Patents

Literature

30results about How to "Rigorous testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

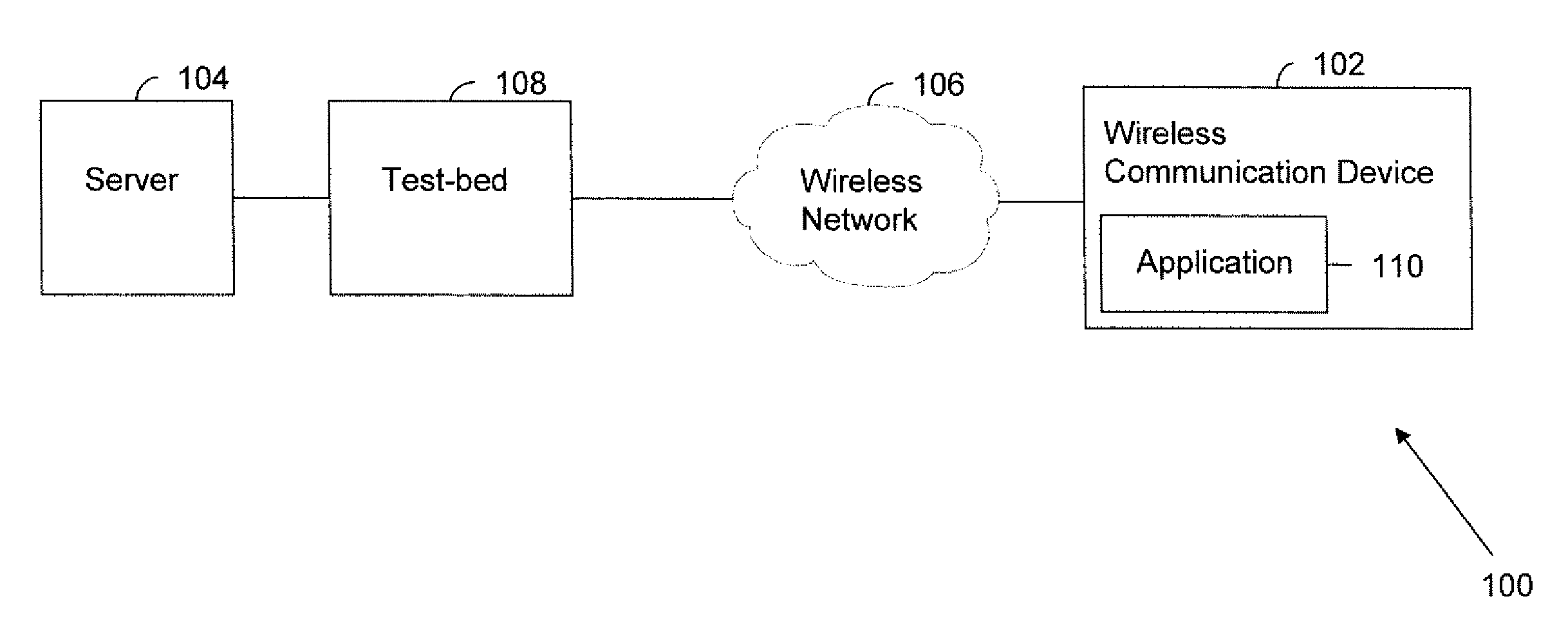

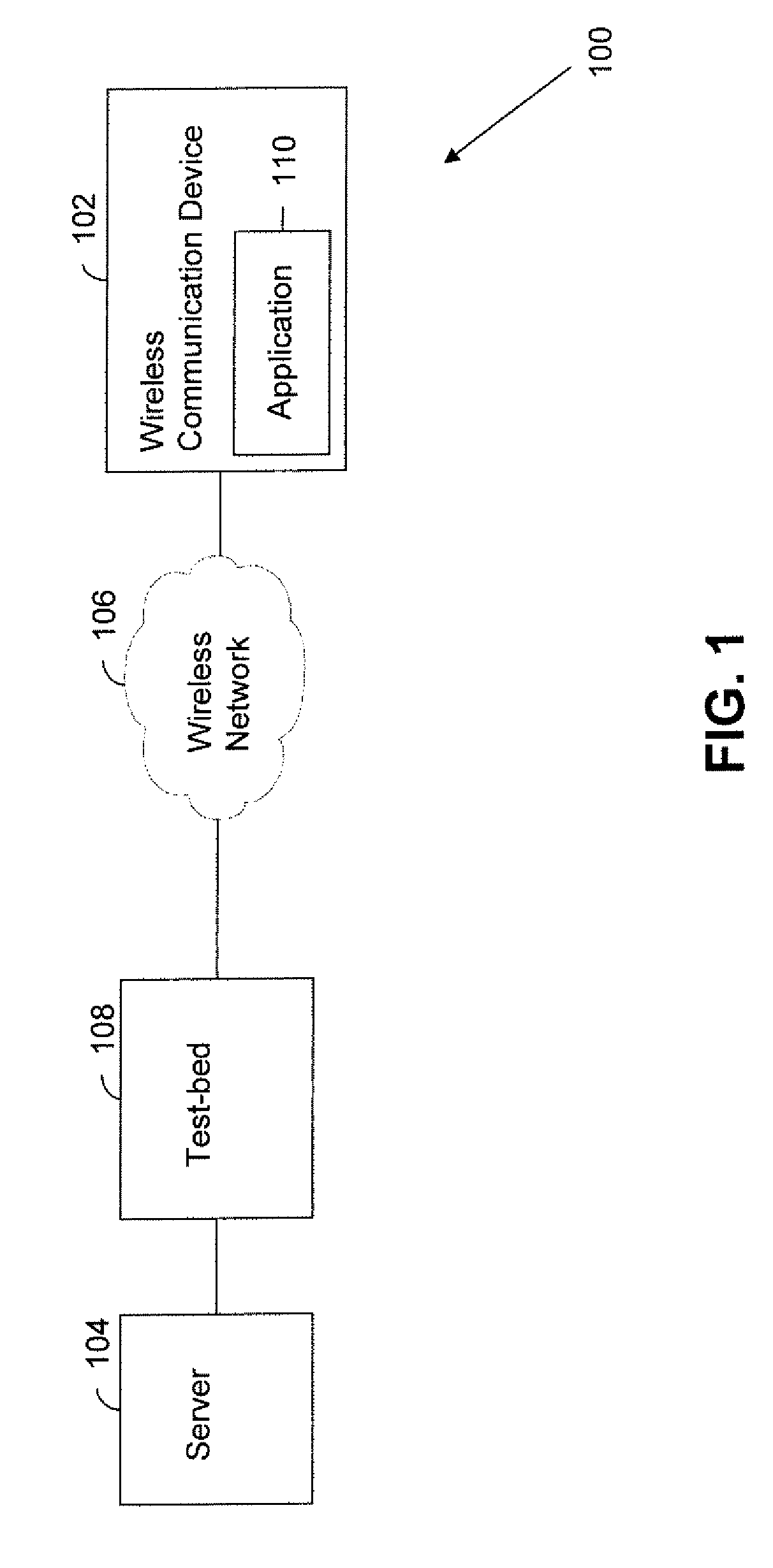

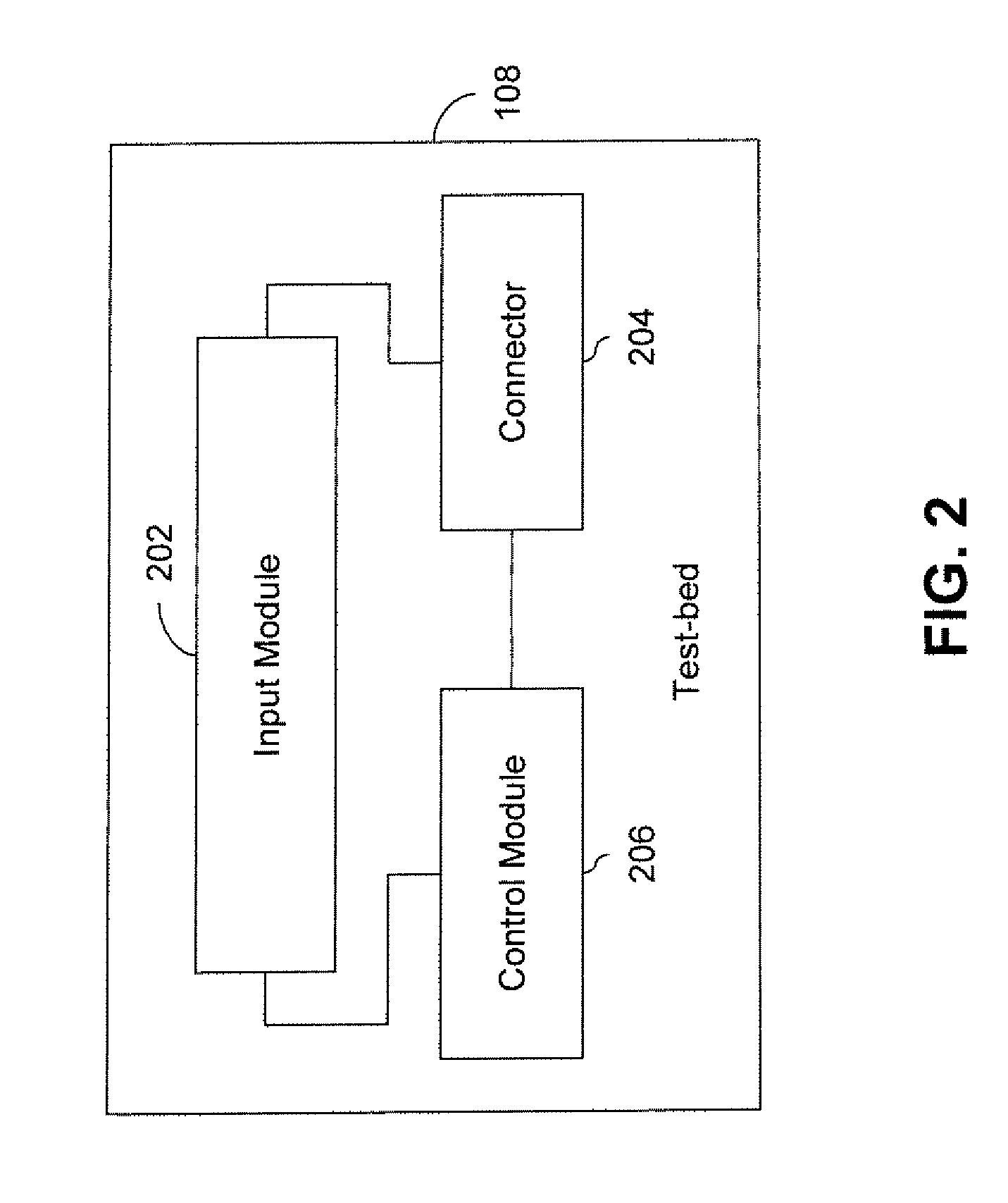

System and method for testing an application installed on a wireless communication device

ActiveUS8028188B2Easy to testRule out the possibilityError detection/correctionData switching networksNetwork conditionsWireless connectivity

The invention describes a test bed, a method and a computer program product for testing an application installed on a wireless communication device. The wireless communication device communicates with a server over a network through the test bed. Further, the test bed is connected to the server and receives various testing parameters from a user. Furthermore, the test bed establishes a wireless connection between the test bed and the wireless communication device. Thereafter, the test bed emulates various network conditions, based on the testing parameters, and subsequently communicates the emulated network conditions to the wireless communication device. The application installed on the wireless communication device experiences the emulated network conditions. The user then tests the application in the emulated network conditions.

