Method and control system for drying silkworm cocoons by microwaves and far infrared waves

A far-infrared light, cocoon drying technology, applied in drying, drying solid materials, furnaces and other directions, can solve the problems of unfavorable internal quality of silkworm cocoons, no dust removal facilities, low efficiency, etc., to improve the efficiency and quality of cocoon drying, and improve the overall economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

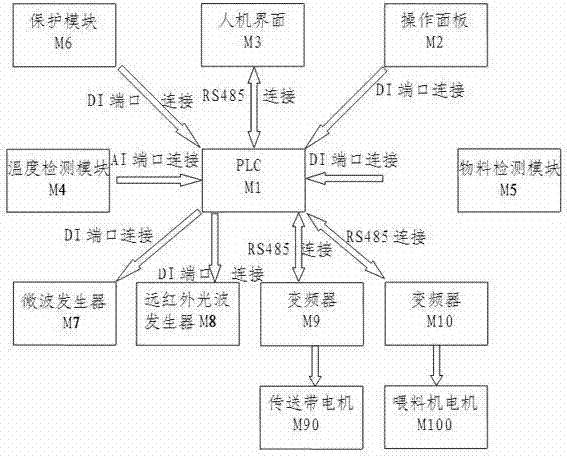

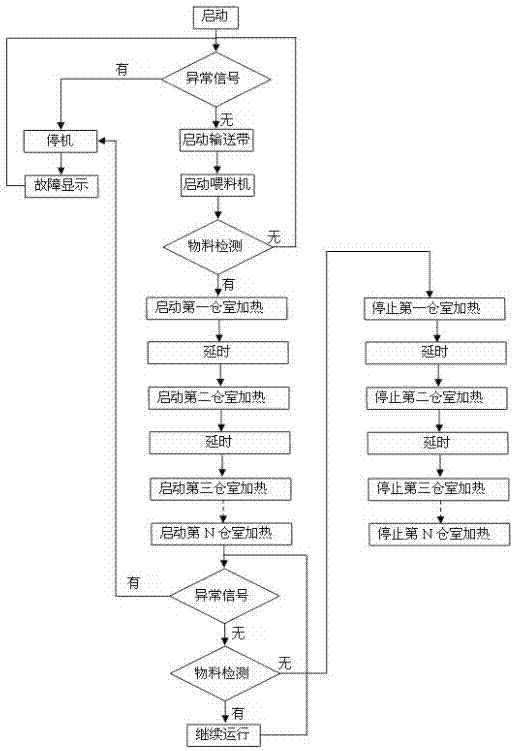

[0029] The method for drying cocoons of silkworm cocoons by using microwaves and far-infrared light waves comprises the steps of:

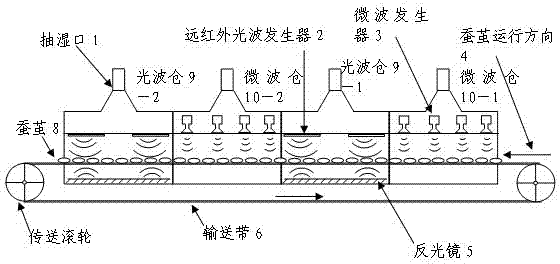

[0030] (a) Far-infrared light wave cocoon drying step: set up a far-infrared light wave cocoon drying chamber, place a far-infrared light wave generator in the far-infrared light wave cocoon drying chamber, and perform far-infrared light wave treatment on silkworm cocoons;

[0031] (b) Microwave cocoon drying step: a microwave cocoon drying chamber is provided, and a microwave generator is placed in the microwave cocoon drying chamber to perform microwave treatment on silkworm cocoons.

[0032] The working sequence of the steps (a) and (b) is: microwave cocoon drying bin-far infrared light wave bin-microwave cocoon drying bin or far infrared light wave bin-microwave cocoon drying bin-far infrared cocoon drying bin Cocoons are baked in combination with light wave warehouses.

[0033] It also includes a cocoon conveying step: setting up a cocoon co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com