Conductivity enhancing liquid for paper substrate of supercapacitor, paper substrate and preparation method

A supercapacitor and conductive enhancement technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of poor electrode conductivity, poor flexibility of metal substrate electrodes, and shedding of active electrode materials. performance, is conducive to rapid film formation, and the effect of fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

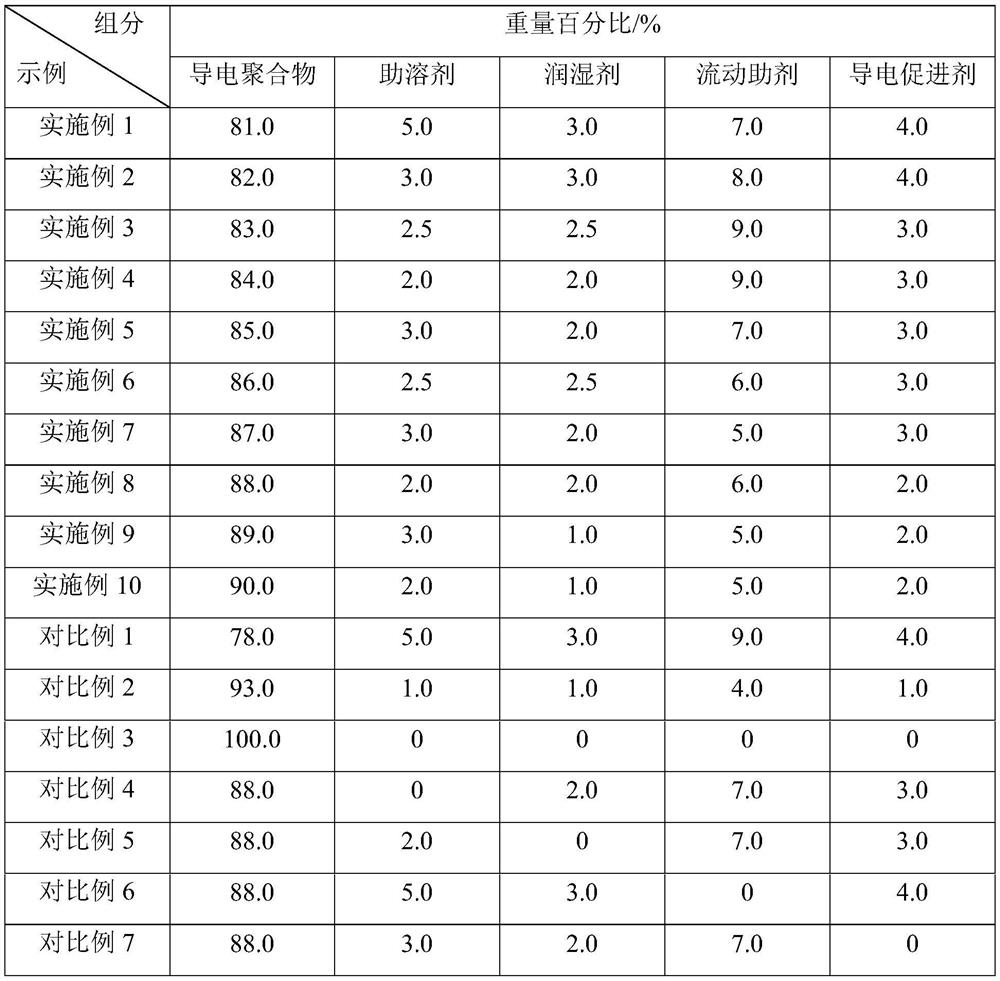

[0051] By weight percentage, take 81% poly-3,4-ethylenedioxythiophene-polystyrenesulfonic acid (PEDOT-PSS) aqueous dispersion liquid as conductive polymer, take 5% ethanol as cosolvent, take 3% Polyethylene glycol-400 was used as a wetting agent, 7% of mannitol was used as a flow aid, and 4% of dimethyl sulfate was used as a conductive promoter. Add each component into the stirring container, adjust the stirring frequency to 50Hz, the rotating speed is 650rpm, stir for 15 minutes, then adjust the stirring frequency to 40Hz, rotating speed 3500rpm, continue stirring for 15 minutes to obtain a mixed solution, and then mix the mixed solution at a frequency of 40KHz Ultrasonic vibration was performed for 1.5 hours to obtain a conductivity-enhancing solution, and the viscosity of the conductivity-enhancing solution was detected to be 14.5 mPa·s.

