An online motor braking torque detector and its detection method

A motor braking and detector technology, applied in force/torque/work measuring instruments, electric components, instruments, etc., can solve the problems of unsuitable detection of braking torque, poor force bearing, and high precision requirements, to ensure online continuation Safe operation, accurate test results, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

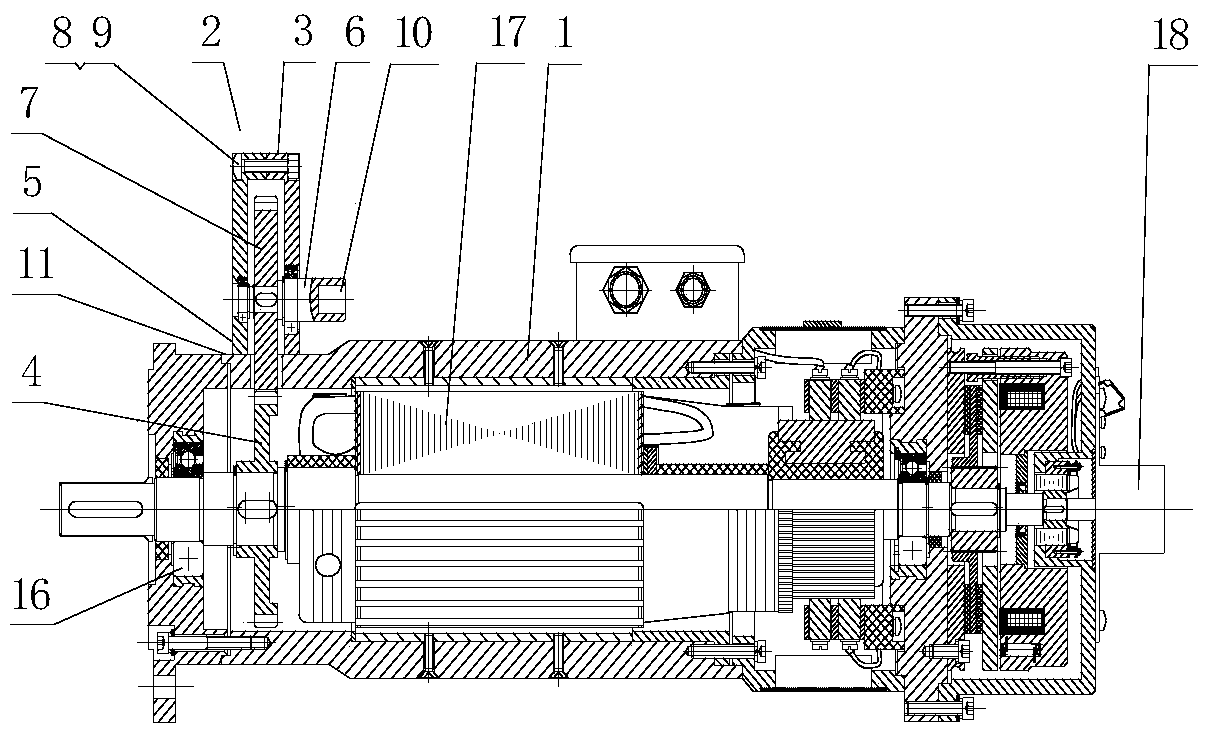

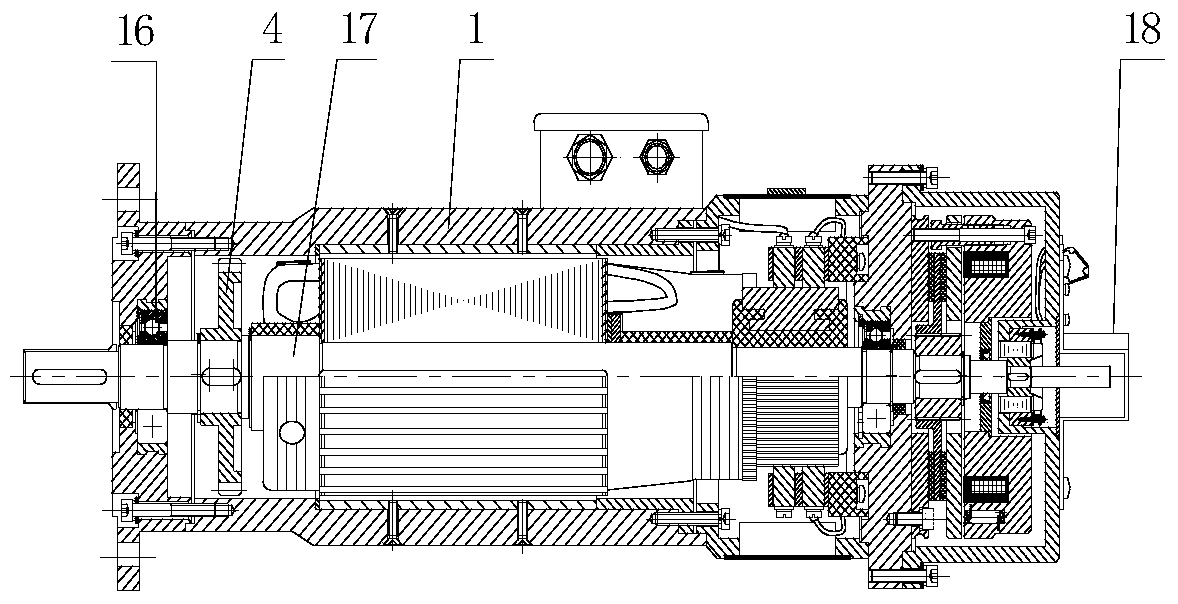

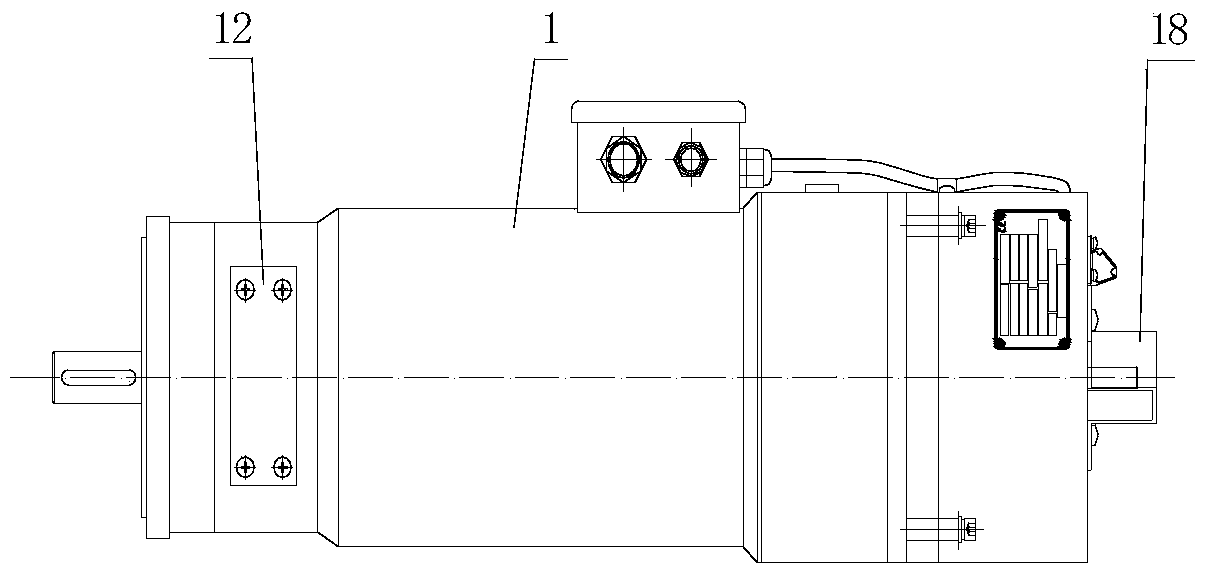

[0058] As shown in the accompanying drawings, the work and principle of the present invention: an online motor braking torque detector and its detection method, which uses the wind-driven motor running on-line as the type selection machine, and is connected to the force-transmitting device by adding Components and installation window, when testing, connect the force measuring device and its force transmission unit to the installation window, make the force transmission gear mesh with the transmission gear and fix the force measurement device with screws, and finally use a commercially available torque wrench to insert the force measurement The power transmission shaft end of the device is pulled, and the torque wrench is pulled to implement online detection of the braking torque of the wind power motor.

[0059] In conjunction with the accompanying drawings, an online motor braking torque detector is fixedly connected with a motor provided with a force transmission element and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com