Owner:INFOSYS LTD

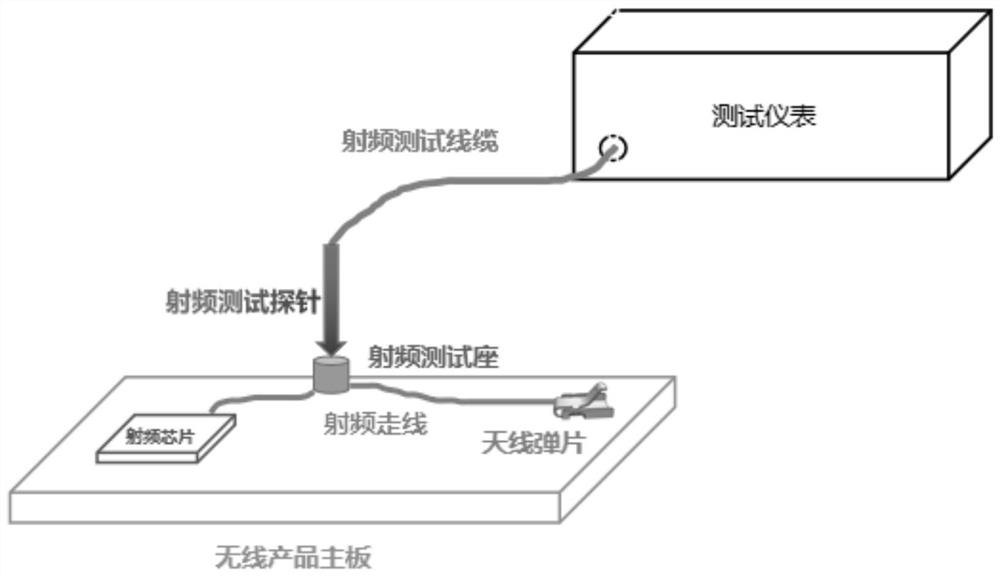

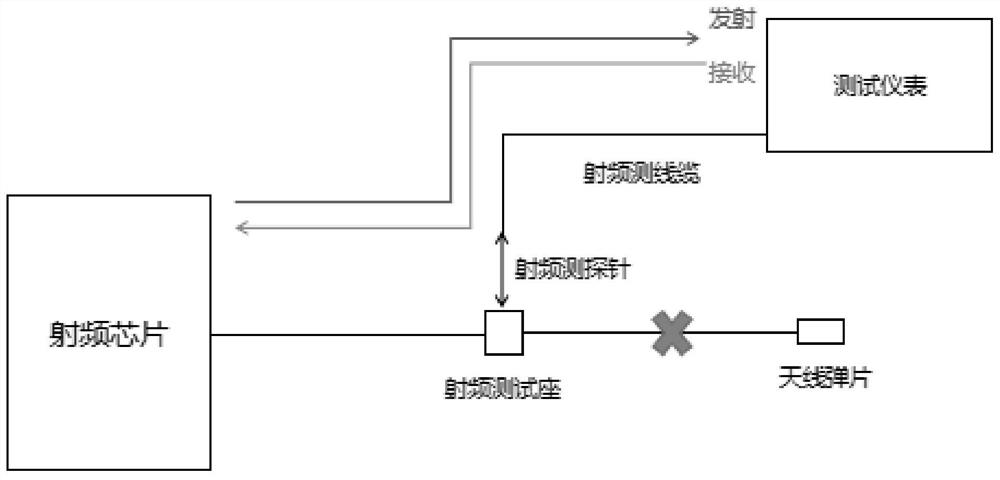

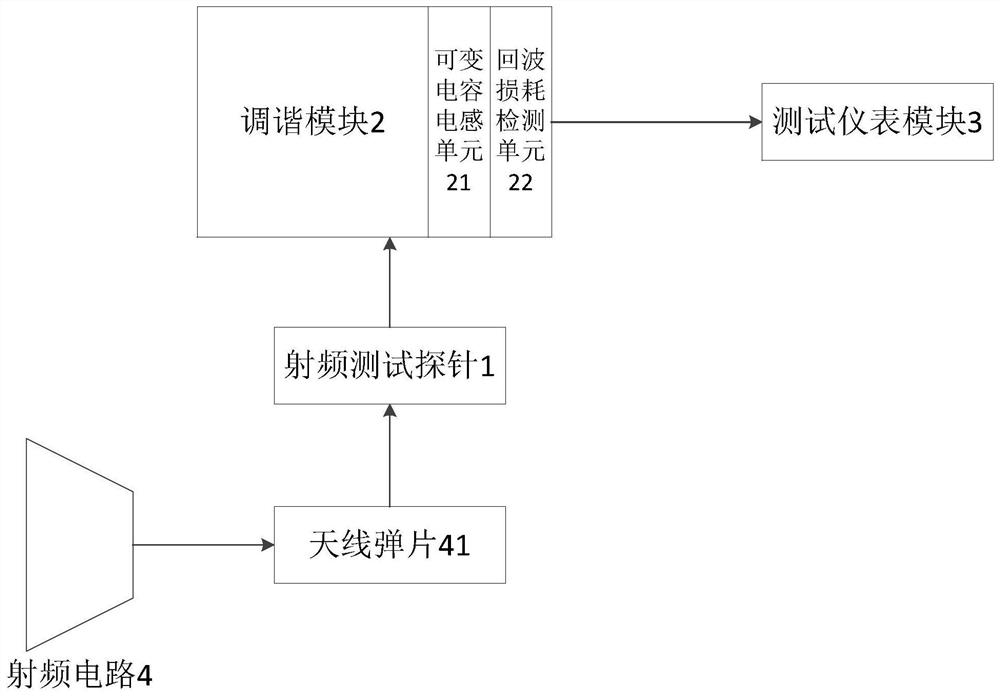

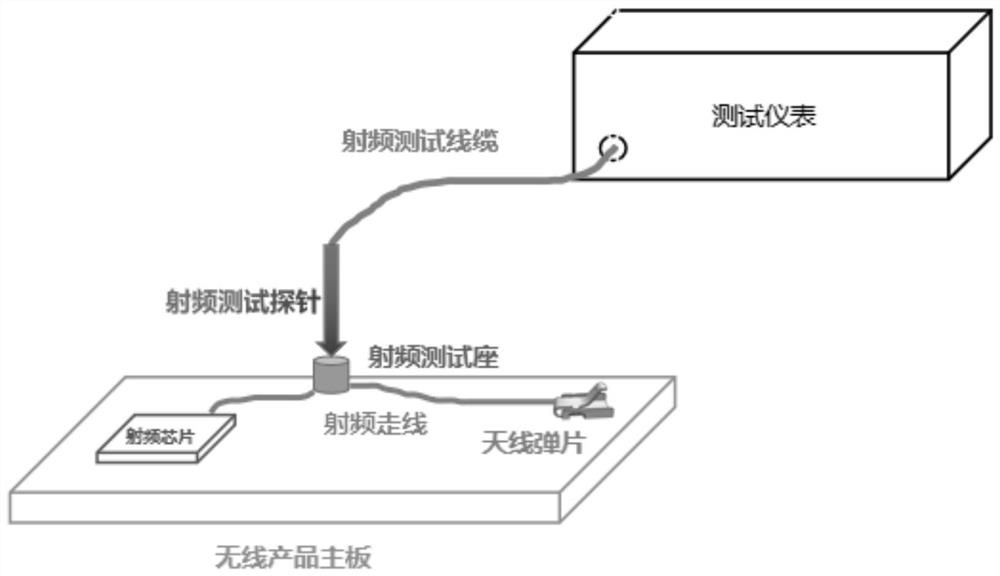

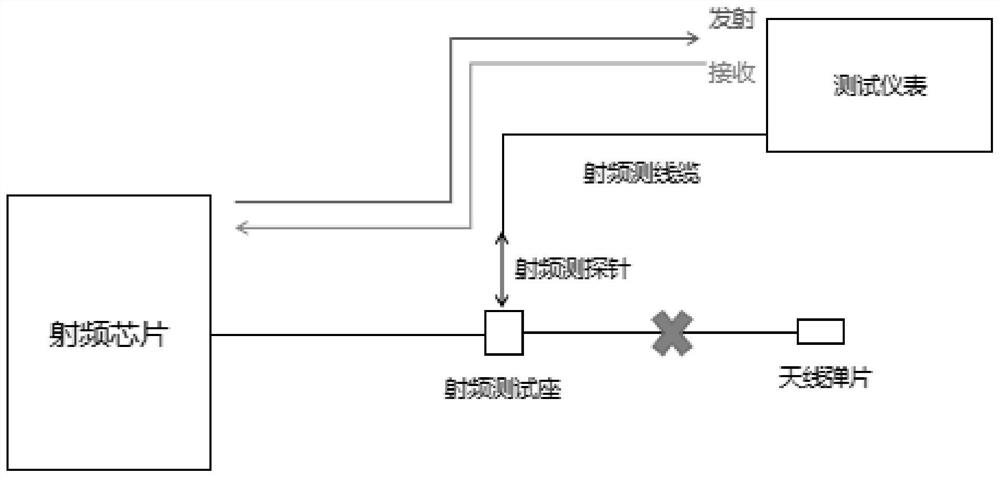

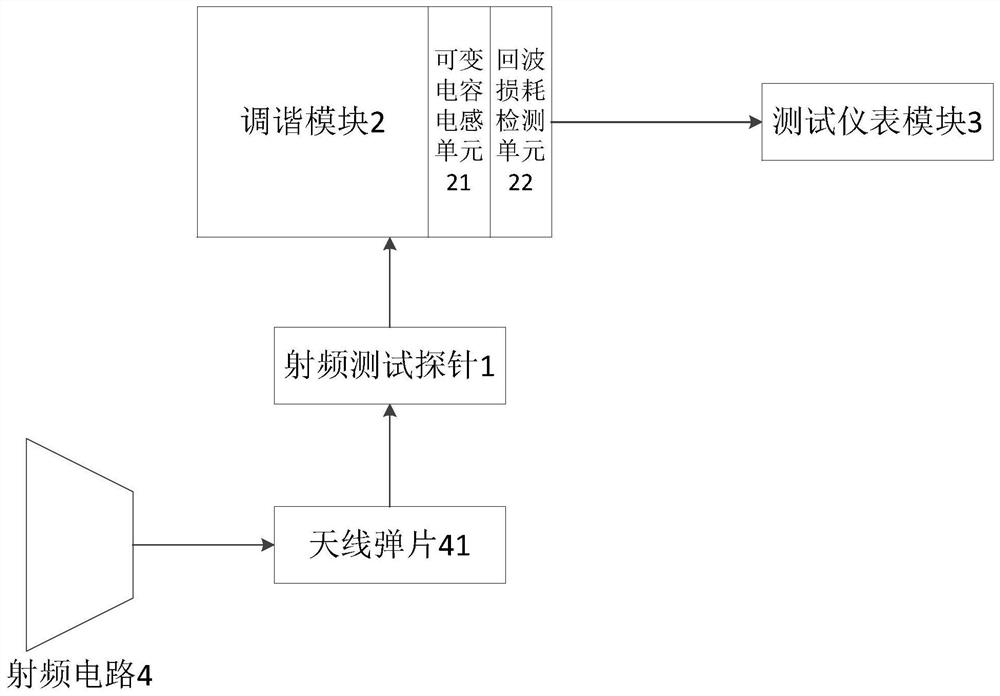

Board-level radio frequency signal testing system, method and device without radio frequency testing base

ActiveCN112003657AOmit designSave costTransmitters monitoringReceivers monitoringElectrical connectionRadio frequency signal

The invention provides a board-level radio frequency signal testing system, method and device without a radio frequency testing base, which are used for testing radio frequency signals of a radio frequency circuit. The board-level radio frequency signal testing system device comprises a radio frequency test probe, a tuning module and a test instrument module, one end of the radio frequency test probe is connected with an antenna elastic sheet of a radio frequency circuit, and the other end is connected with the tuning module; the tuning module is connected with the test instrument module; thetuning module adjusts the matching impedance according to the return loss; the matching impedance is matched with the impedance of the radio frequency circuit; the radio frequency test probe is directly and electrically connected with the antenna elastic sheet in the radio frequency circuit; then, the tuning module is used for adjusting the matching impedance, and whether the matching impedance ismatched in place or not can be judged according to the return loss until the matching impedance is matched with the impedance in the radio frequency circuit, so that the purpose of directly testing aradio frequency signal through the antenna elastic sheet is achieved; the test result is rigorous and the structure is ingenious; and the design space and the production cost of a radio frequency test base in a radio frequency circuit are saved.

Owner:深圳合一测试科技有限公司

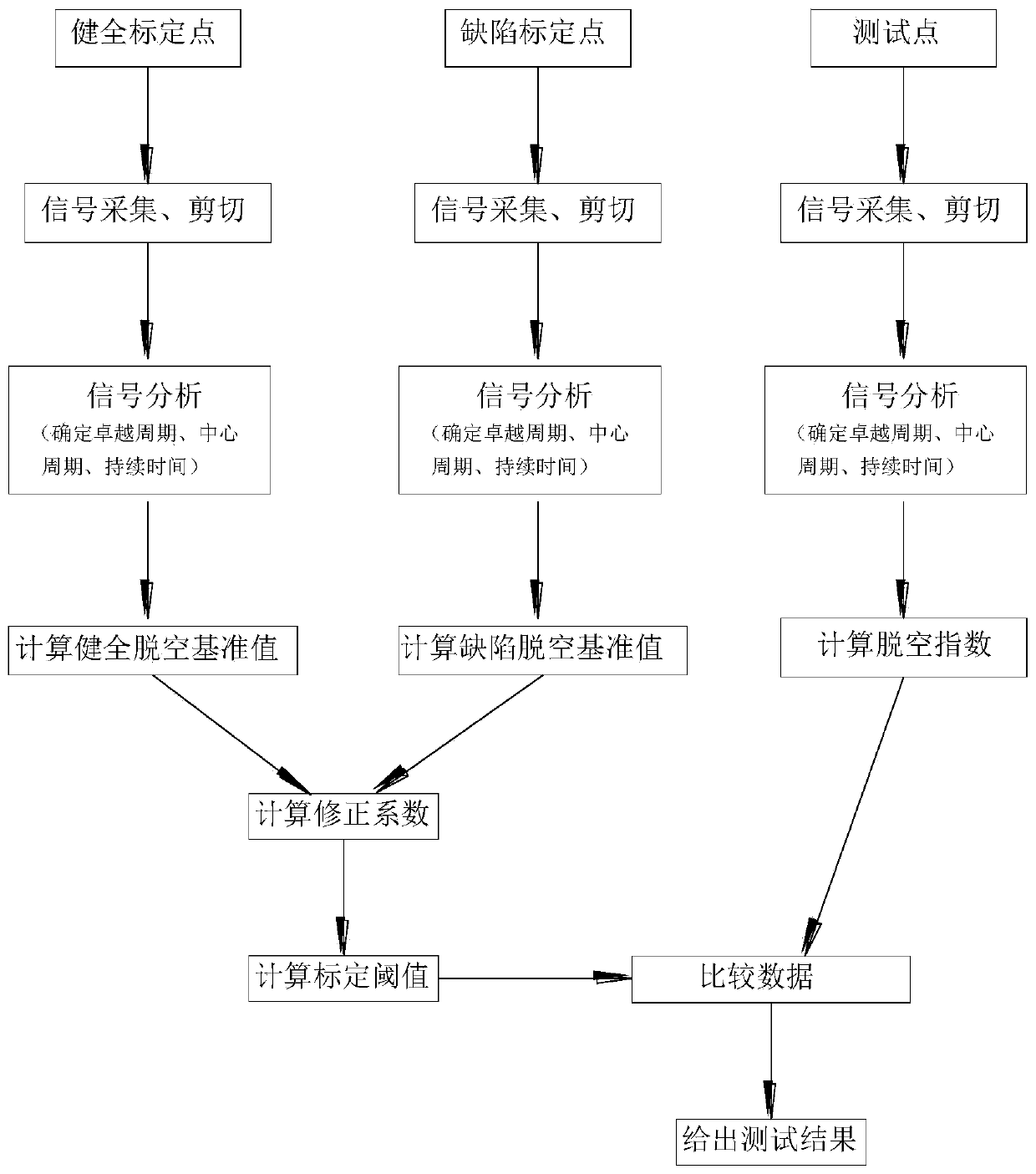

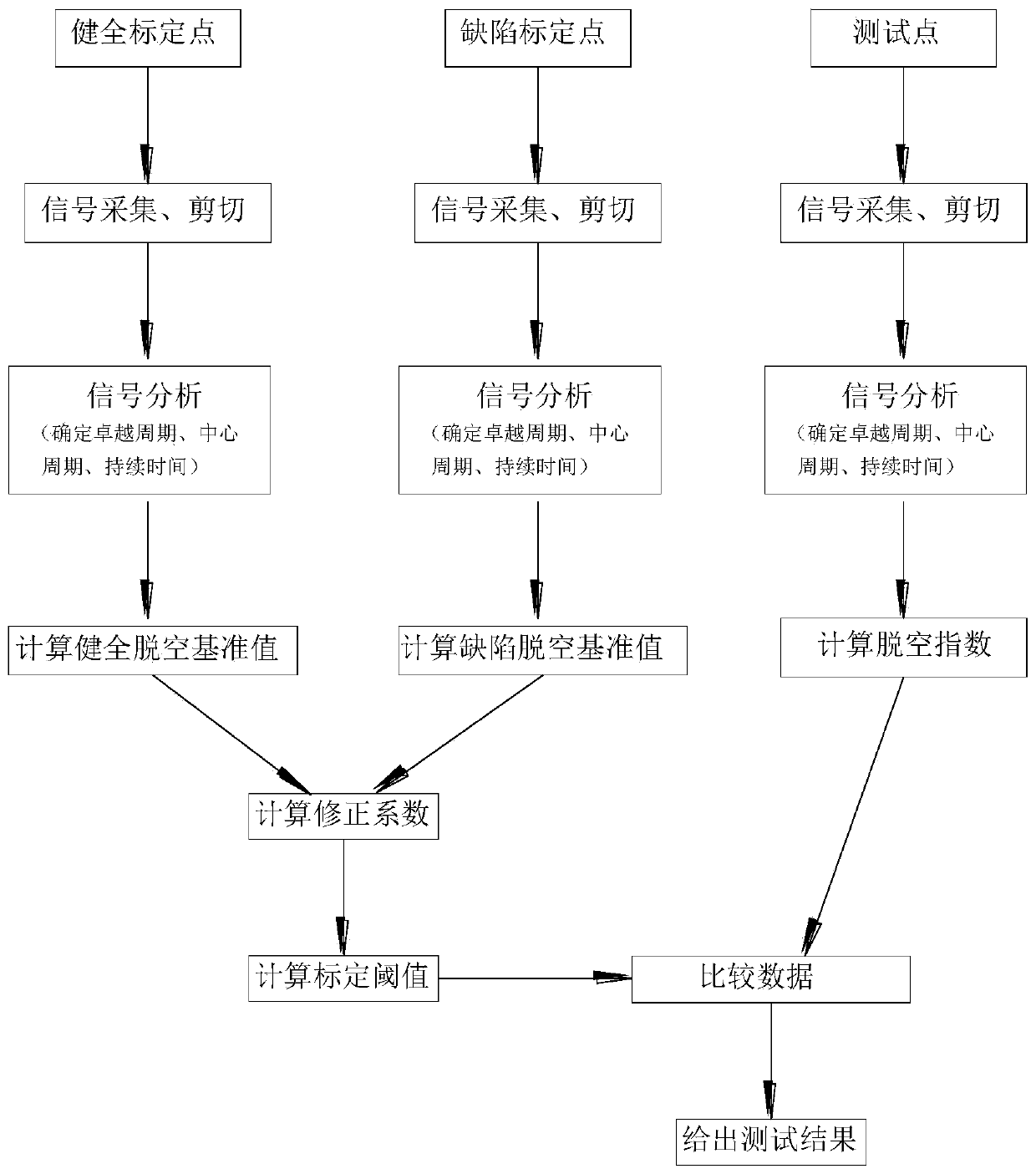

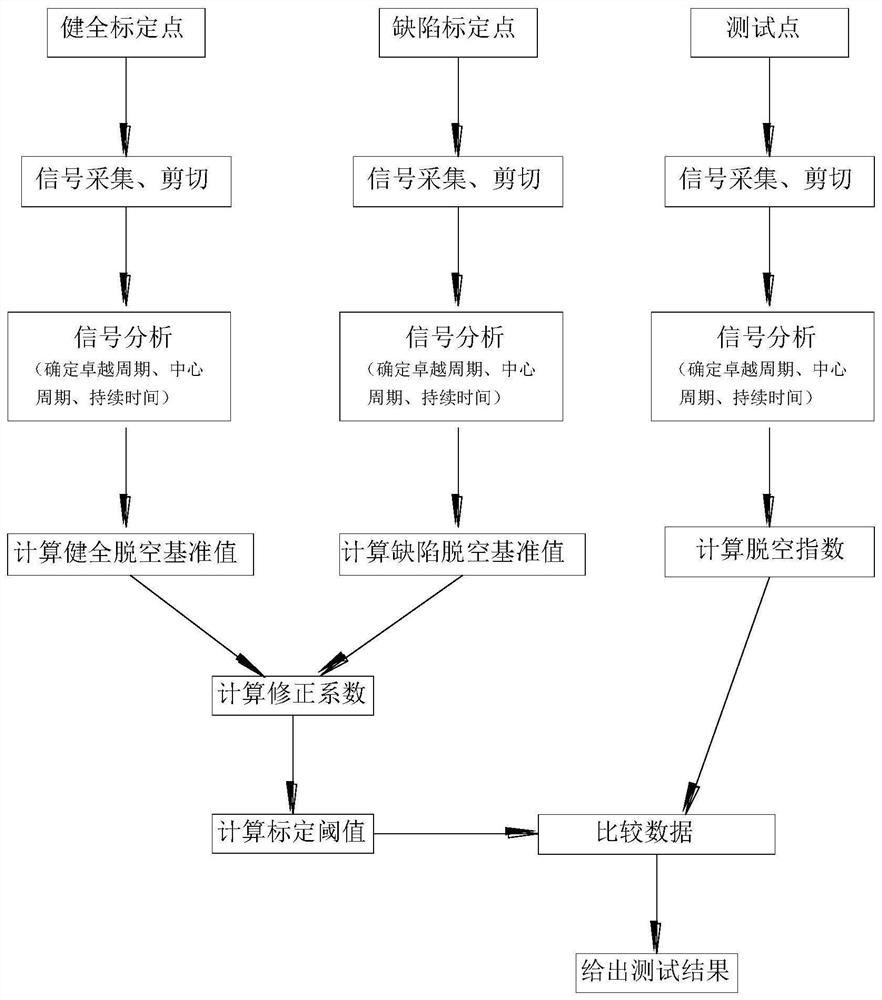

Tunnel lining non-destructive testing method based on audio frequency analysis

ActiveCN110045016AThe test results are accurateDetection scienceAnalysing solids using sonic/ultrasonic/infrasonic wavesTime–frequency analysisNondestructive testing

The invention relates to the technical field of road engineering quality detection, in particular to a tunnel lining non-destructive testing method based on audio frequency analysis, which aims to provide an efficient and accurate non-destructive testing method for tunnel linings. The technical solution adopted is as follows: the following steps are included: acquiring a tunnel lining tapping audio signal at a given sampling frequency by using a mobile terminal with a recording function; trimming the tapping audio signal to retain an effective signal; calculating a calibration threshold according to the effective signal parameters; calculating a test point void index according to the effective signal parameters; comparing the void index with the calibration threshold; and determining the tunnel lining quality according to the comparison result. The invention can carry out non-destructive testing on the surface defects of the lining, and has the characteristics of convenience, high efficiency and accuracy.

