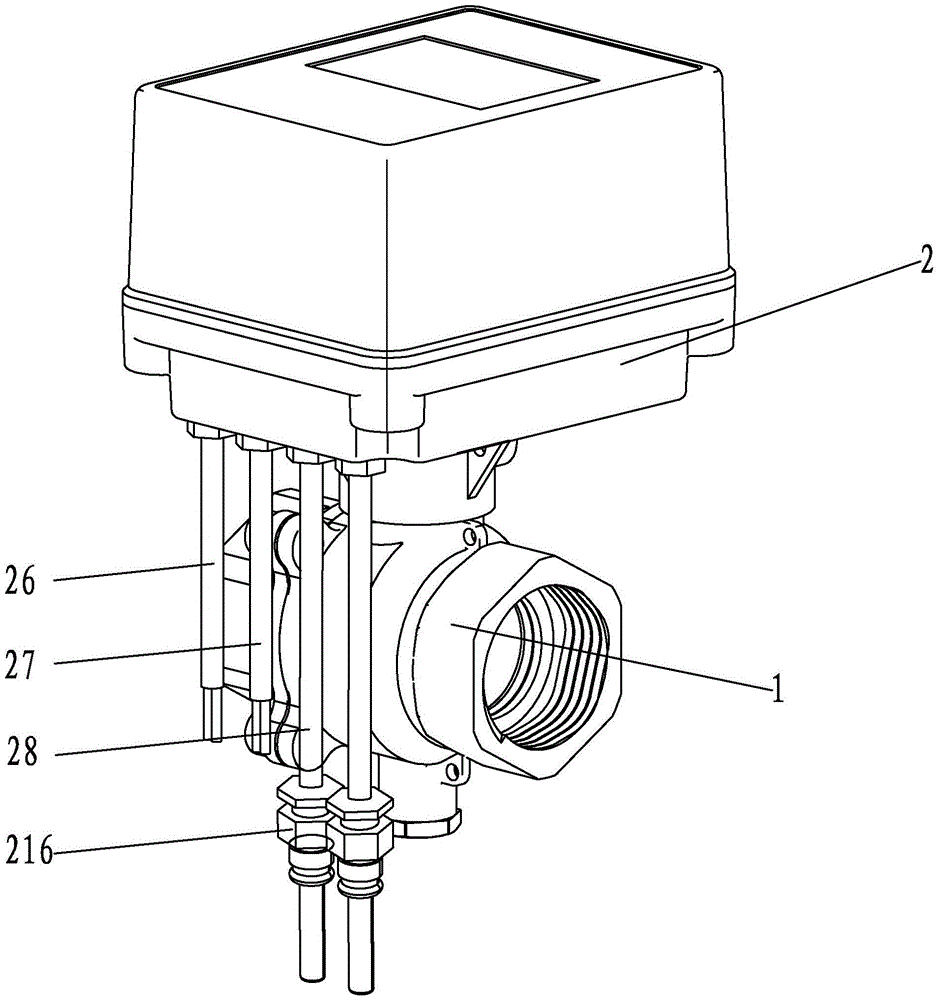

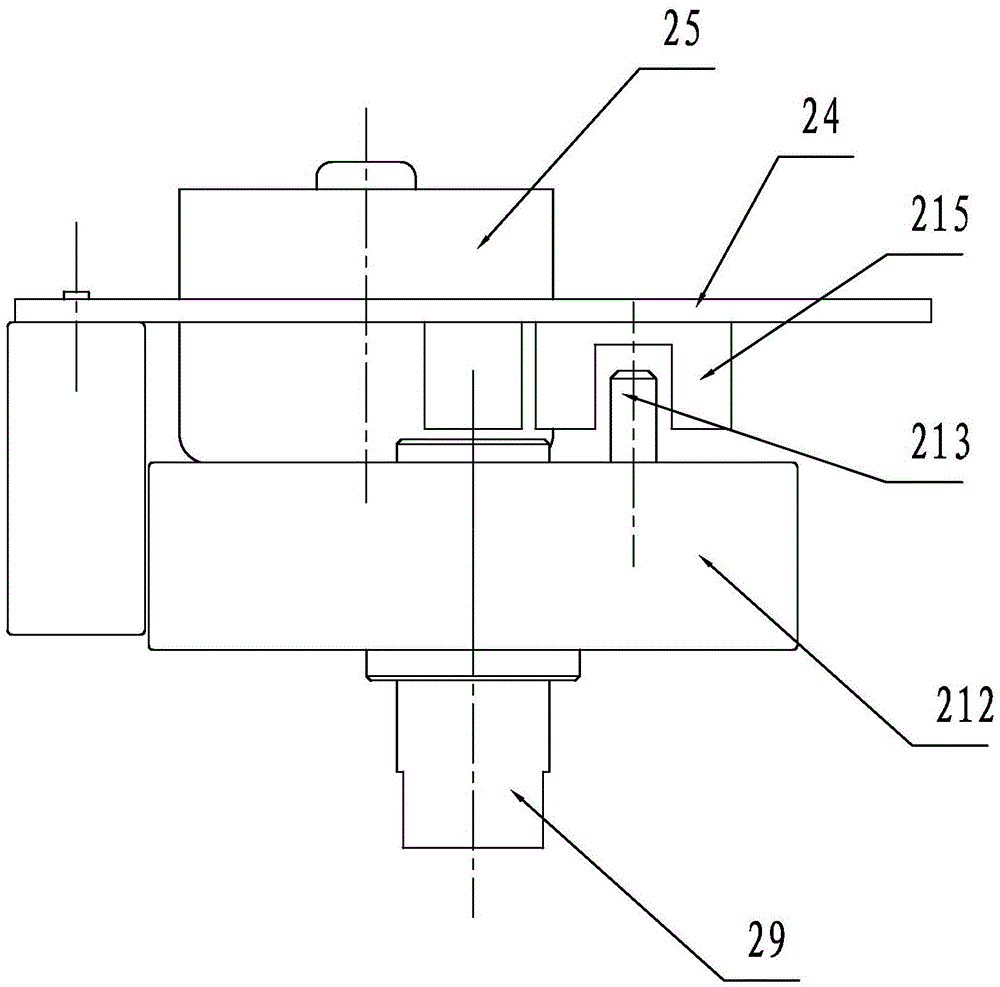

[0031] Such as Figure 1 to Figure 6 As shown, a remote control valve includes a valve body 1 and an actuator 2 installed on the valve body 1. The actuator 2 includes a base 21 and a valve cover 22 that is mounted on the upper end of the base 21. The base 21 and the valve cover 22 Connected by four hexagon socket countersunk head screws 218, a gasket 221 is installed at the connection between the base 21 and the valve cover 22, and a display circuit board 23 and a main circuit board 24 are sequentially installed between the valve cover 22 and the base 21 from top to bottom , deceleration motor 25 and connector 29, the upper part of the valve body 1 extends into the lower part of the base 21, and is detachably connected with the lower part of the base 21 through the hexagon socket head screw 220, and the display circuit board 23 is installed on the valve cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com