Thin plate cut tobacco drying equipment with cross-flow section

A thin plate drying and flowing technology, applied in the field of tobacco production and processing, can solve the problems of low production capacity, low dehydration rate, low filling value, etc., and achieve the effects of improving filling value, improving cleanliness, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

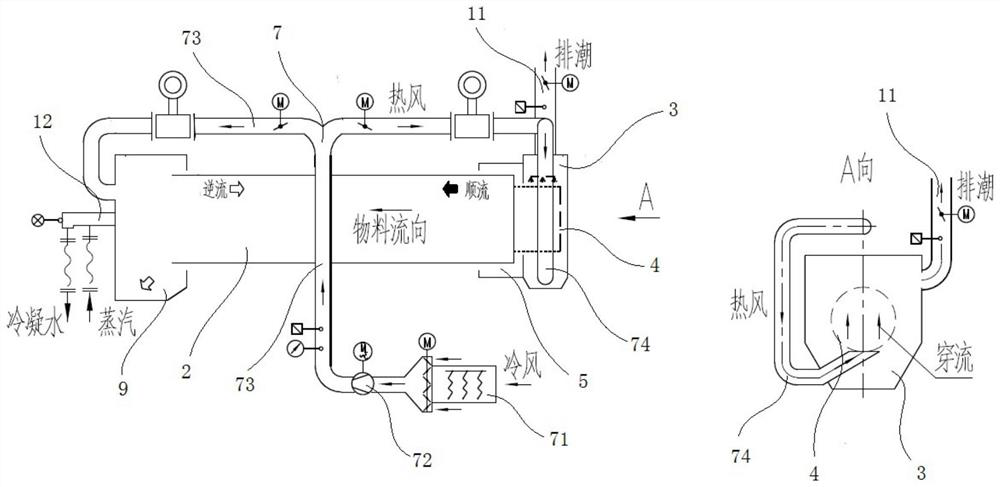

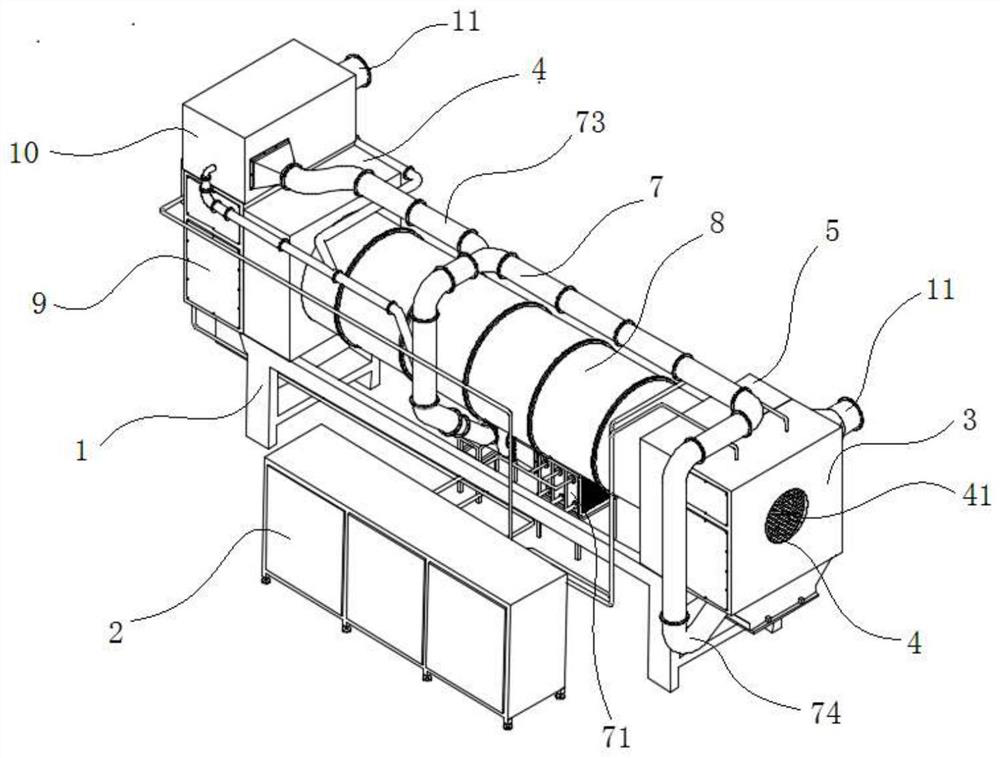

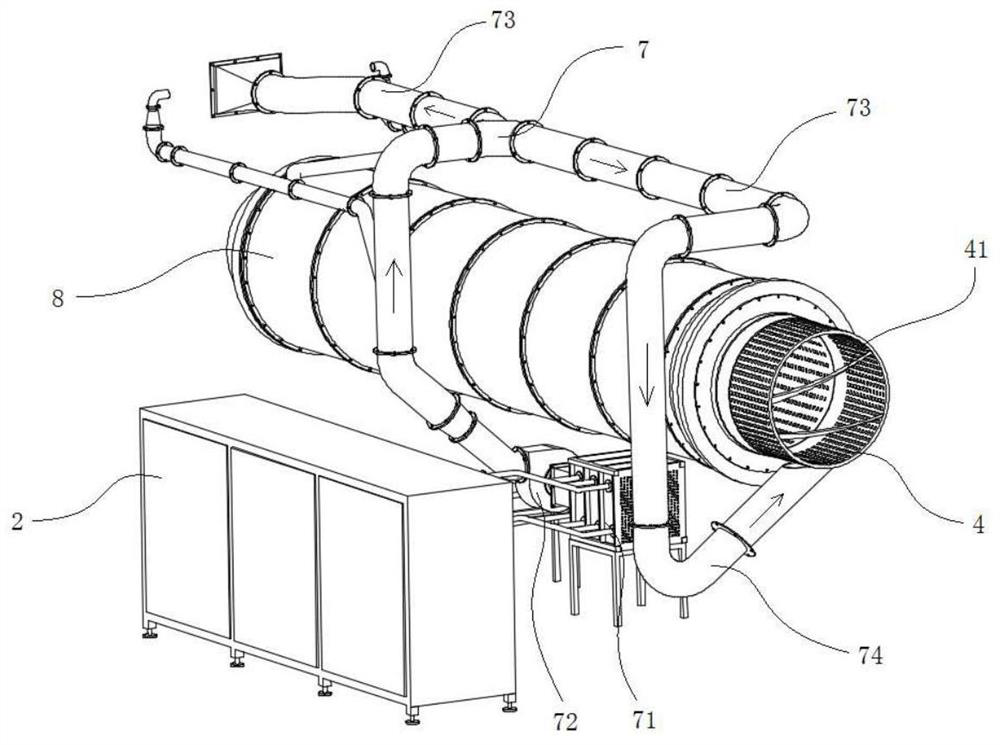

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, specific implementations thereof will be described in detail below in conjunction with the accompanying drawings.

[0028] As shown in the drawings of the description, a thin-plate silk drying equipment with a flow-through section includes a frame assembly 1, a silk drying device arranged on the frame assembly 1, and a pipeline arranged on one side of the frame assembly 1 Control cabinet 2, the signal connection control device of the silk drying device. The silk drying device is mainly composed of the front chamber 3, the material guide cylinder 4, the wind cover 5, the silk drying cylinder rotation mechanism 6, the hot air system 7, the silk drying cylinder 8, the rear Chamber 9, steam dust extraction box 10 and moisture exhaust air duct 11, wherein, the front chamber 3 is set at the front end of the silk drying cylinder 8 and the wind hood 5; the rear cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com