Owner:四川升拓检测技术股份有限公司

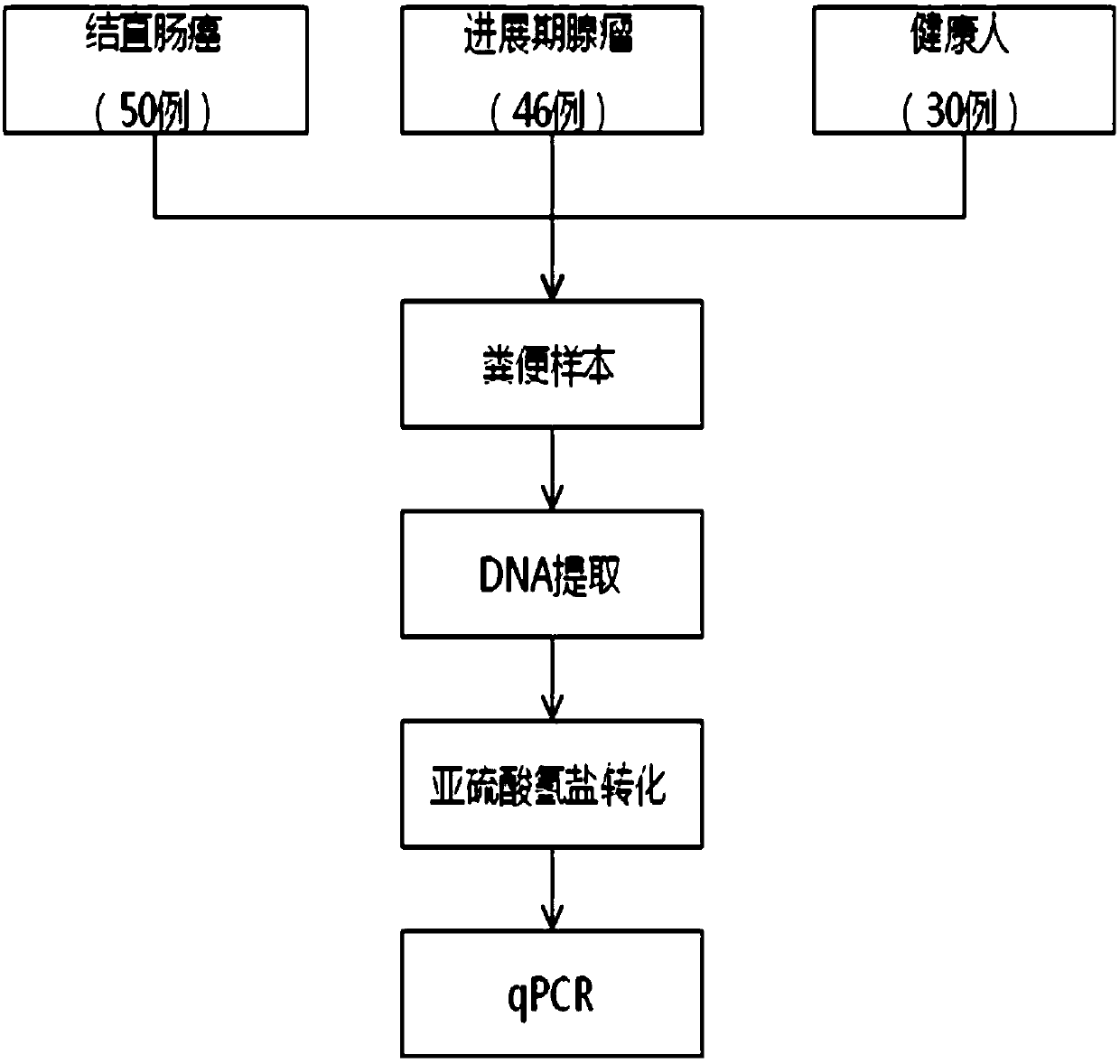

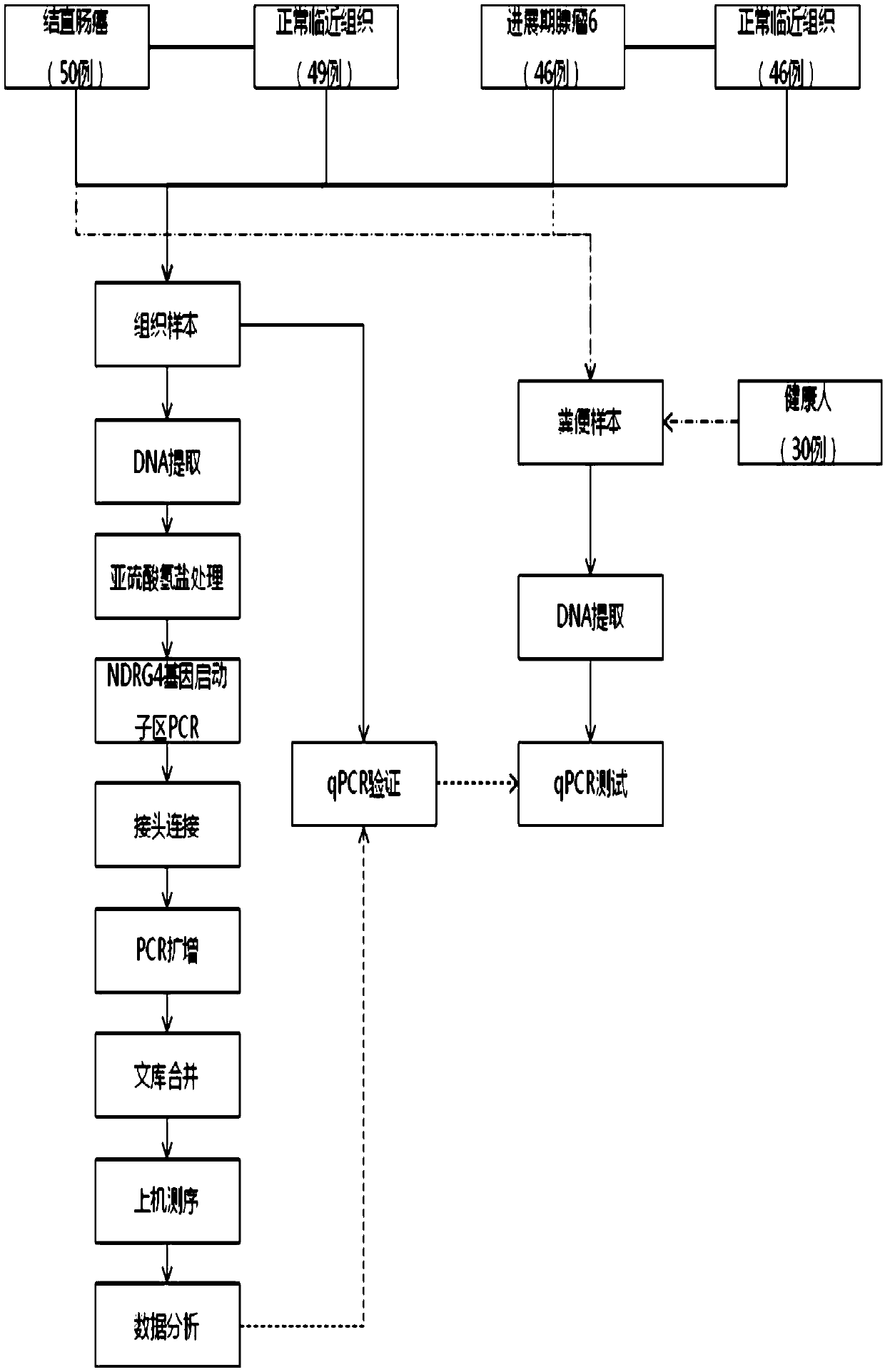

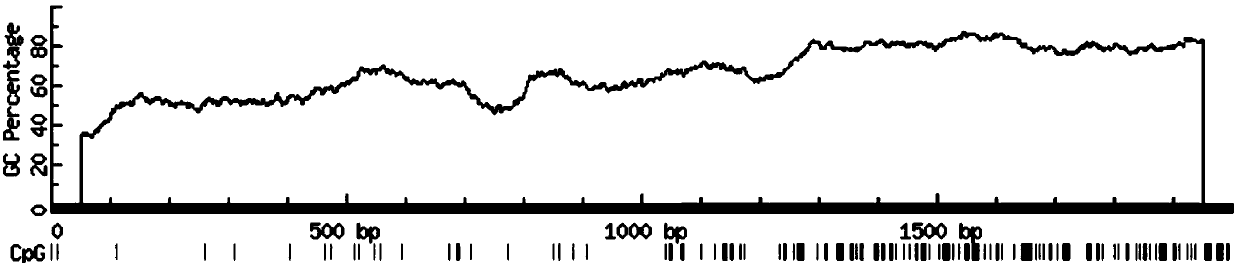

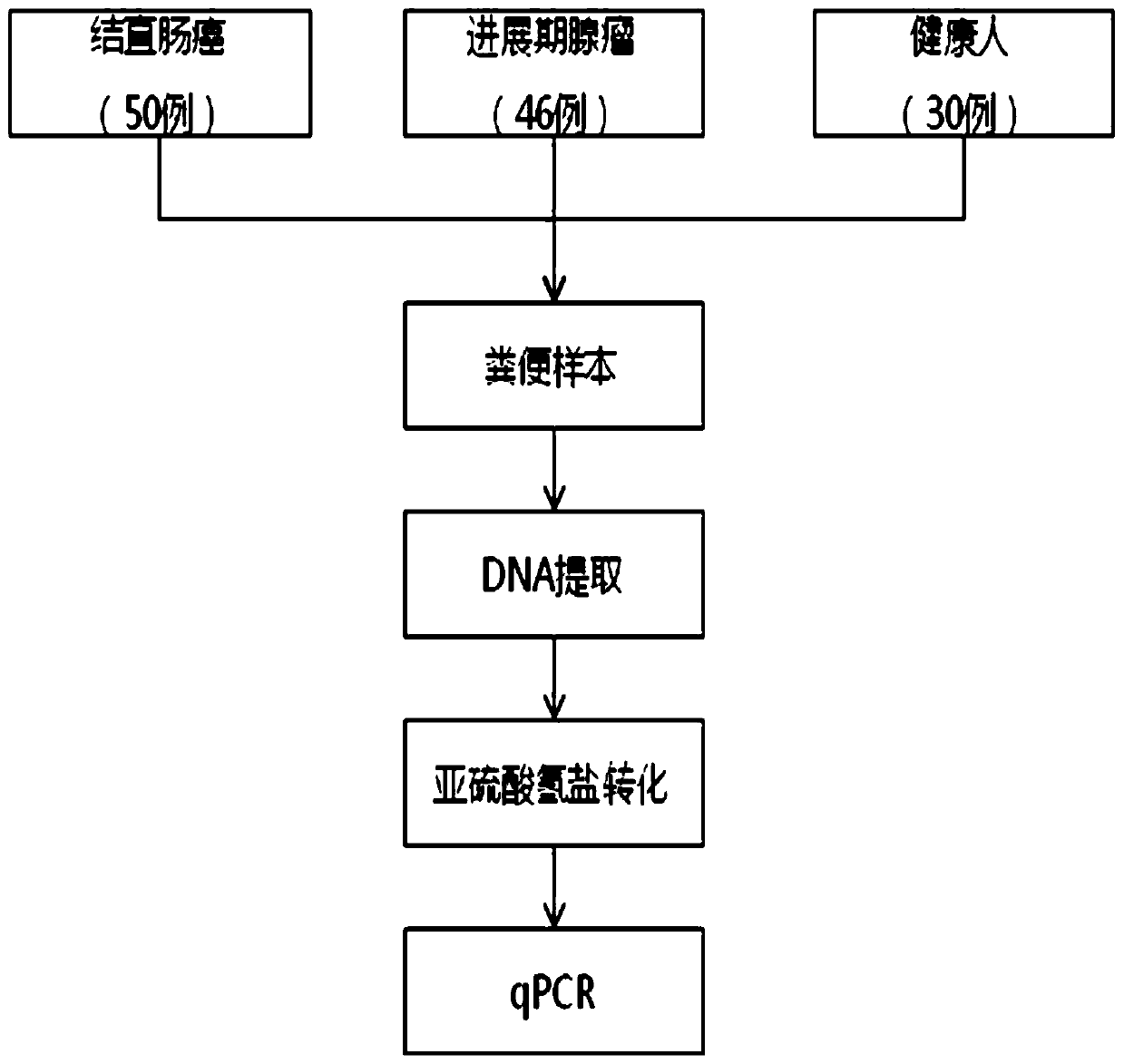

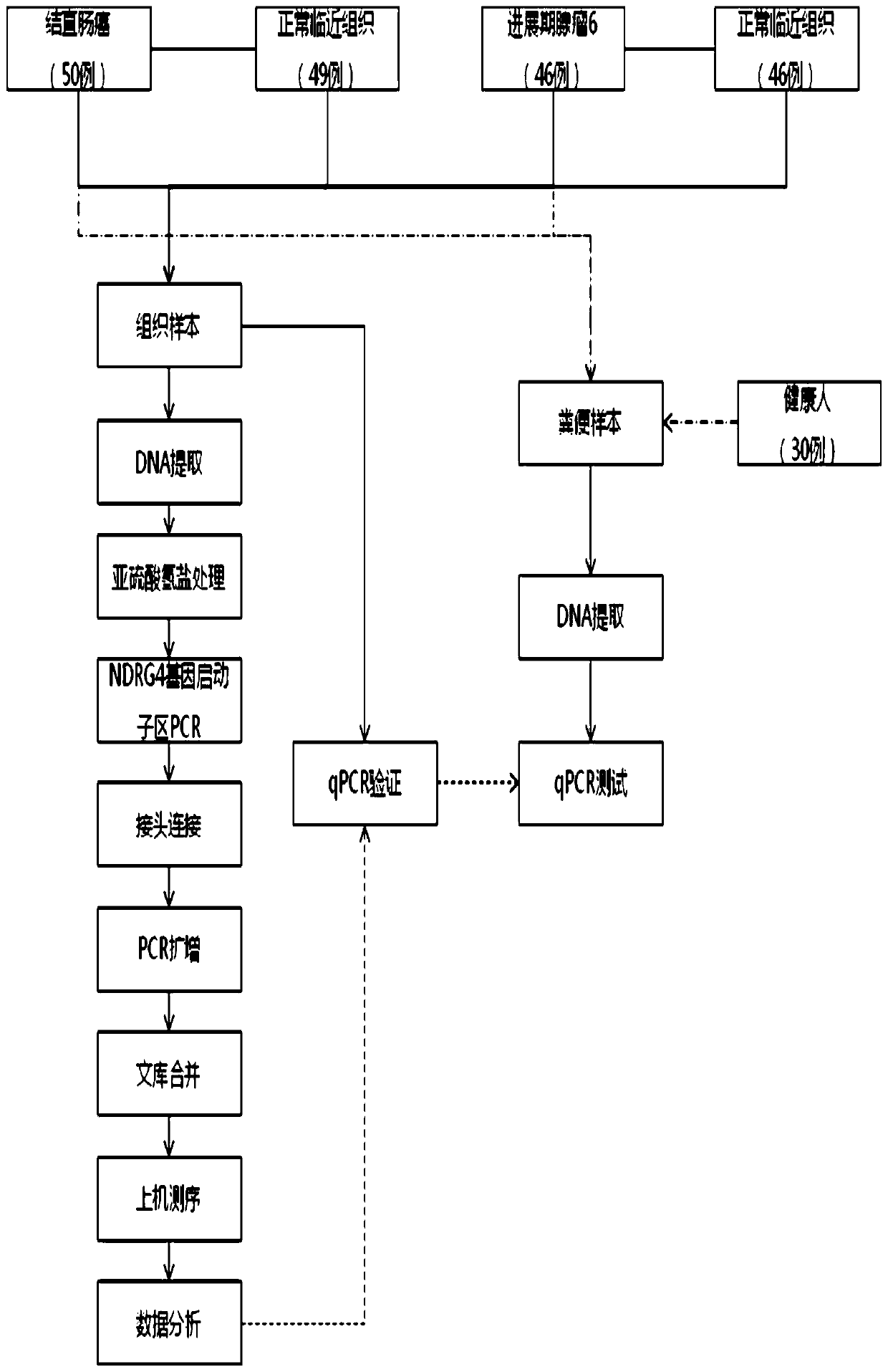

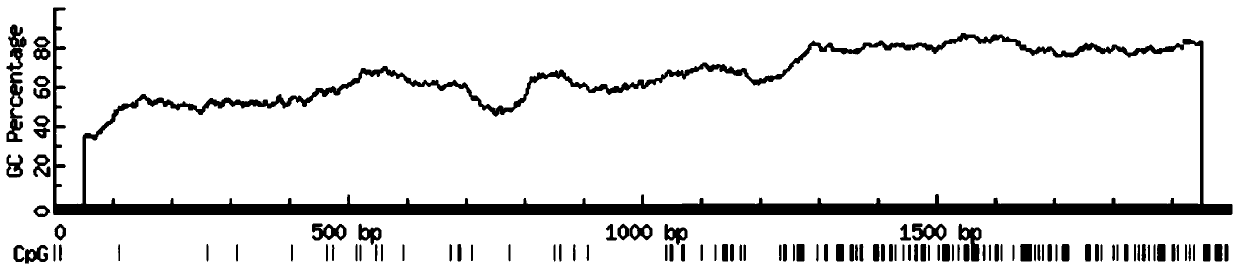

Method for early detection on colorectal cancer on basis of NDRG4 gene methylation sequence

ActiveCN108676878AAccurate detectionHigh sensitivityMicrobiological testing/measurementReference genesPcr assay

The invention discloses a method for early detection on a colorectal cancer on the basis of a NDRG4 gene methylation sequence. The auxiliary diagnosis is performed on the early colorectal cancer through detecting whether a section of methylation sequence of a NDRG4 gene promoter region is methylated or not; the method comprises the following steps: extracting DNA from tissue and fecal samples, treating with hydrosulfite, then performing real-time quantitative PCR determination and judging a methylation level through calculating whether an amplified Ct ratio difference value between a target gene NDRG4 and an internal reference gene B2M is within a decision critical value or not. The method is noninvasive and can be used for the auxiliary diagnosis of the early colorectal cancer.

