A Fiber Bragg Grating Displacement Sensor Capable of Multipoint Measurement

A displacement sensor, fiber grating technology, applied in the sensor field, can solve the problems of large error, inconvenient downhole observation, slow response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

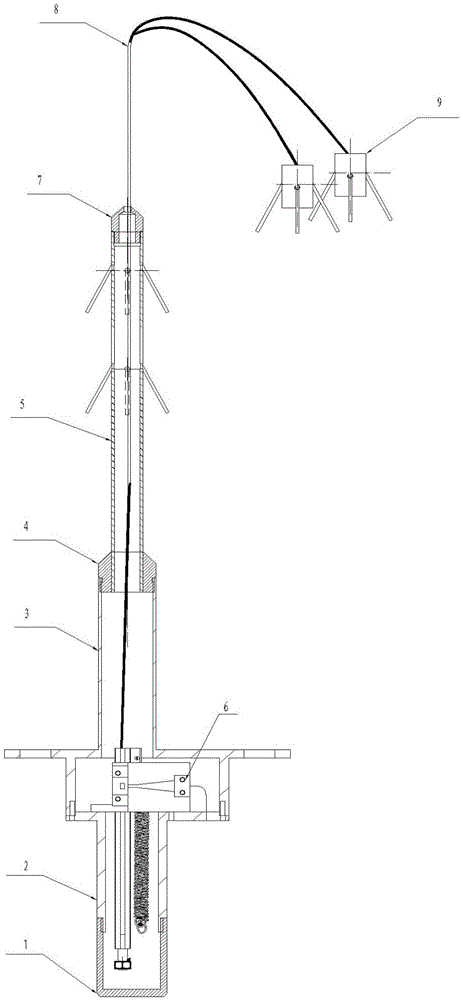

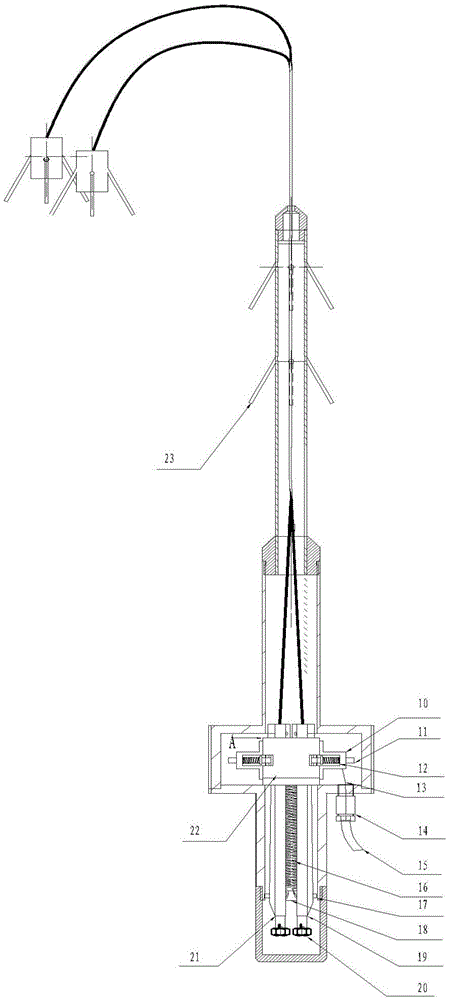

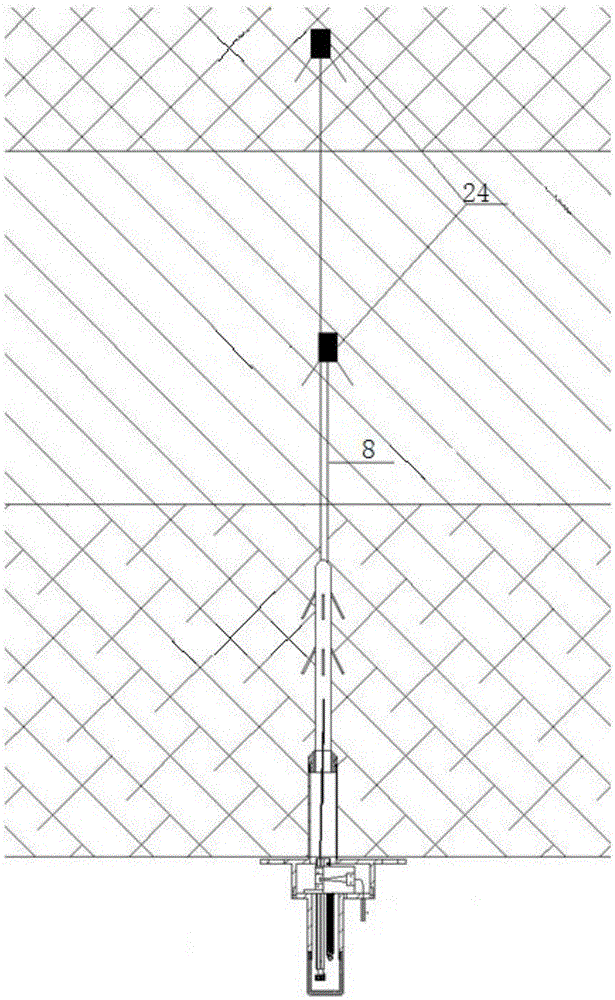

[0064] The present invention is described in detail below in conjunction with accompanying drawing:

[0065] Such as Figure 1-8 As shown, a fiber grating displacement sensor capable of multi-point measurement includes a sensor housing and a fluke structure. Two symmetrically arranged brackets 10 are arranged inside the sensor housing, and compression guide posts are provided on the outside of the brackets 10. 11. The inside of the bracket 10 is provided with a compression spring 12, and the bracket 10 is also provided with a precision guide rail 22 and a precision slide rail. The precision slide rail includes a precision slide rail A19 and a precision slide rail B21. The precision guide rail 22 and the precision slide rail There is a clearance fit between the precision slide rails, and a spring pull rod 17 is arranged under the support 10, and a tension spring 16 is fixed on the upper part of the precision slide rail and the spring pull rod 17, and the tension spring 16 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com