A drying device based on glass fiber cloth processing application

A glass fiber cloth and drying device technology, applied in textile processing machine accessories, textile material processing, textile material processing equipment configuration, etc., can solve the problem that the carbon fiber cloth cannot be heated evenly, the drying effect is not good, and the waste heat cannot be fully utilized and other problems to achieve the effect of avoiding vibration and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

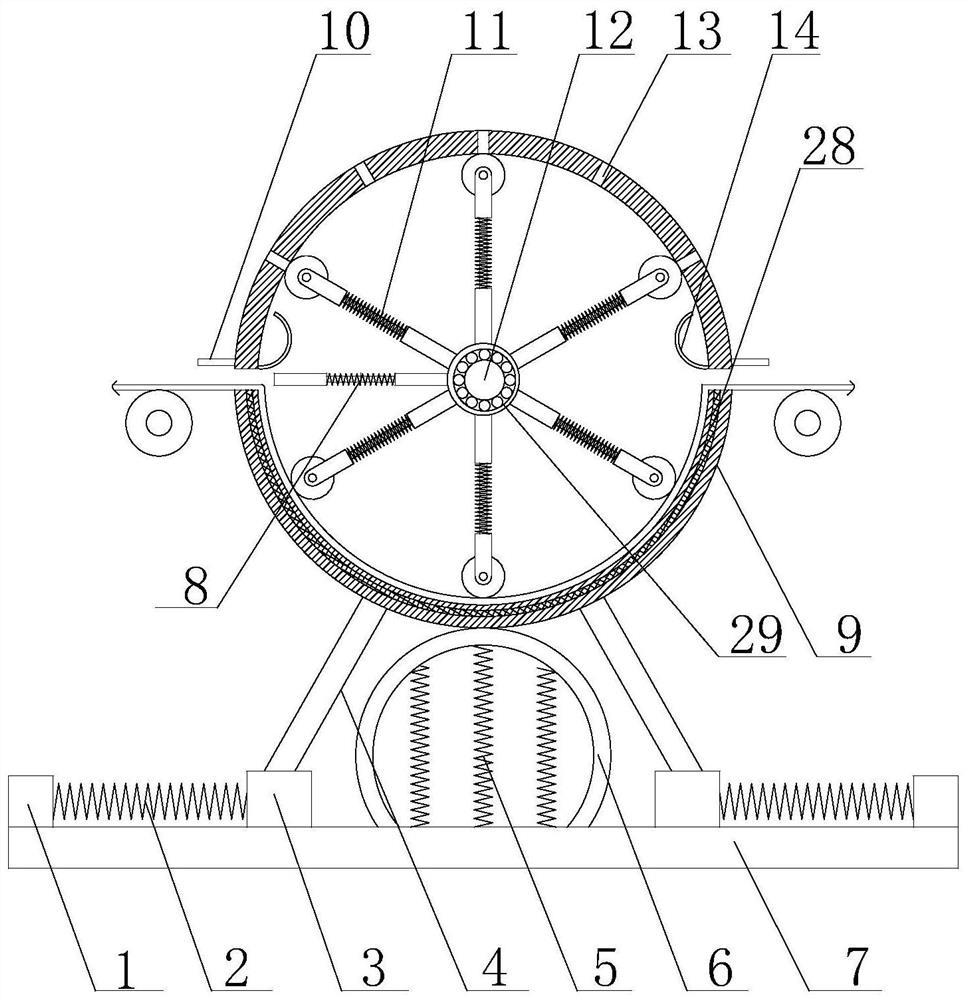

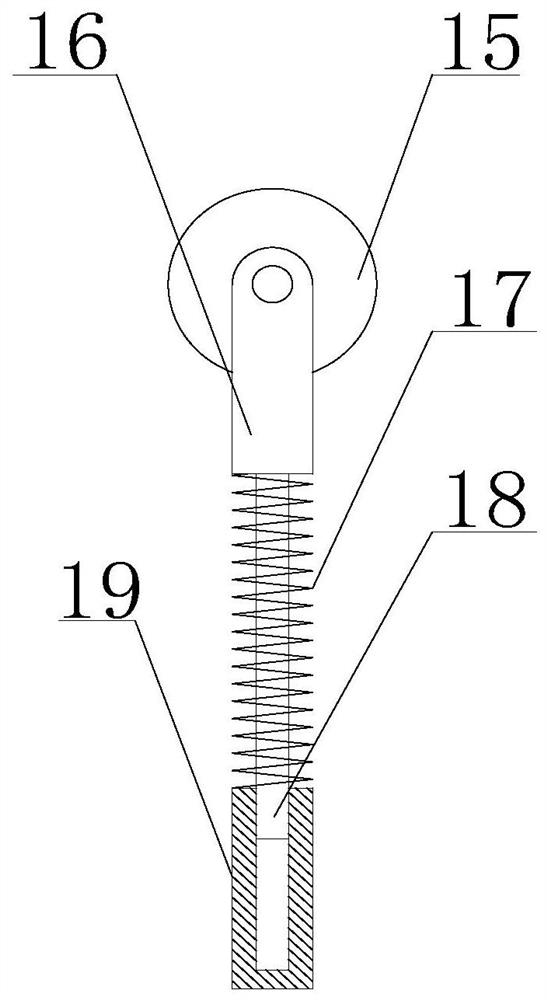

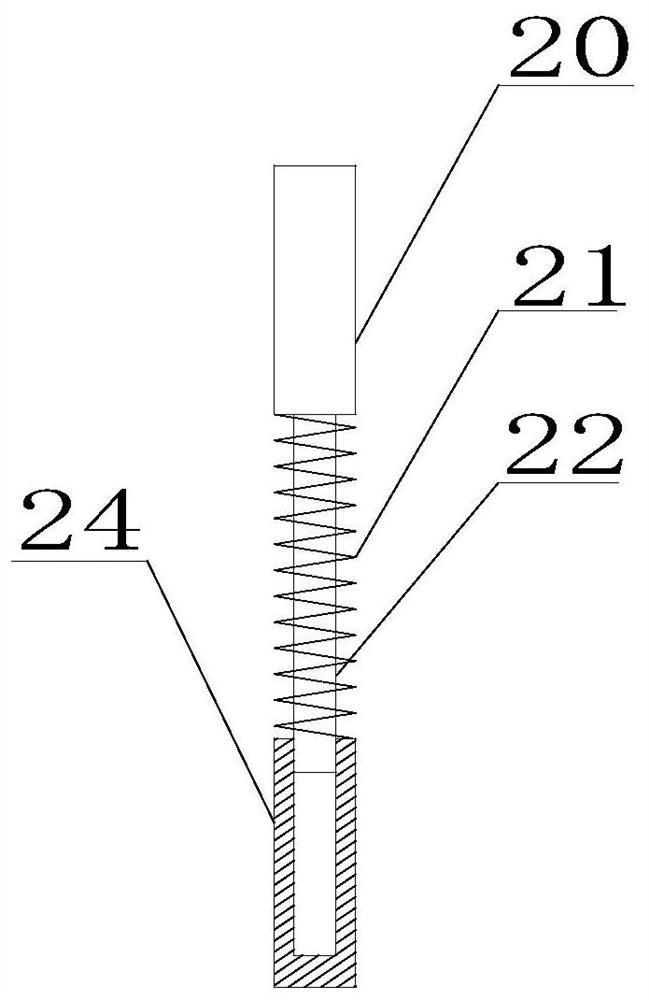

[0037] like Figure 1 to Figure 5 As shown, a drying device based on glass fiber cloth processing application of the present invention includes a base 7, a drying cylinder 9 is arranged above the base 7, and a drying cylinder 9 is provided between the drying cylinder 9 and the base 7. The two ends of the drying cylinder 9 are closed structures, and both sides of the circumferential outer wall of the drying cylinder 9 are provided with cloth inlets, and the two cloth inlets are located in the horizontal direction. There is also a heating wire 28 in the inner wall of the drying cylinder 9, and a fixing rod 12 is arranged in the drying cylinder 9. The fixing rods 12 are distributed along the axial direction of the drying cylinder 9, and the fixing rod 12 is provided with the fixing rod 12. The matching bearing 29, a plurality of telescopic rods 11 are arranged on the outer circumferential wall of the bearing 29, the telescopic rods 11 are distributed in a circular array around th...

Embodiment 2

[0039] On the basis of Embodiment 1, the damping assembly includes an arc-shaped curved plate 6 and a plurality of second damping members 5, the curved plate 6 has elasticity, and the two ends of the curved plate 6 are respectively connected to the top of the base 7, One end of the second shock absorbing member 5 is connected to the top of the base 7 , and the other end is connected to the curved surface of the curved plate 6 .

Embodiment 3

[0041] On the basis of Embodiment 2, the shock absorber assembly further includes two bumps 1 , two sliders 3 , two first shock absorbers 2 , two diagonal struts 4 , and two of the sliders 3 Located on both sides of the curved plate 6 and close to the end of the base 7 , the sliders 3 are respectively located between the curved plate 6 and the bump 1 , and one end of the first shock absorbing member 2 is connected to the bump 1 , the other end is connected with the sliding block 3 , one end of the diagonal strut 4 is hinged with the drying cylinder 9 , and the other end is hinged with the sliding block 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com