Owner:HANGZHOU NEW HORIZON HEALTH TECH CO LTD

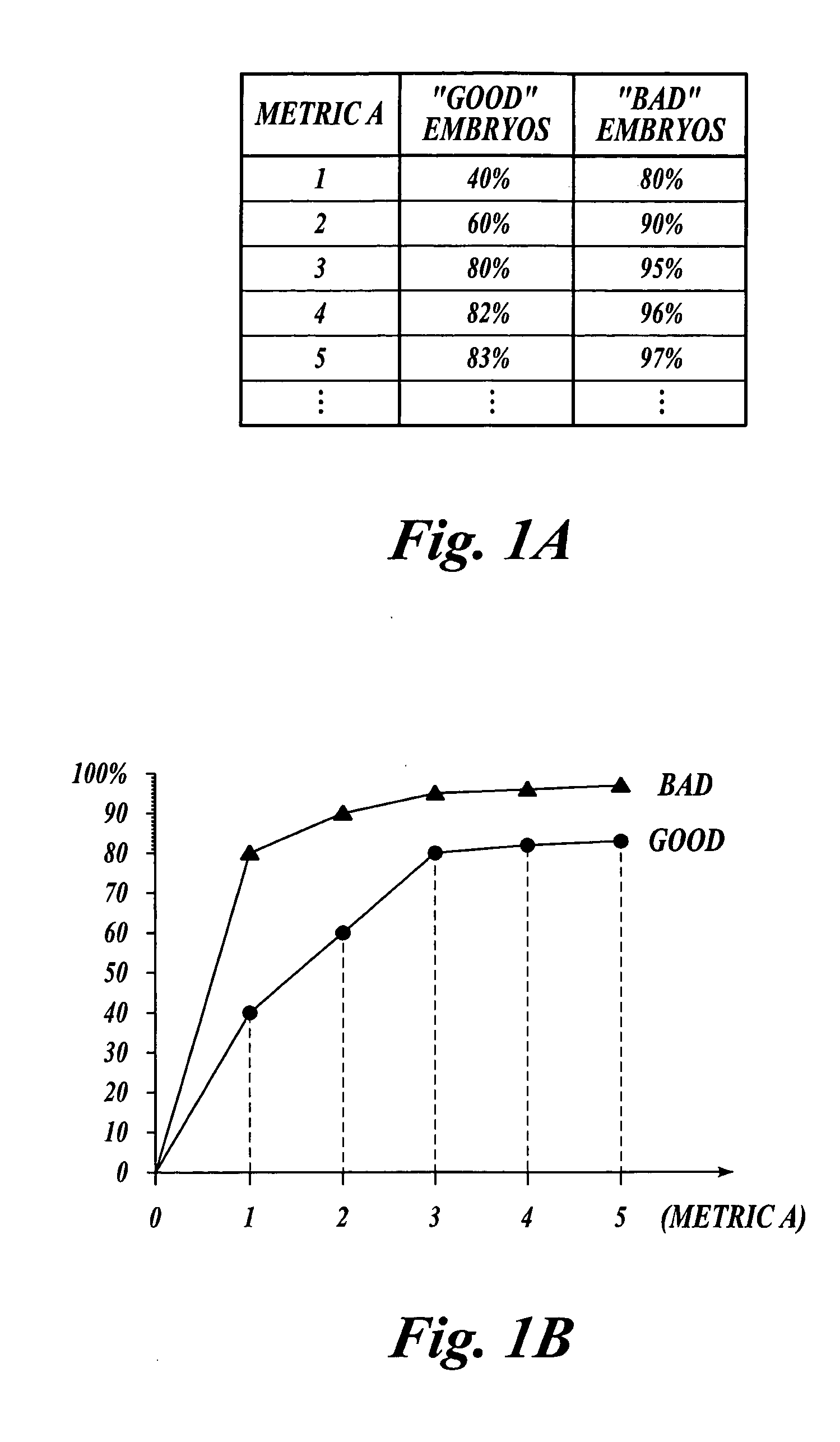

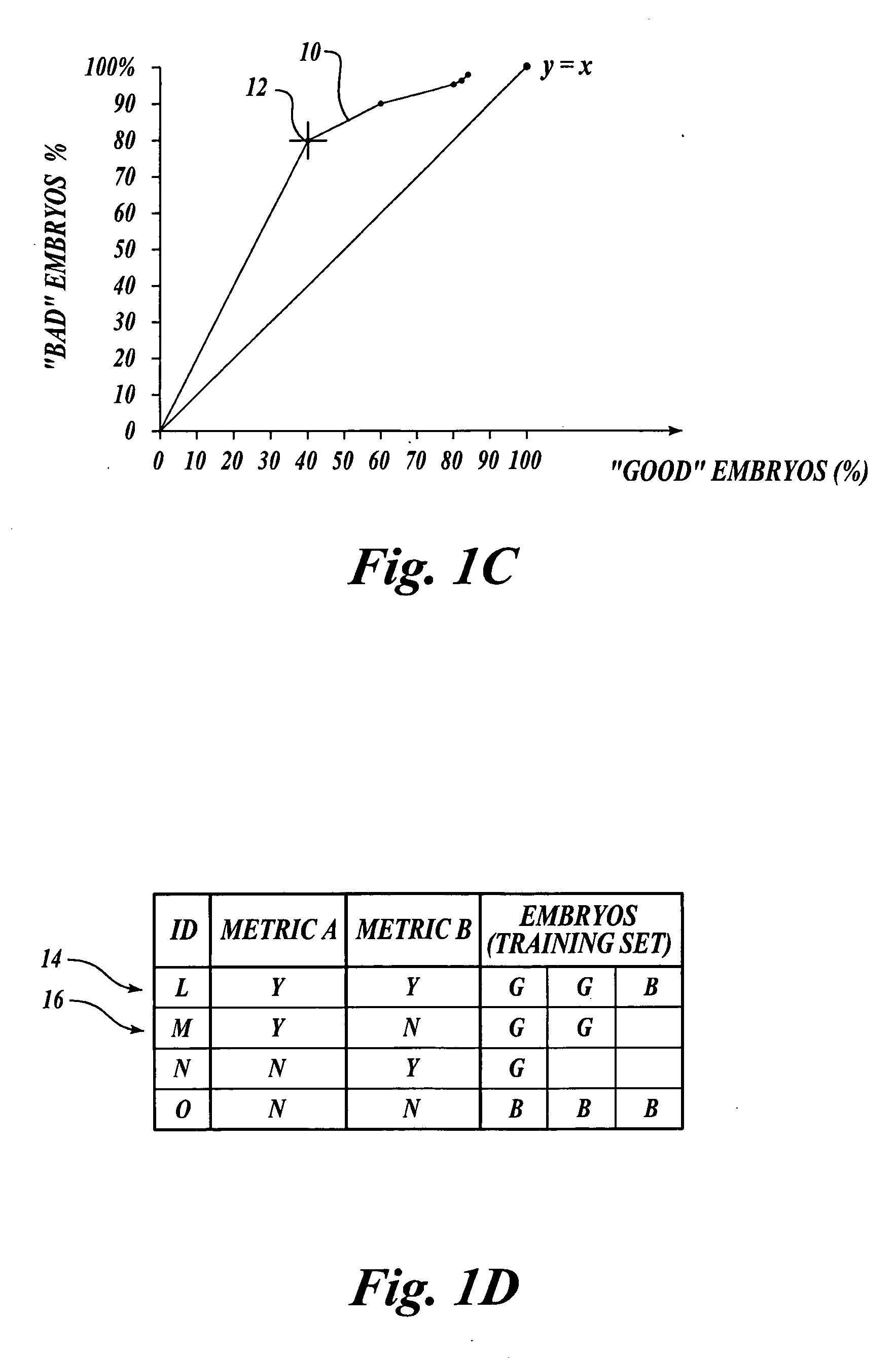

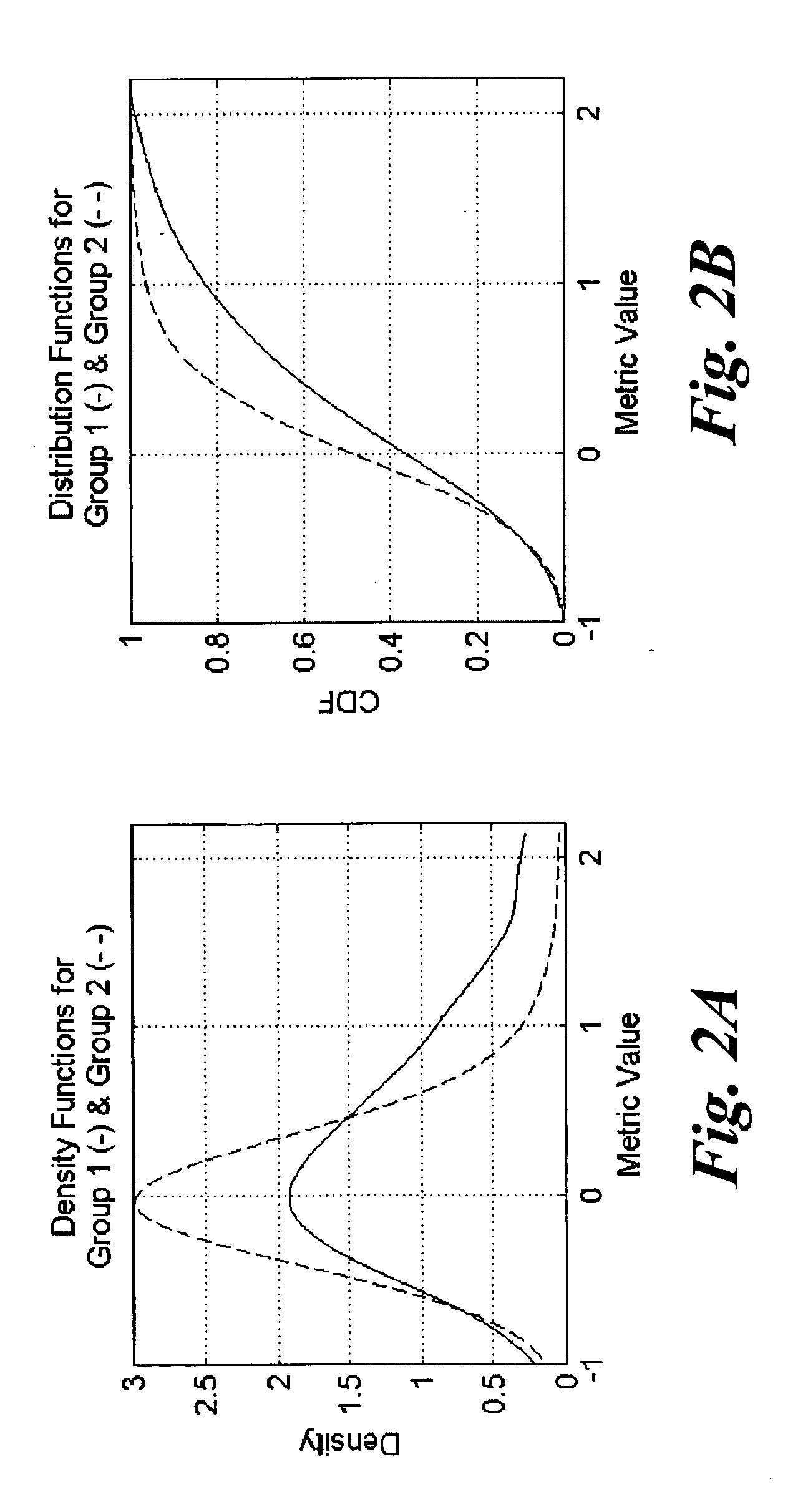

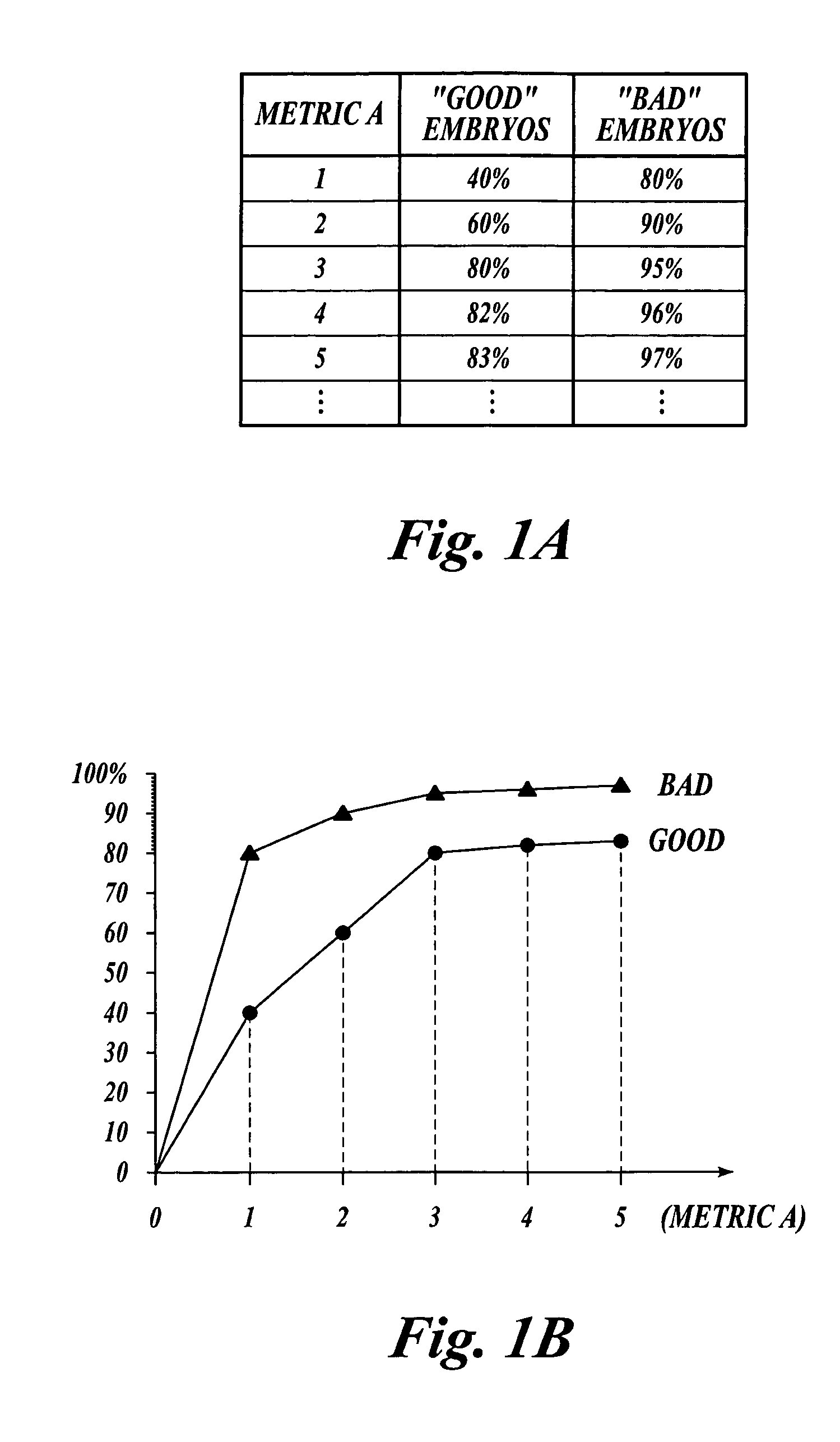

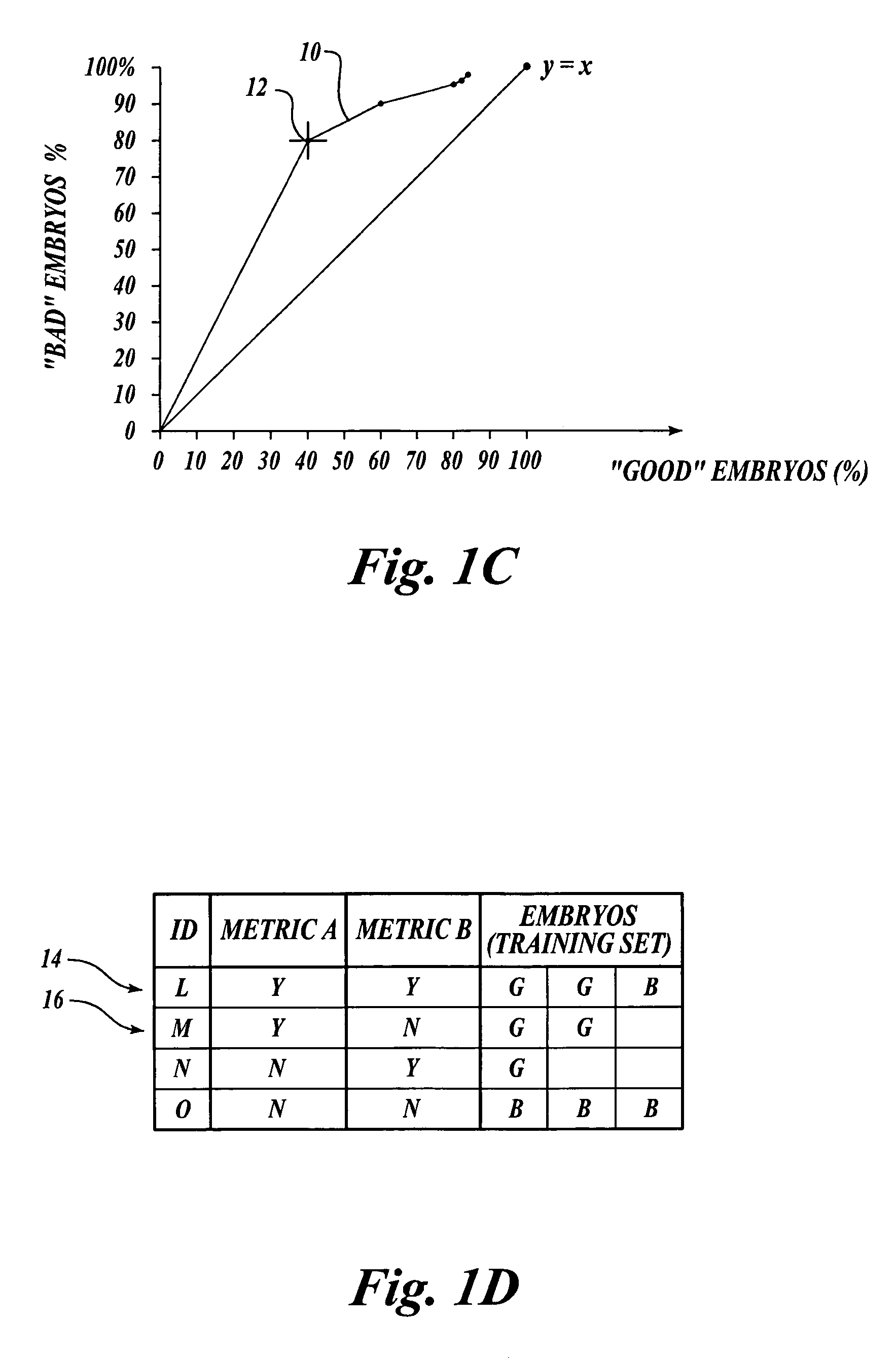

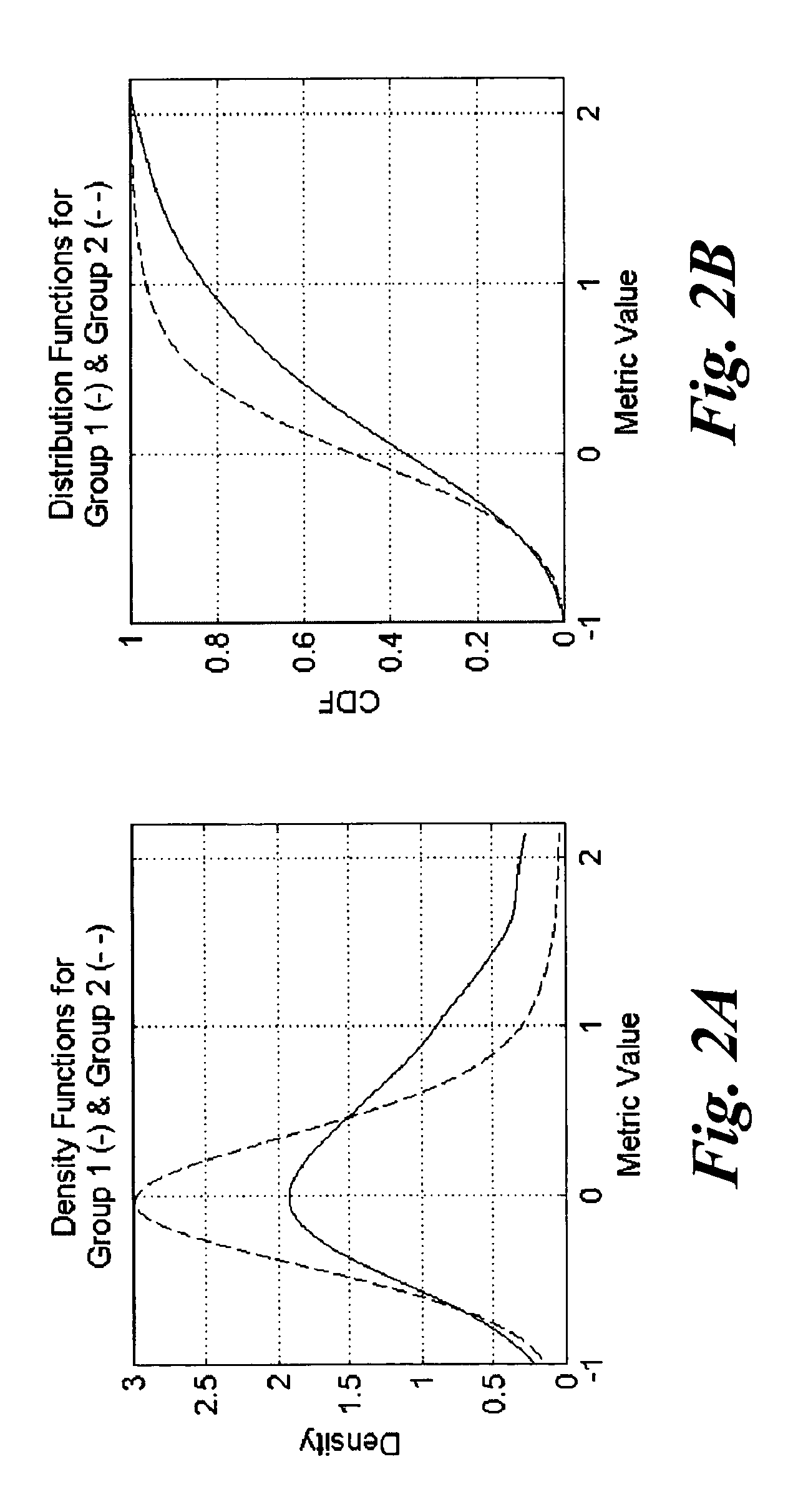

General method of classifying plant embryos using a generalized Lorenz-Bayes classifier

ActiveUS20050069176A1Process can be speededRigorous testingCharacter and pattern recognitionAgricultureEmbryoMulti dimensional

A method of classifying plant embryos according to their quality based on a general form of Lorenz-Bayes classifier is disclosed. First, image or spectral data of plant embryos of known quality are acquired, and the data are divided into two classes according to the embryos' known quality. Second, metrics are calculated from the acquired image or spectral data in each class. Third, multi-dimensional histograms of multiple metrics are prepared for both classes. Fourth, the difference or some other measure of comparison between the two multi-dimensional histograms is obtained. Fifth, image or spectral data of a plant embryo of unknown quality are obtained and metrics are calculated therefrom. Sixth, the embryo of unknown quality is assigned to a class based on its calculated metrics and the result of the comparison as calculated in the fourth step above.