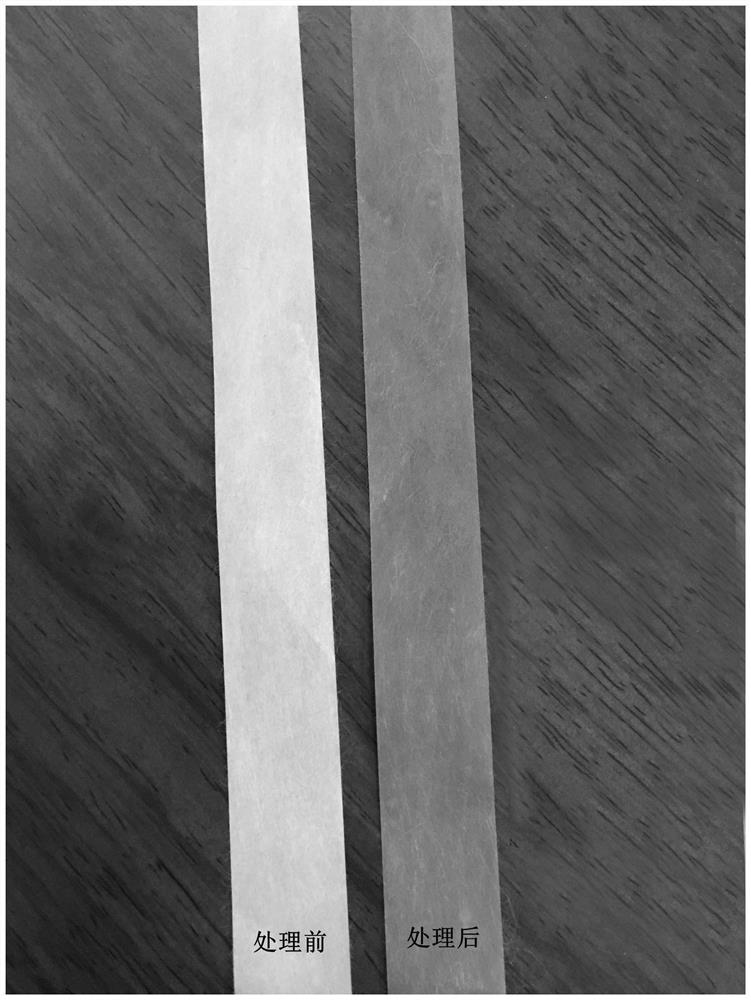

[0052] Add the conductive enhancing liquid to the liquid storage tank of the vertical spraying machine, and use the rolling roller to re...

Embodiment 2

[0054] The difference from Example 1 is that the proportioning ratio by weight of the conductive enhancing liquid is: 82% poly 3,4-ethylenedioxythiophene-polystyrene sulfonic acid (PEDOT-PSS) aqueous dispersion liquid is used as the conductive polymer, which is taken as 3% ethylene glycol is used as a cosolvent, 3% polyethylene glycol-600 is used as a wetting agent, 8% sorbitol is used as a flow aid, and 4% ethylene carbonate is used as a conductive promoter. The viscosity of the conductivity enhancing liquid is 22.5 mPa·s. When spraying, the discharge speed is 0.7m / min, and the drying temperature is 115°C.

Embodiment 3

[0056] The difference from Example 1 is that the proportioning ratio by weight of the conductive enhancing liquid is: 83% poly-3,4-ethylenedioxythiophene-polystyrenesulfonic acid (PEDOT-PSS) aqueous dispersion as the conductive polymer, which is taken as 2.5% isopropanol as co-solvent, 2.5% polyethylene glycol-600 as wetting agent, 9% sorbitol as flow aid, 3% vinyl sulfite as conduction promoter, The viscosity of the conductivity enhancing liquid is 22.2 mPa·s. When spraying, the discharge speed is 0.9m / min, and the drying temperature is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com