Owner:WEYERHAEUSER NR CO

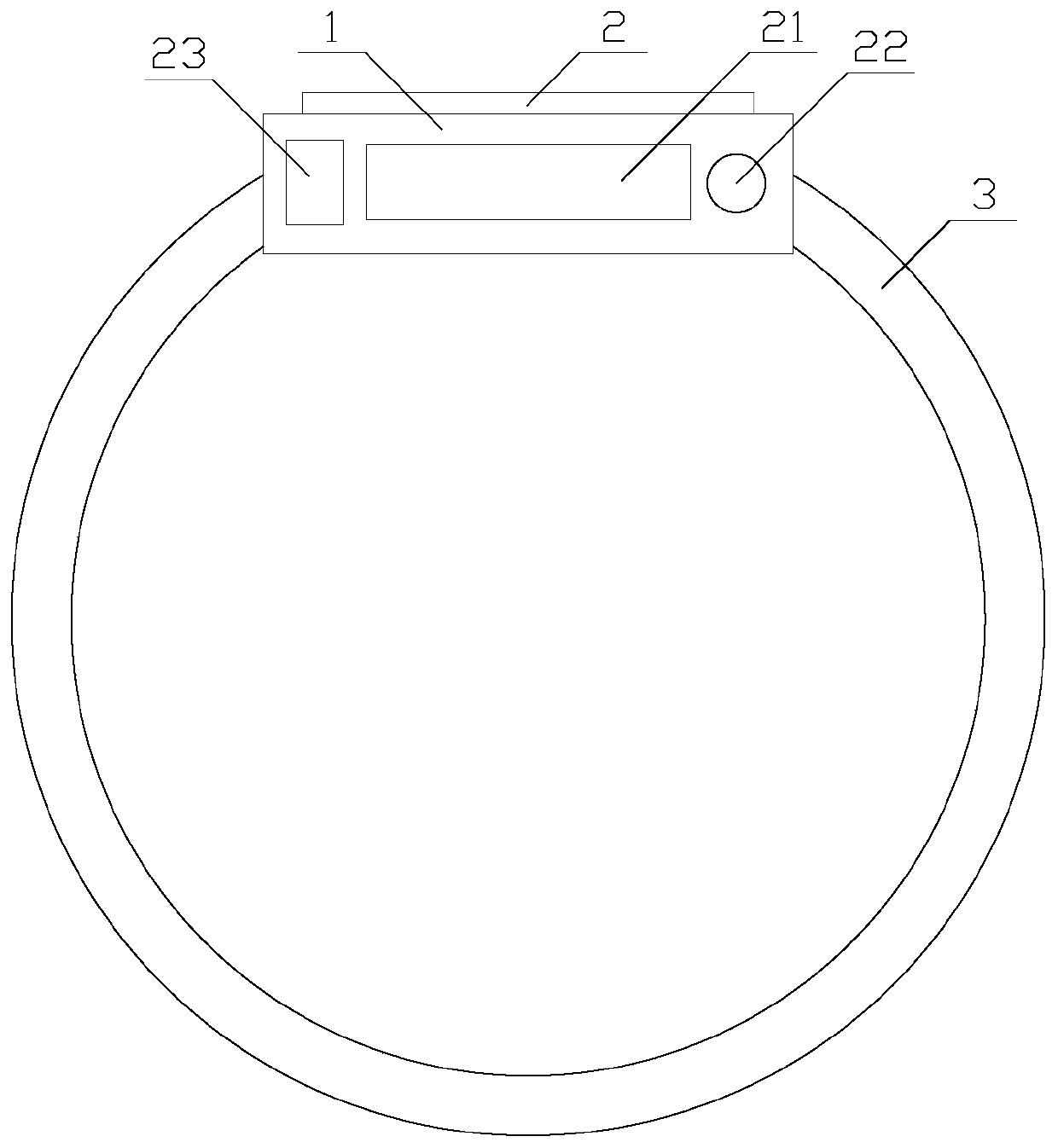

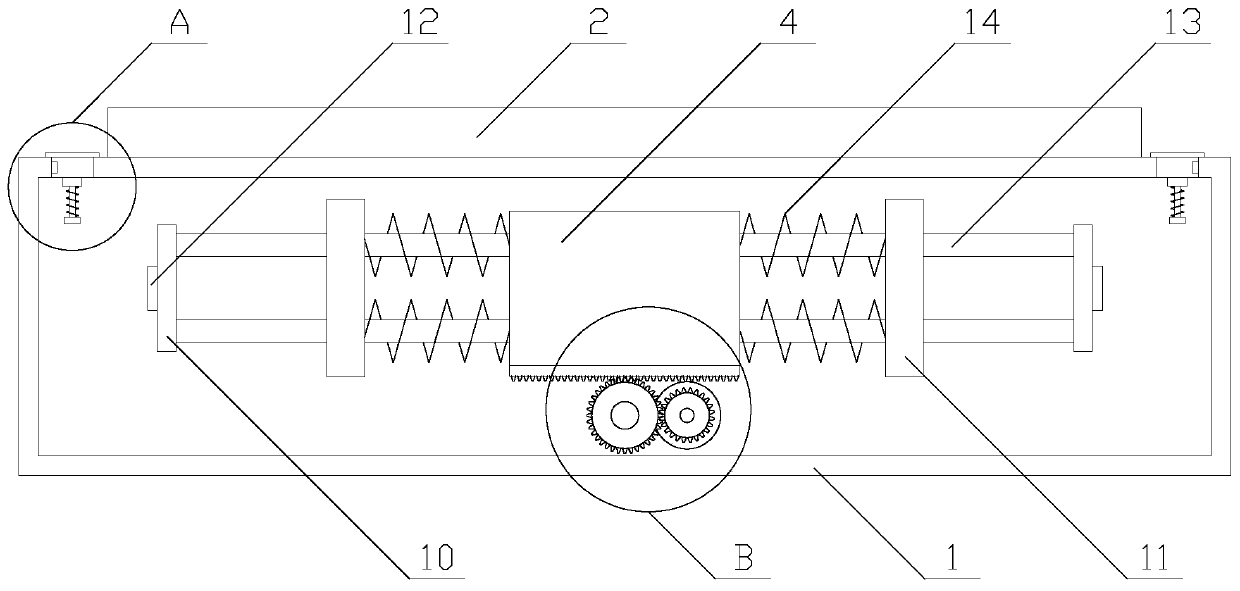

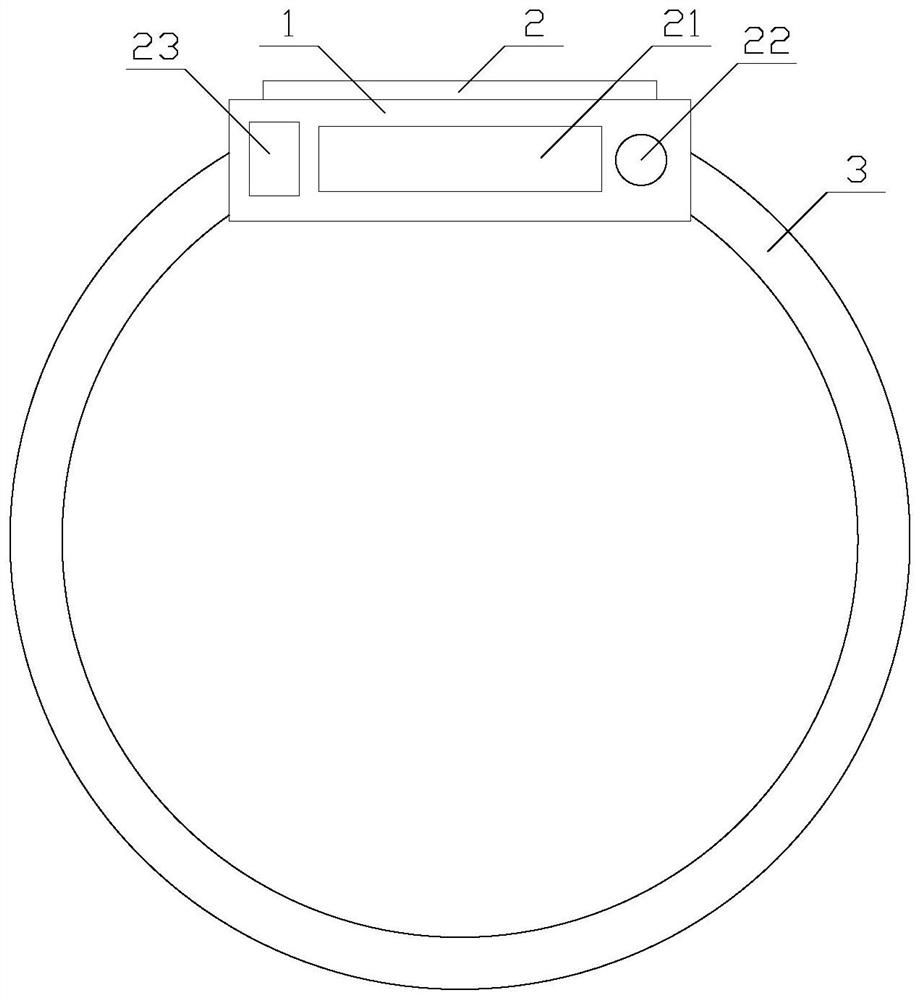

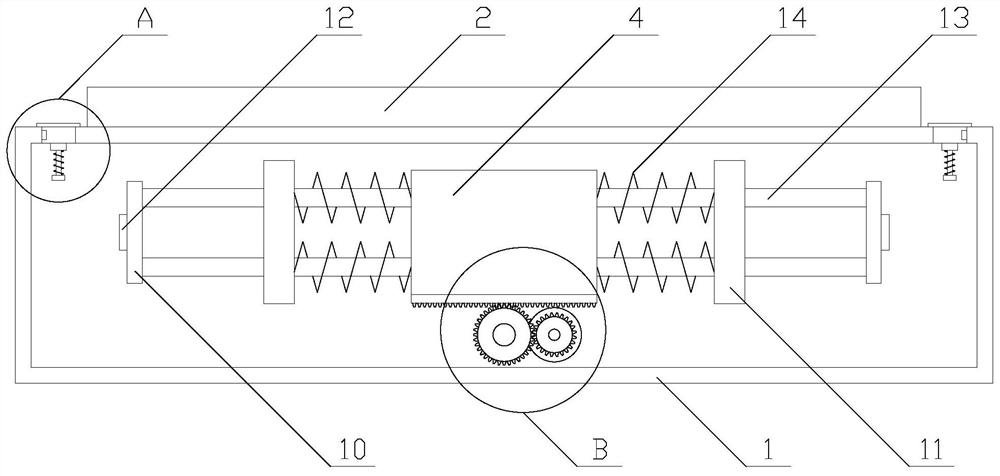

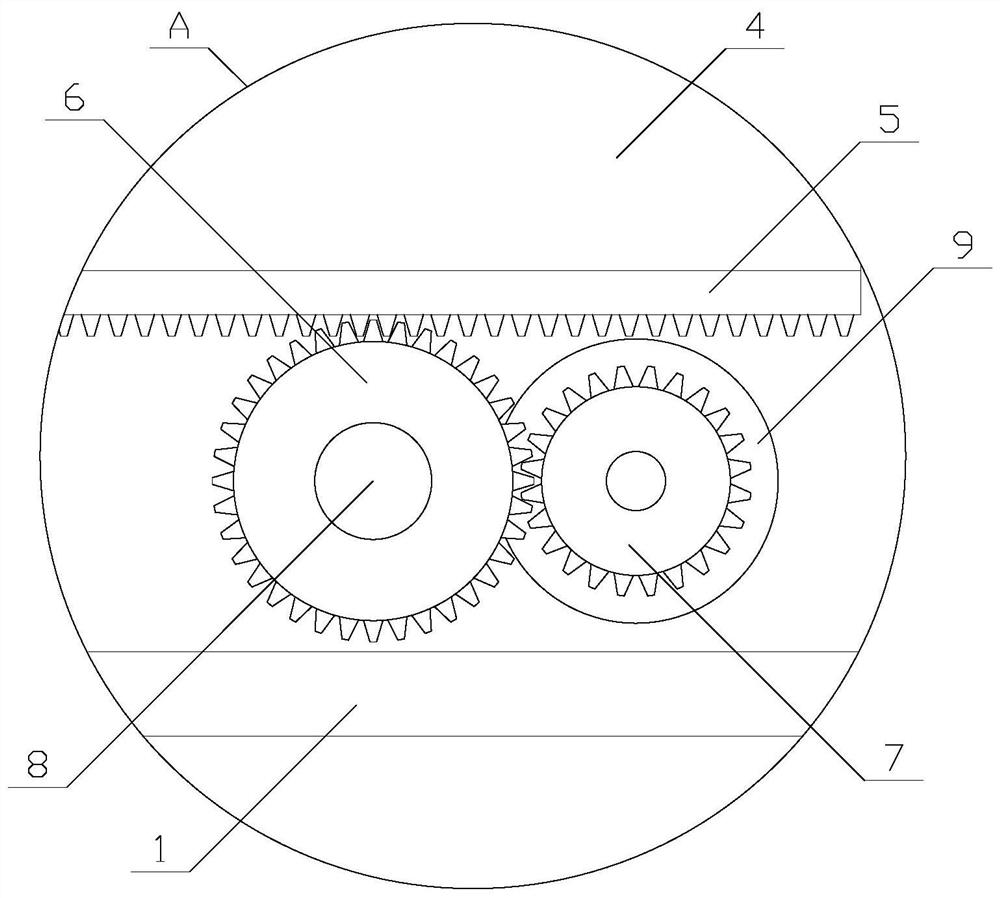

Medical intelligent bracelet with long endurance

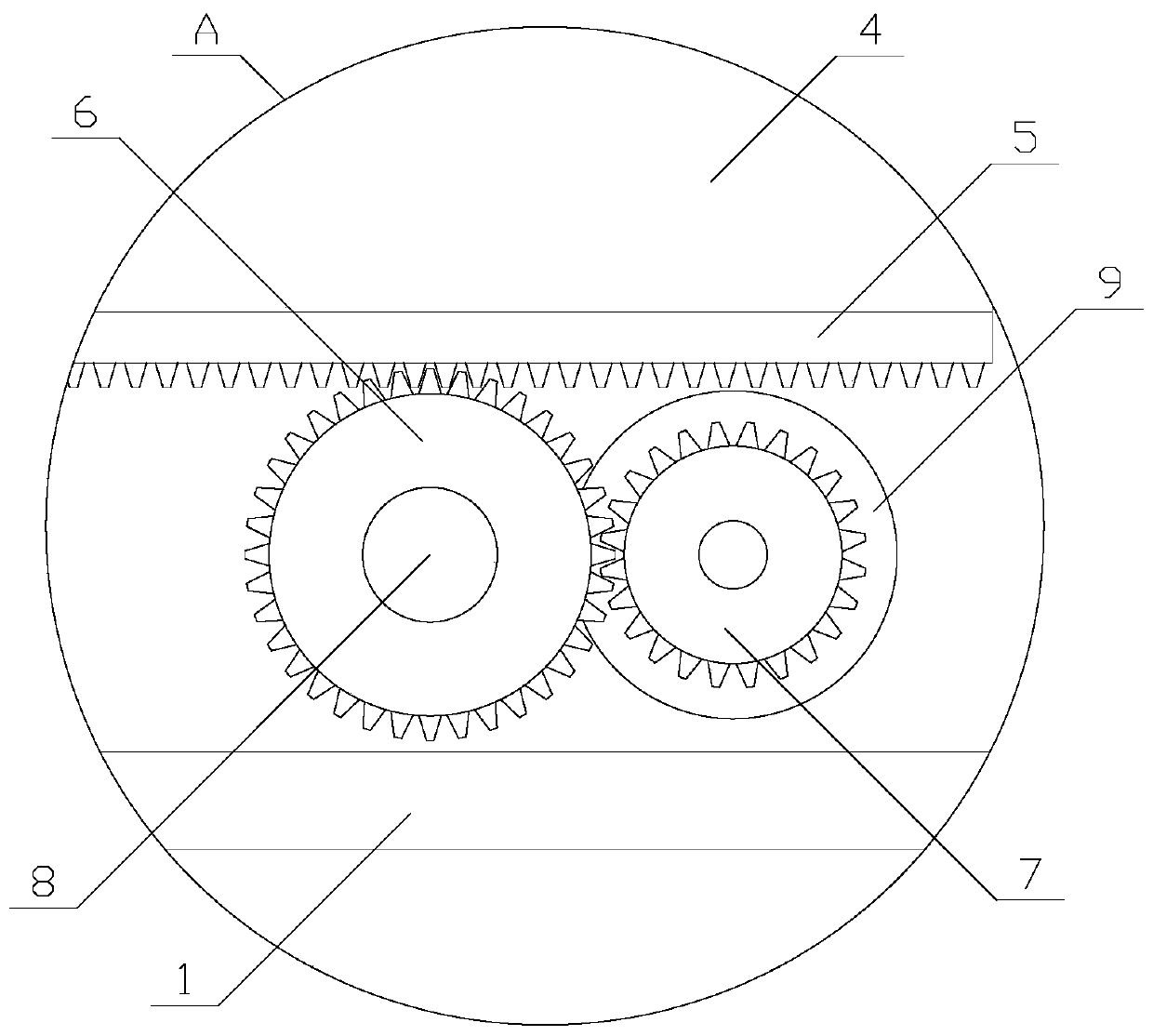

ActiveCN109744665AImprove battery lifePracticalBraceletsDiagnostic recording/measuringCircular discGear wheel

The invention relates to a medical intelligent bracelet with long endurance. The medical intelligent bracelet comprises a main body, a displaying screen and a ring belt; the displaying screen is arranged on the main body, and in a round-disc shape, the ring belt is fixed to the main body, a detection mechanism and an endurance mechanism are arranged in the main body, and the endurance mechanism comprises a movable block, a rack, a first gear, a second gear, a rotary shaft, a generator and two supporting assemblies, and each supporting assembly comprises a transmission block, a first sliding block, a touch sensor, two optical rods and two first springs, and the detection mechanism comprises at least two detection assemblies. The medical intelligent bracelet with long endurance achieves thepower generation function through the endurance mechanism, the endurance of the bracelet is enhanced, and in addition, the function that whether a user falls down or not is detected is realized through the detection mechanism.

Owner:山东鑫年信息科技有限公司

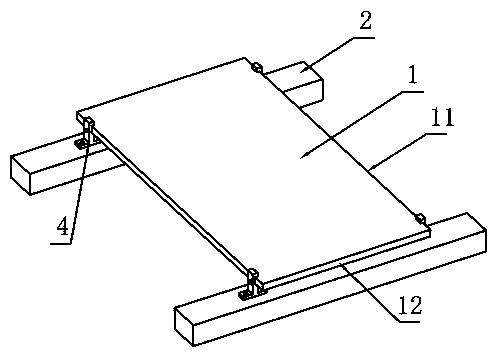

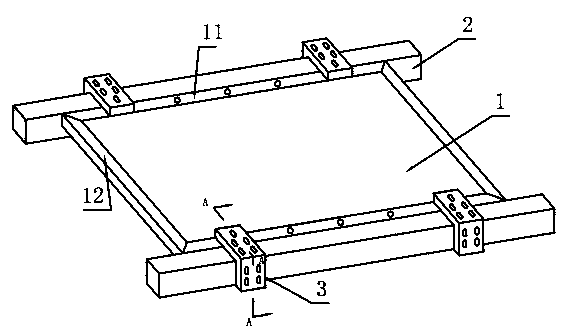

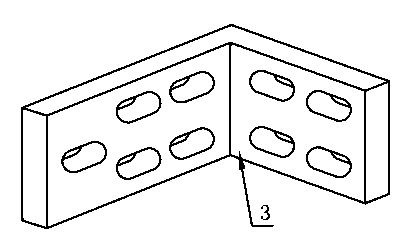

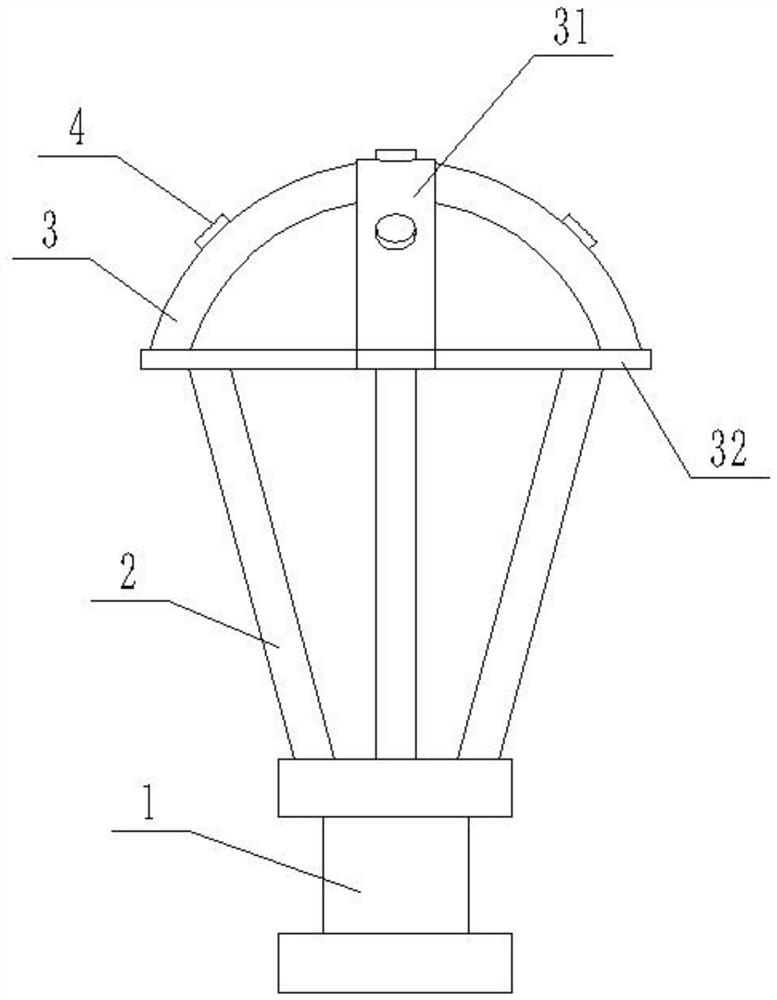

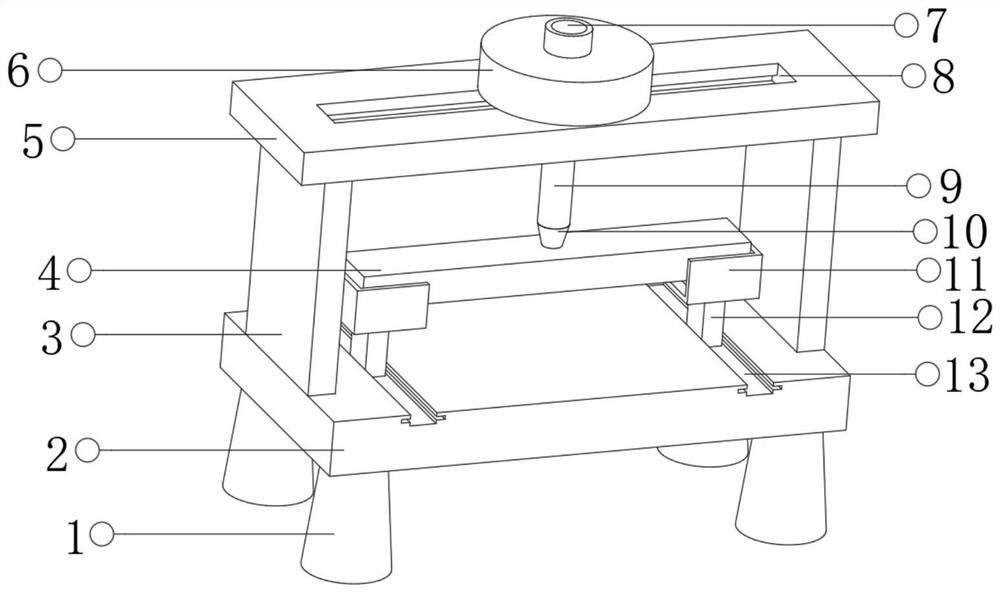

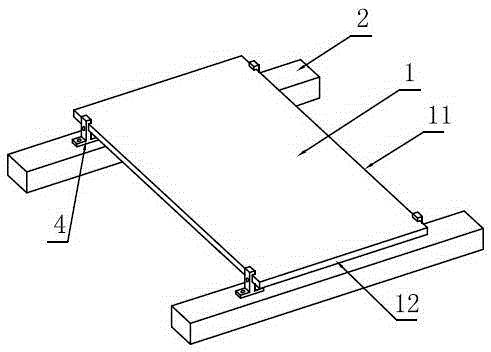

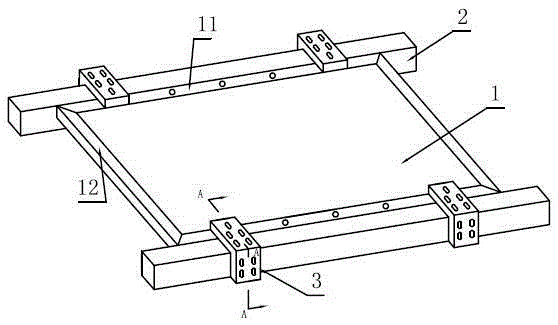

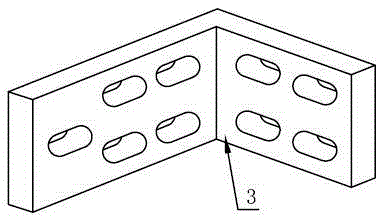

Clamping tool for testing mechanical load of photovoltaic module

ActiveCN103439183ARigorous testingImprove mechanical propertiesMaterial strength using tensile/compressive forcesMechanical loadElectrical and Electronics engineering

The invention discloses a clamping tool for testing the mechanical load of a photovoltaic module. The clamping tool comprises a pair of long cushion blocks arranged in parallel, wherein each long cushion block is provided with at least two clamps, the clamps are connected through bolts to fixedly connect an aluminum alloy guide rail onto the inner sides of the long cushion blocks, the length of the aluminum alloy guide rail is not less than that of each long side frame of the photovoltaic module, a slide slot for accommodating and clamping each long side frame of the photovoltaic module is arranged on the inner side of the aluminum alloy guide rail, the two slide slots of the aluminum alloy guide rail arranged on the two long cushion blocks are located at the same horizontal heights, so that the clamped photovoltaic module is guaranteed to be placed horizontally. According to the clamping tool provided by the invention, the reliability of a test result is improved, the mechanical load test is more precise, and the comprehensive mechanical performance of the photovoltaic module passing the test is better.

Owner:赣州爱康光电科技有限公司

General method of classifying plant embryos using a generalized Lorenz-Bayes classifier

ActiveUS8691575B2Improve classificationImprove classification accuracyCharacter and pattern recognitionTissue cultureEmbryoMulti dimensional

A method of classifying plant embryos according to their quality based on a general form of Lorenz-Bayes classifier is disclosed. First, image or spectral data of plant embryos of known quality are acquired, and the data are divided into two classes according to the embryos' known quality. Second, metrics are calculated from the acquired image or spectral data in each class. Third, multi-dimensional histograms of multiple metrics are prepared for both classes. Fourth, the difference or some other measure of comparison between the two multi-dimensional histograms is obtained. Fifth, image or spectral data of a plant embryo of unknown quality are obtained and metrics are calculated therefrom. Sixth, the embryo of unknown quality is assigned to a class based on its calculated metrics and the result of the comparison as calculated in the fourth step above.

Owner:WEYERHAEUSER NR CO

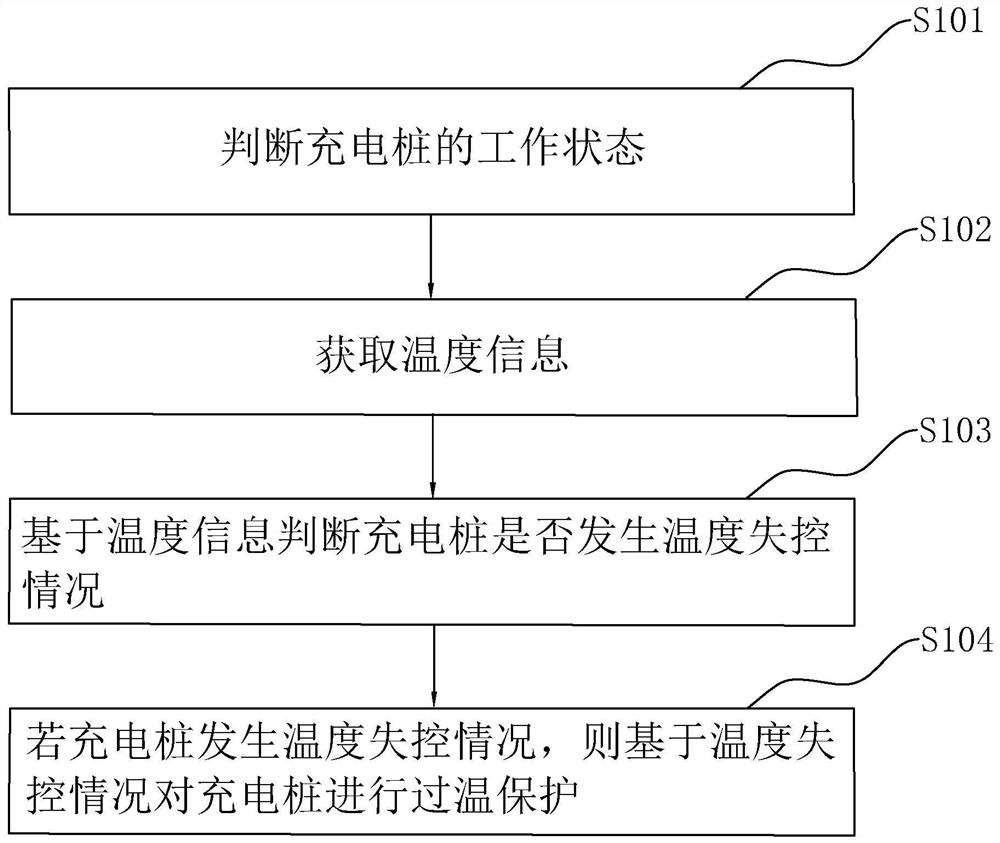

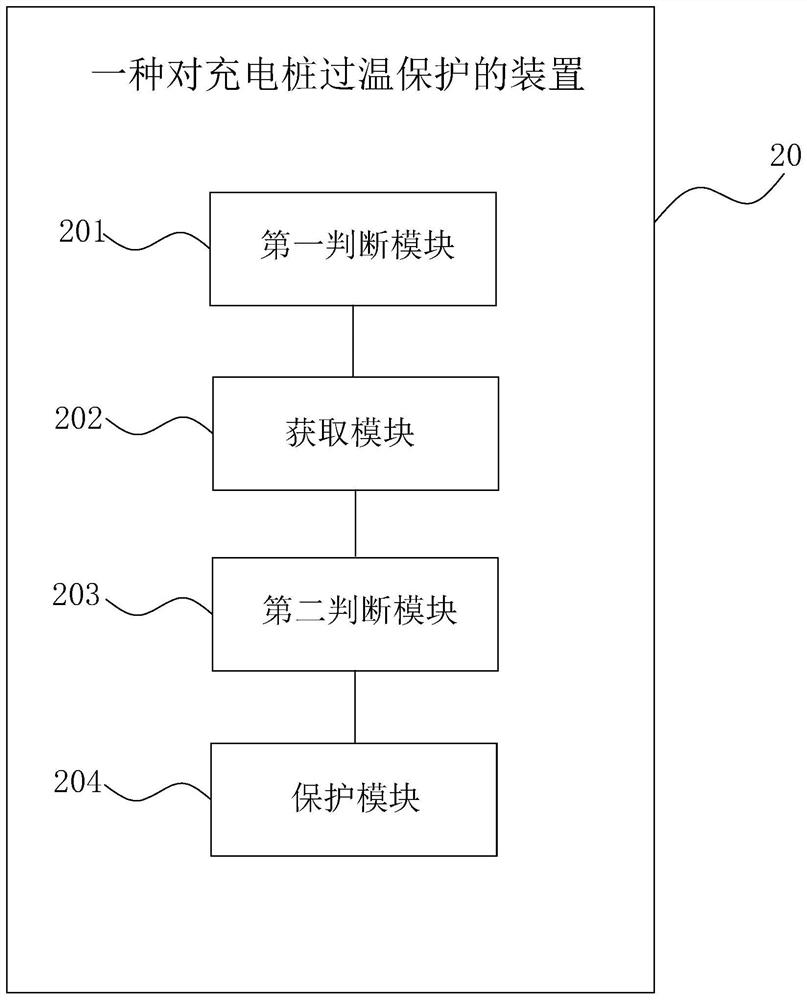

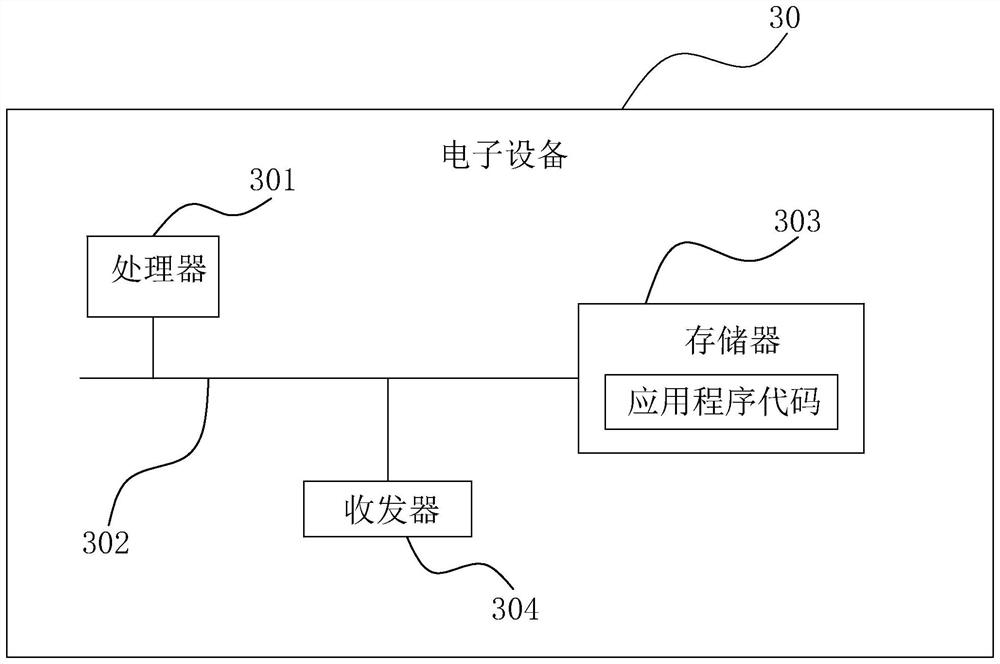

Method and device for over-temperature protection of charging pile, electronic equipment and medium

ActiveCN114148197AReduce the temperatureLow powerCharging stationsEmergency protective arrangements for automatic disconnectionProcess engineeringMechanical engineering

The invention relates to an over-temperature protection method and device for a charging pile, electronic equipment and a medium, and relates to the technical field of charging piles, the method comprises the steps that the working state of the charging pile is judged, and the working state comprises the charging state and the standby state; temperature information is obtained, wherein the temperature information comprises an air inlet temperature value, an air outlet temperature value and a control cabinet temperature value; judging whether the temperature of the charging pile is out of control based on the temperature information; and if the temperature out-of-control condition occurs in the charging pile, over-temperature protection is performed on the charging pile based on the temperature out-of-control condition, and the over-temperature protection comprises reduction of the power of the charging pile. The charging pile has the effect of improving cooling and heat dissipation when the charging pile generates high temperature.

Owner:BEIJING X CHARGE TECH CO LTD

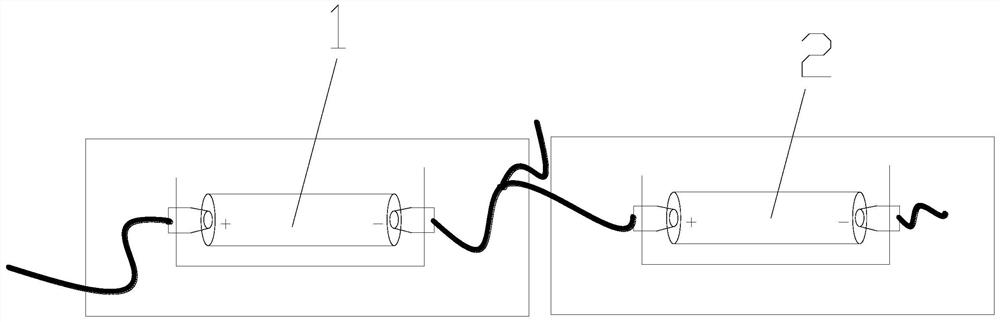

Lithium battery overdischarge test method

InactiveCN111983481AMeet the requirement of continuous discharge for 90minRigorous testingElectrical testingCharge currentEngineering

The invention discloses a lithium battery overdischarge test method which is characterized by comprising the following steps: connecting a first battery and a second battery in series to form a seriesbattery pack; performing constant-current charging on the first battery and the second battery to the charging termination voltage of the batteries by using the current I1, wherein I1 is the one-hourrate discharge current of the first battery; then respectively carrying out constant-voltage charging on the first battery and the second battery by using a charging termination voltage, stopping charging when the charging current is reduced to 0.05 I1 in the constant-voltage charging process, and standing for a period of time t1; discharging the first battery for 60 min at the constant current I1, then discharging the series battery pack composed of the first battery and the second battery for 30 min at the constant current I1, and detecting the voltage and the temperature of the first battery in real time in the discharging process. The test method provided by the invention is simple to operate and low in cost, and can meet the test requirement of continuously discharging the battery for 90min.

Owner:SUZHOU ANKAO ENERGY

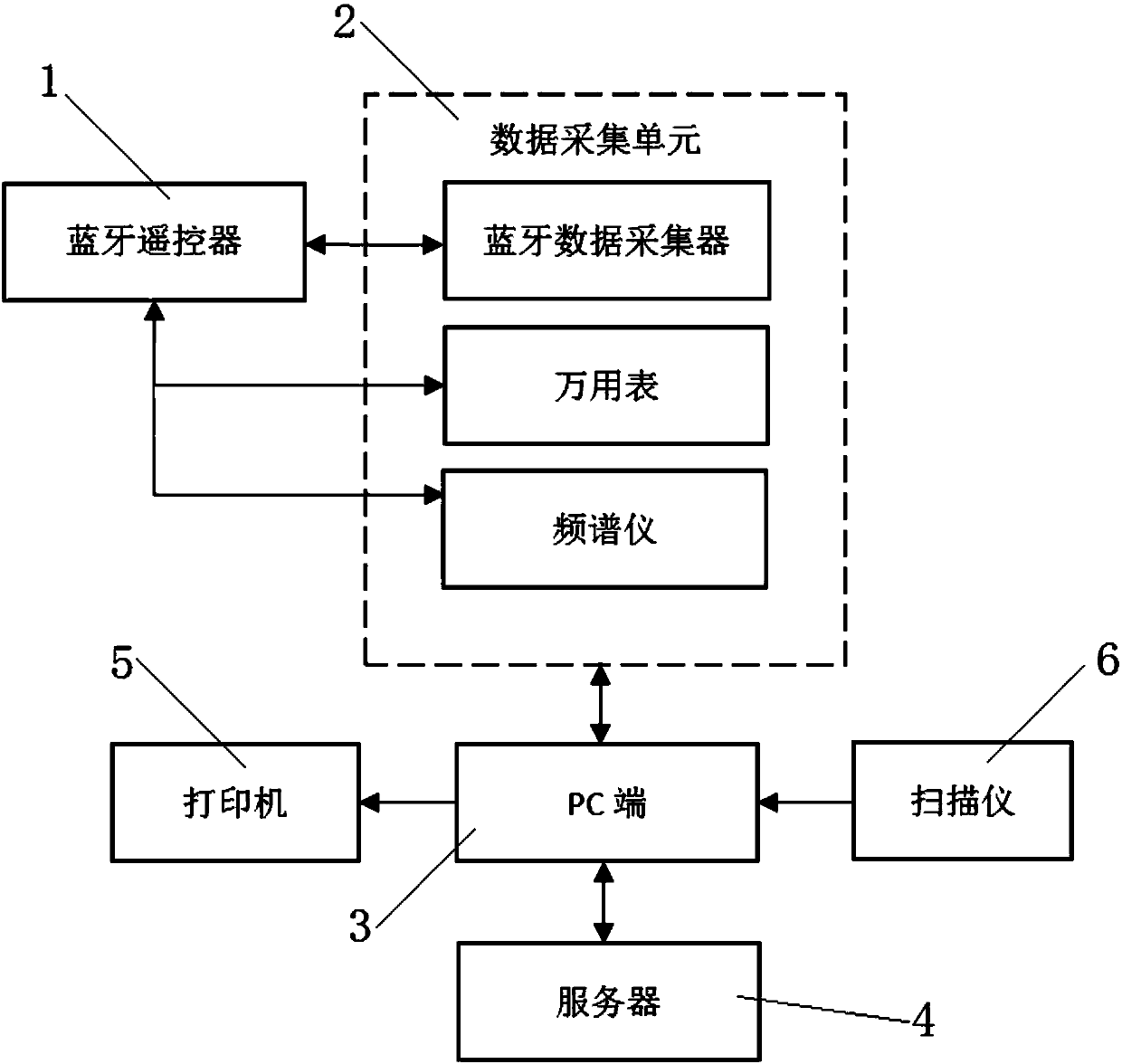

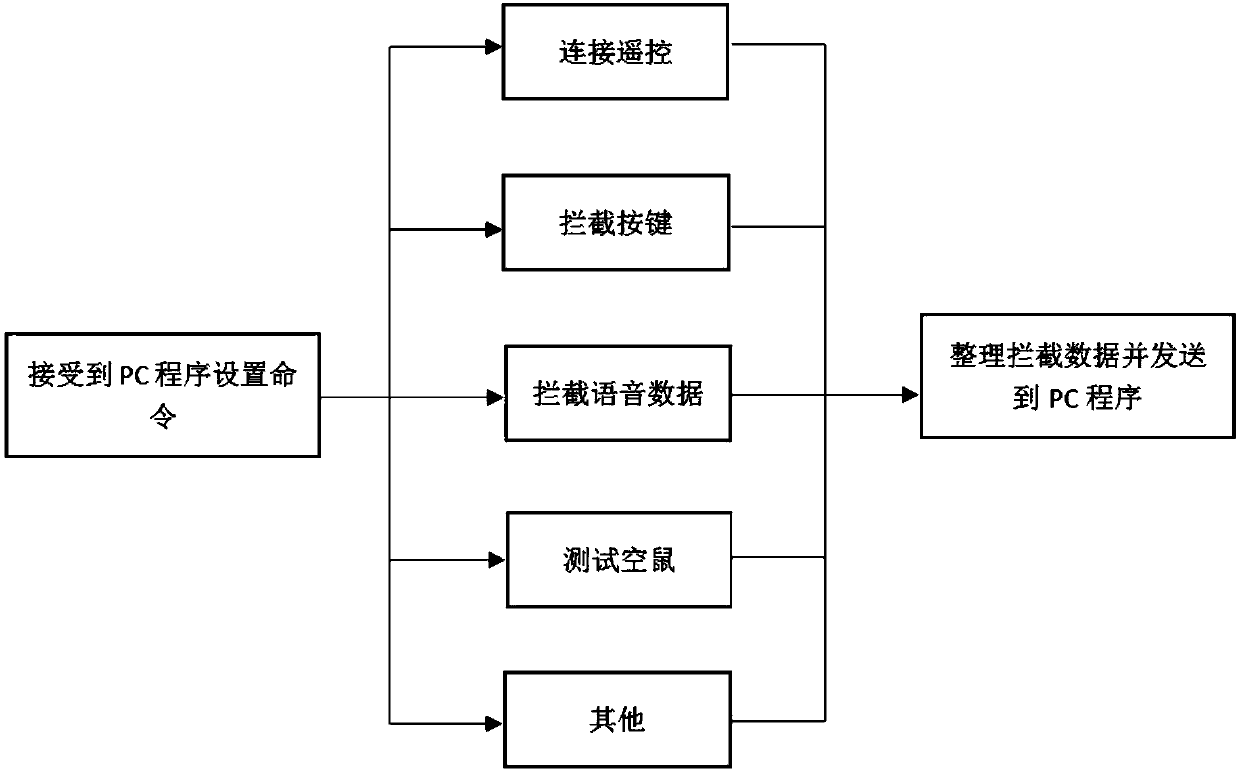

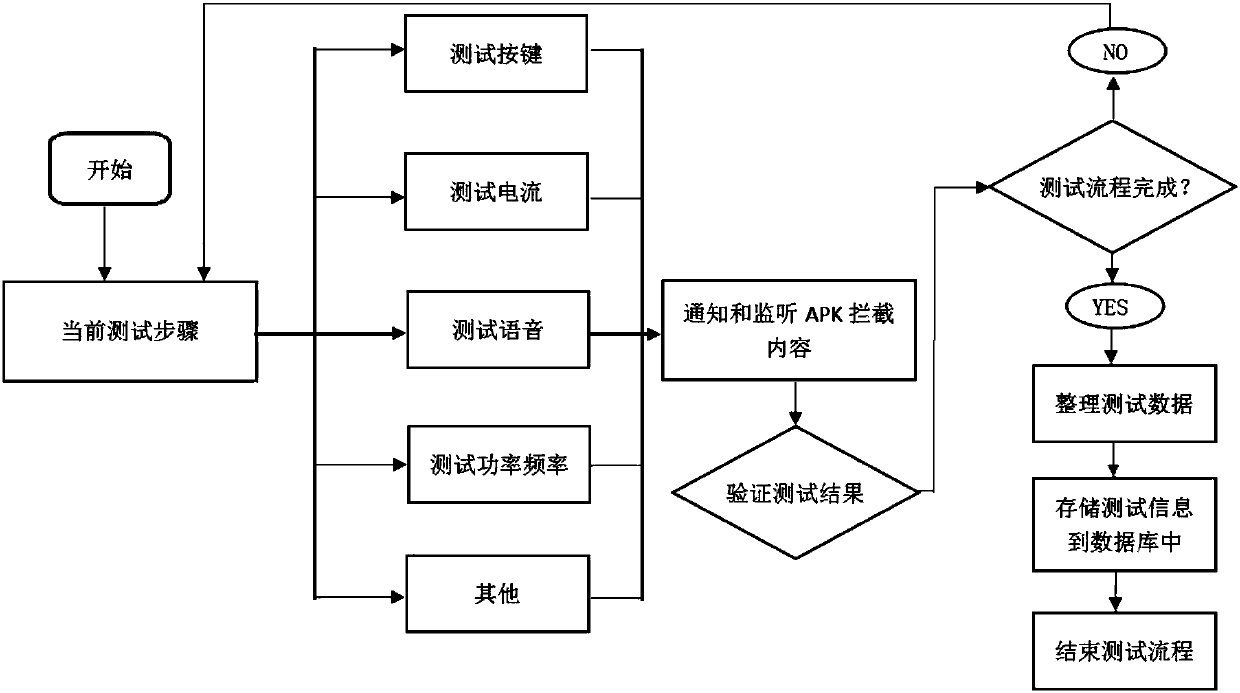

Bluetooth remote control testing management system and method

InactiveCN107909803AReduce stepsAvoid false positivesNon-electrical signal transmission systemsData informationRemote control

The invention discloses a Bluetooth remote control testing management system and method. An output end of a Bluetooth remote control is connected with a data acquisition unit, an output end of the data acquisition unit is connected with a PC terminal, an output end of the PC terminal is connected with a server, and the PC terminal is further connected with a printer and a scanner. The testing management method includes steps: an APK (Android package) of the Bluetooth remote control receives PC monitoring software commands from the PC terminal and intercepts remote control data to upload to PCsoftware through a TCP (transmission control protocol); the PC software receives and verifies information intercepted by the APK to check whether data information can be passed or not and finally sorts and uploads test data to a server terminal to display and store test results; the server terminal manages the test data and manages login users and test software. The software is responsible for allfunctional tests, so that manual operating steps are sharply reduced, and the problem of misjudgment caused by manual operation can be avoided. In addition, data traceability, test preciseness and high reliability are realized.

Owner:GUANGDONG SENEASY INTELLIGENT TECH CO LTD

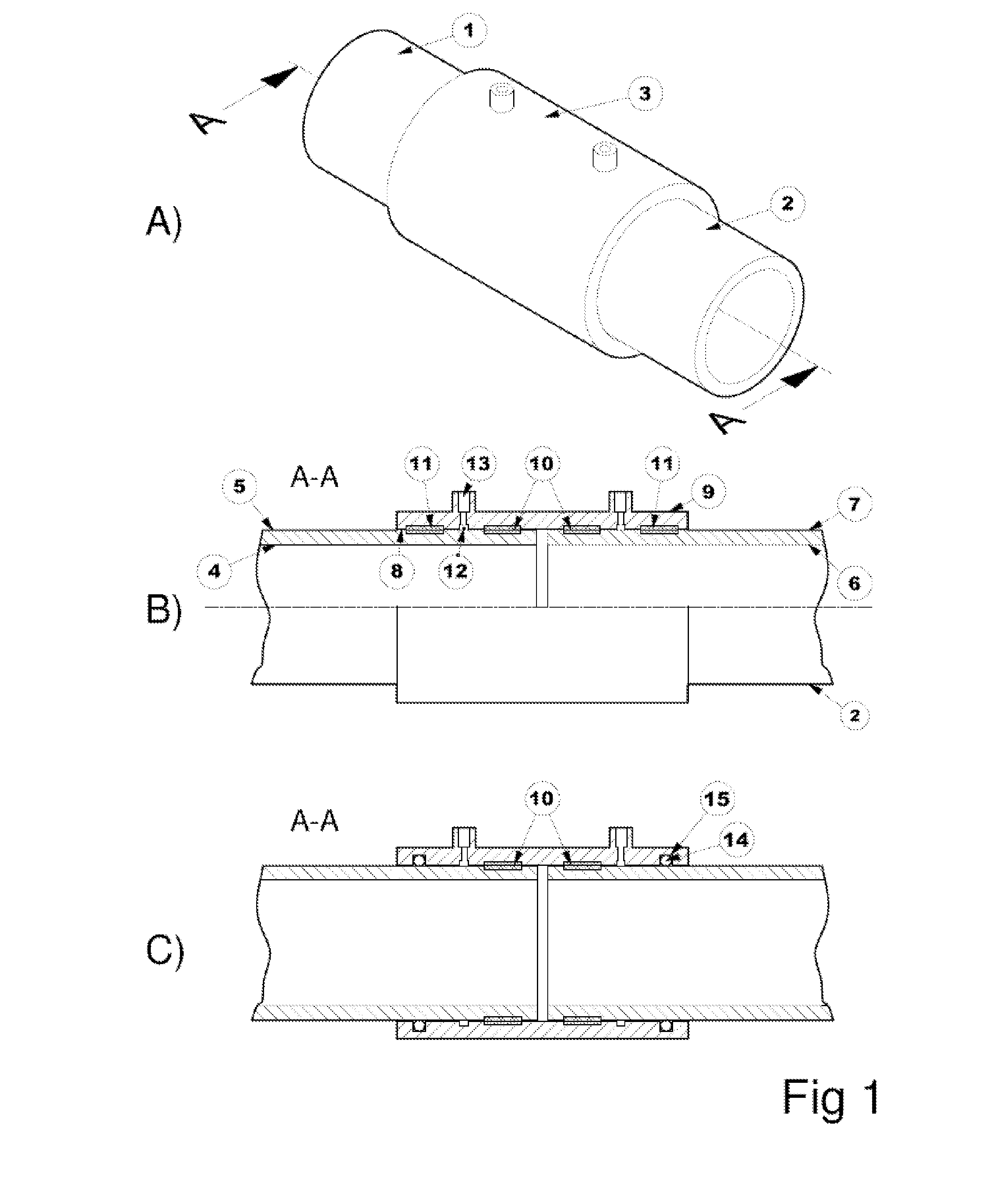

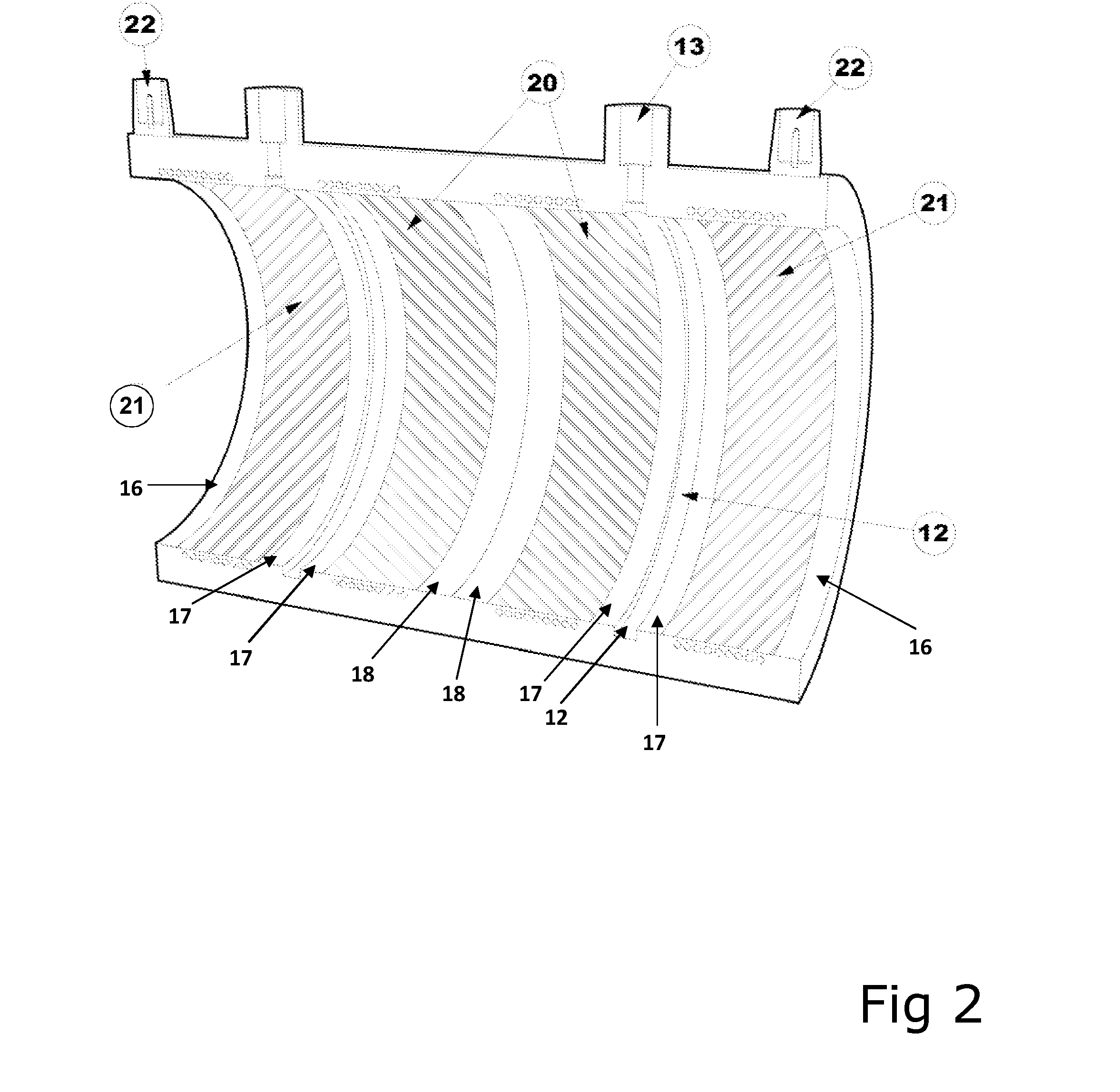

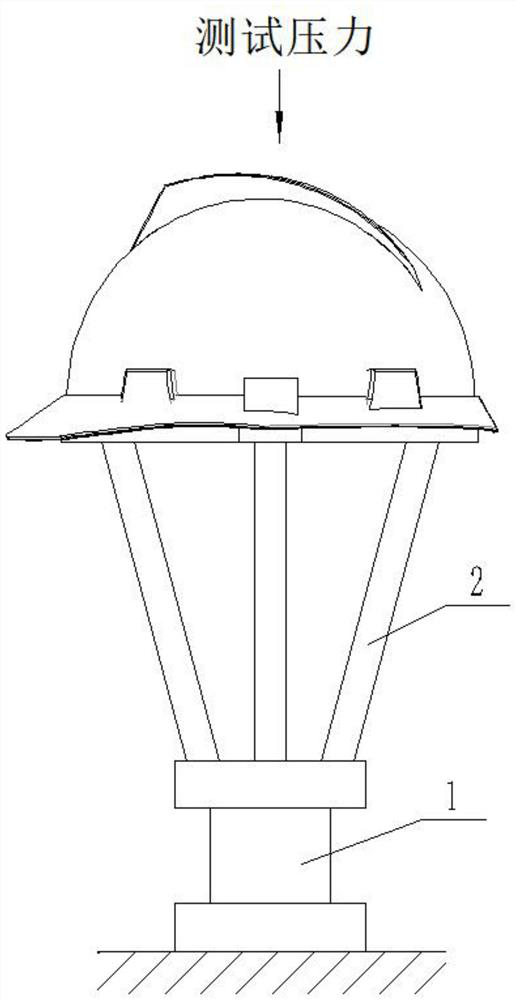

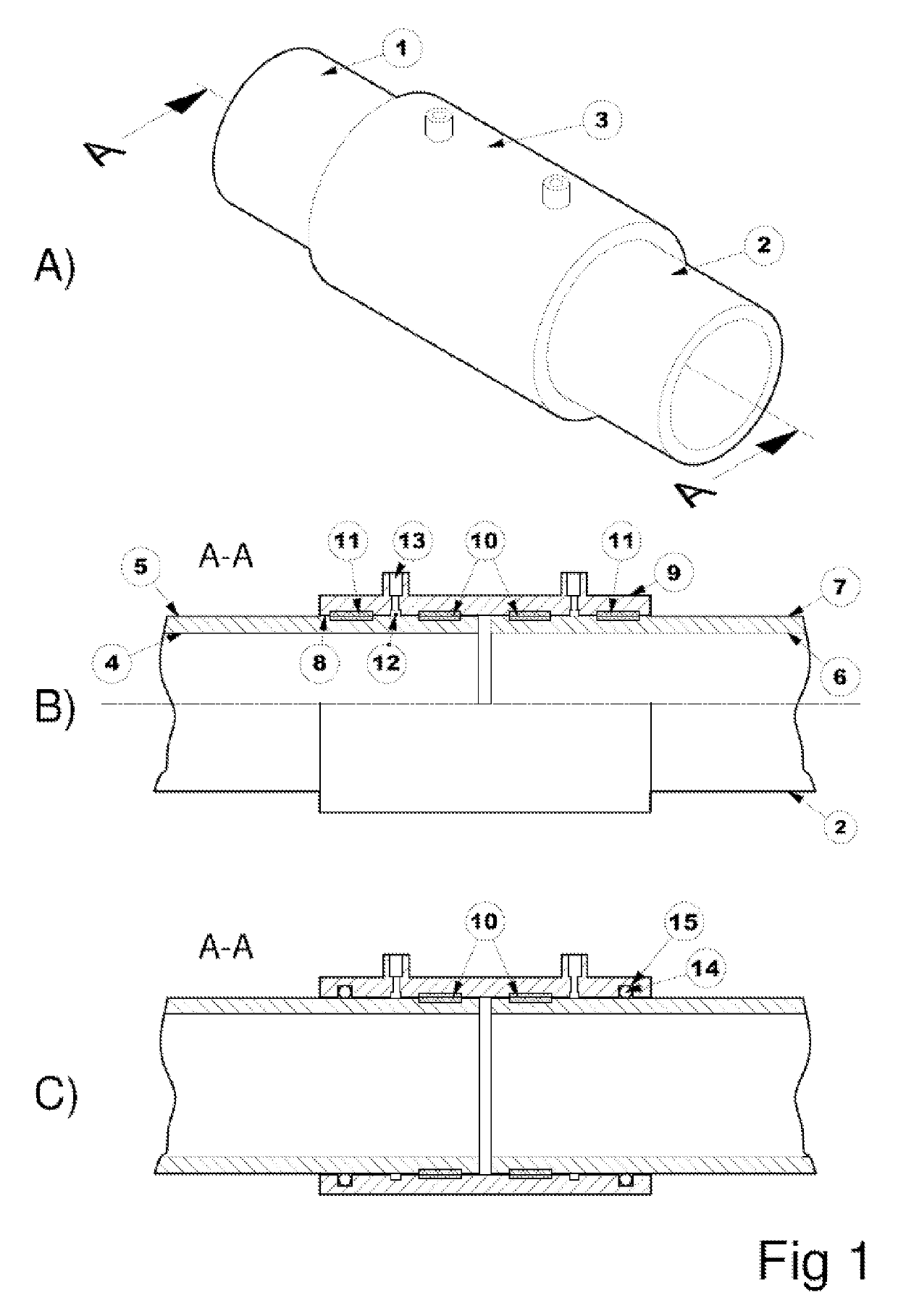

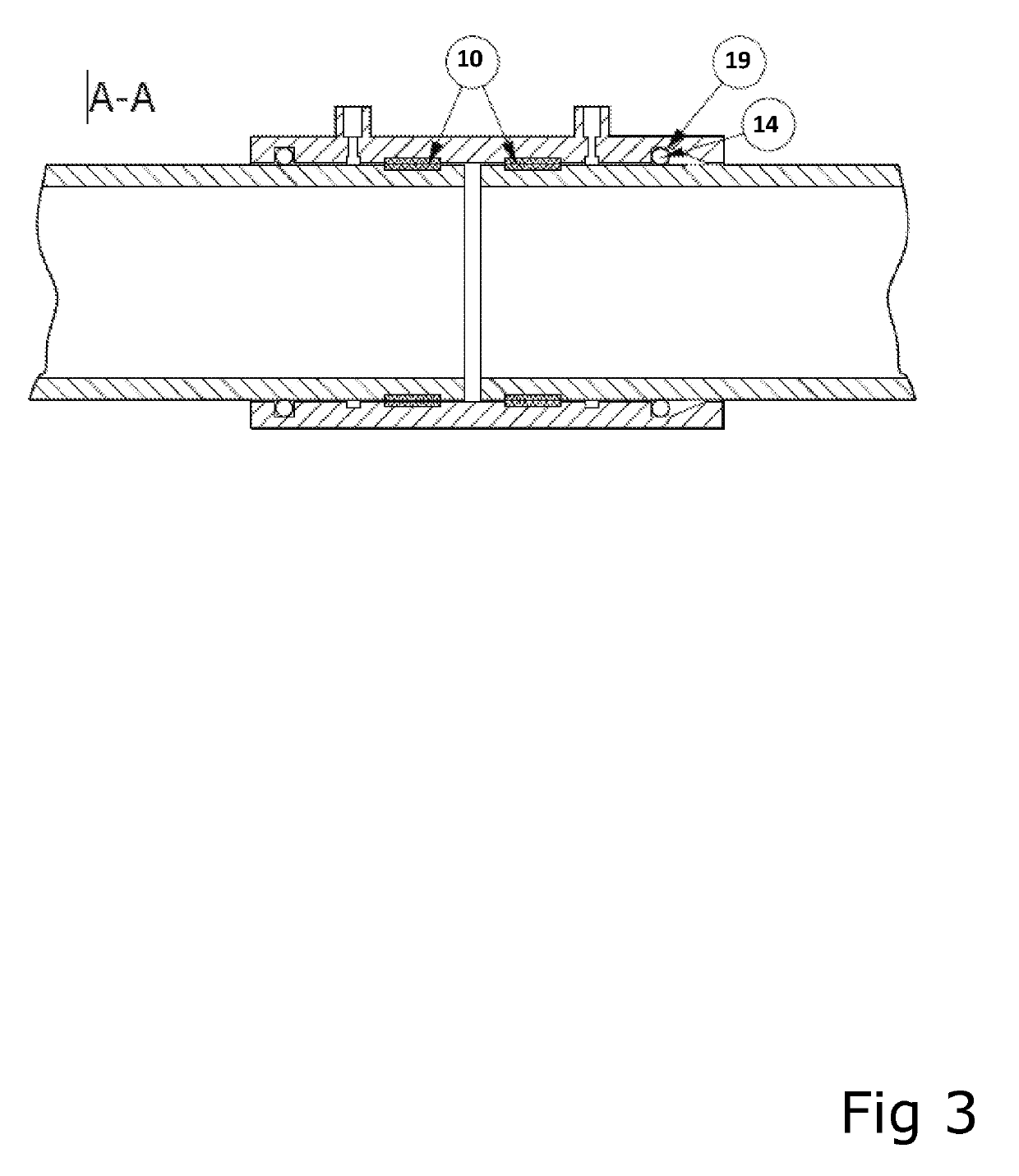

Pipe Fittings Allowing Non-Destructive Pressure Testing of Integrity of Seals

ActiveUS20160186910A1Increase flexibilityNon-destructive testingPipe couplingsFluid-tightness measurementEngineeringPull off test

Fittings to join and tightly seal tubes such as plastic tubes used in but not limited to various plumbing applications. The fittings allow for rigorous and non-destructive tests of the integrity of seals, where the integrity of seals can be readily and quickly tested one by one, as a pipe system is being built. The seals can also be tested again, after installation and completion of the plumbing arrangement. The fitting comprises two pairs of sealing zones, each pair having in between sealing zones a pressure testing chamber with an inlet, which allows for pressurising the chamber and testing the integrity of the adjacent seals. The fittings have a series of cold zones that enhance flexibility and integrity of the fittings.

Owner:PROPER PIPE EHF +1

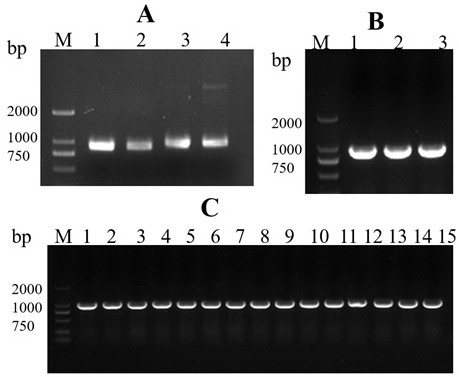

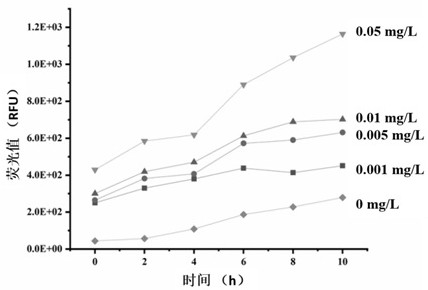

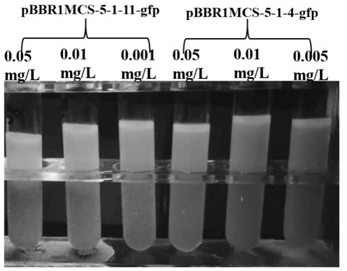

Novel photosynthetic bacteria for detecting explosives as well as preparation method and application of novel photosynthetic bacteria

ActiveCN113373102ARealize detectionRigorous testingBacteriaMicroorganism based processesBiotechnologyLuciferase Gene

The invention provides novel photosynthetic bacteria for detecting explosives as well as a preparation method and application of the novel photosynthetic bacteria. The preparation method of the novel photosynthetic bacteria is simple, an exogenous reporter gene is introduced into rhodopseudomonas palustris, an original biological sensing element in a strain body is used for recognizing explosive molecules, and the detection on the explosive molecules is realized through a signal generated by a reporter gene expression product. The novel photosynthetic bacteria are finally used for preparing a rhodopseudomonas palustris biosensor, and the rhodopseudomonas palustris biosensor contains a promoter gene and a transcriptional regulation protein gene, a green fluorescent protein gene or a luciferase gene. The rhodopseudomonas palustris biosensor is wide in detection range, high in sensitivity, simple and convenient in method, low in cost, high in safety and high in adaptability, is environmentally friendly and has a broad application prospect.

Owner:QINGDAO AGRI UNIV

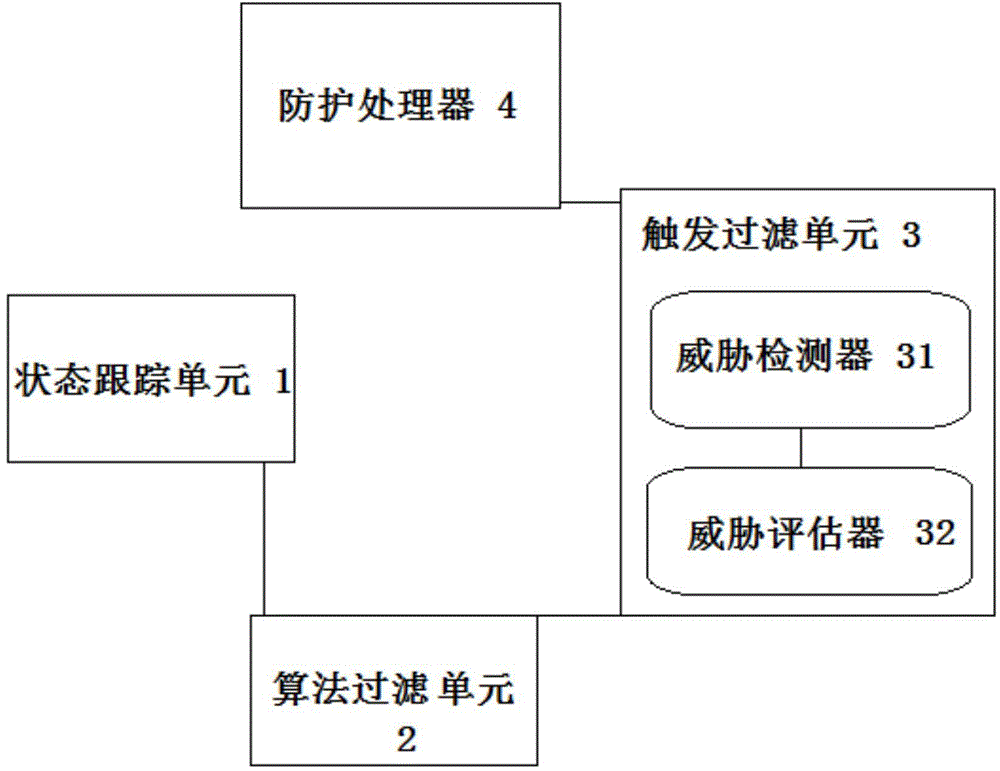

Network attack protective system capable of effectively preventing threats

InactiveCN104579730AHigh precisionRigorous testingData switching networksNetwork attackProtective system

The invention relates to the technical field of network attack protection, in particular to a network attack protective system capable of effectively preventing threats. The system comprises a state tracking unit, an algorithm filter unit, a trigger filter unit and a protective processor, wherein the state tracking unit is connected with the algorithm filter unit; the algorithm filter unit is connected with the trigger filter unit; the trigger filter unit is connected with the protective processor; the trigger filter unit comprises a threat detector and a threat evaluator which are connected. The invention aims to provide the network attack protective system capable of effectively preventing threats, and the network attack protective system is safe, efficient, rigorous in detection and high in accuracy.

Owner:NINGXIA XIANFENG SOFTWARE

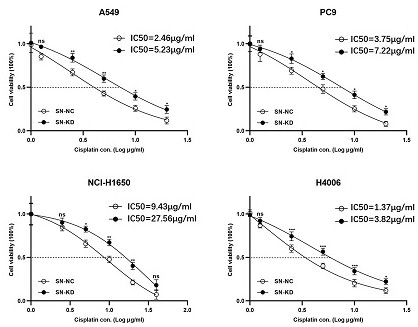

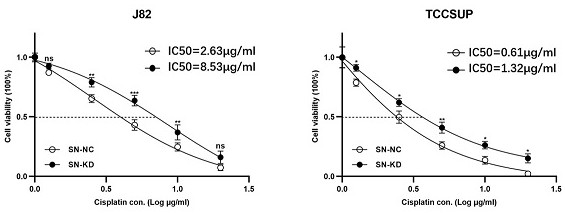

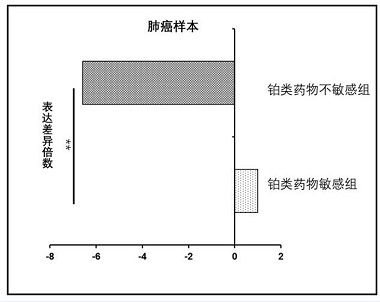

Kit for evaluating curative effect of platinum drugs for patients with lung cancer or bladder cancer and application of kit

ActiveCN114317758AHigh detection sensitivityStrong specificityMicrobiological testing/measurementAgainst vector-borne diseasesTherapeutic effectOncology

The invention relates to the technical field of molecular biology, and particularly discloses application of snoRNA SNORD33 in preparation of a kit and / or a preparation for evaluating curative effects of platinum drugs for patients with lung cancer or bladder cancer. Platinum drugs are common chemotherapeutic drugs for treating lung cancer and bladder cancer patients, however, the expression quantities of the snoRNA SNORD33 in the plasma of the patients are different, so that the curative effects of the patients on the platinum drugs are different, and therefore, the detection of the expression quantity difference of the snoRNA SNORD33 in the plasma can be used for evaluating the curative effects of the platinum drugs of the lung cancer or bladder cancer patients. The invention further provides a kit capable of detecting the expression quantity of the snoRNA SNORD33. The kit comprises a reverse transcription reaction system and a fluorescent quantitative PCR reaction system. The kit is rapid and convenient in detection and high in accuracy, and can realize platinum drug curative effect evaluation of patients with lung cancer or bladder cancer. The method can assist doctors in evaluating and judging the curative effect of platinum drugs for patients with lung cancer or bladder cancer, provides valuable decision basis and reference information for the doctors to select proper treatment schemes, is beneficial to improving the treatment effect and life quality of the patients with lung cancer or bladder cancer, and has very important clinical value.

Owner:润安医学科技(苏州)有限公司

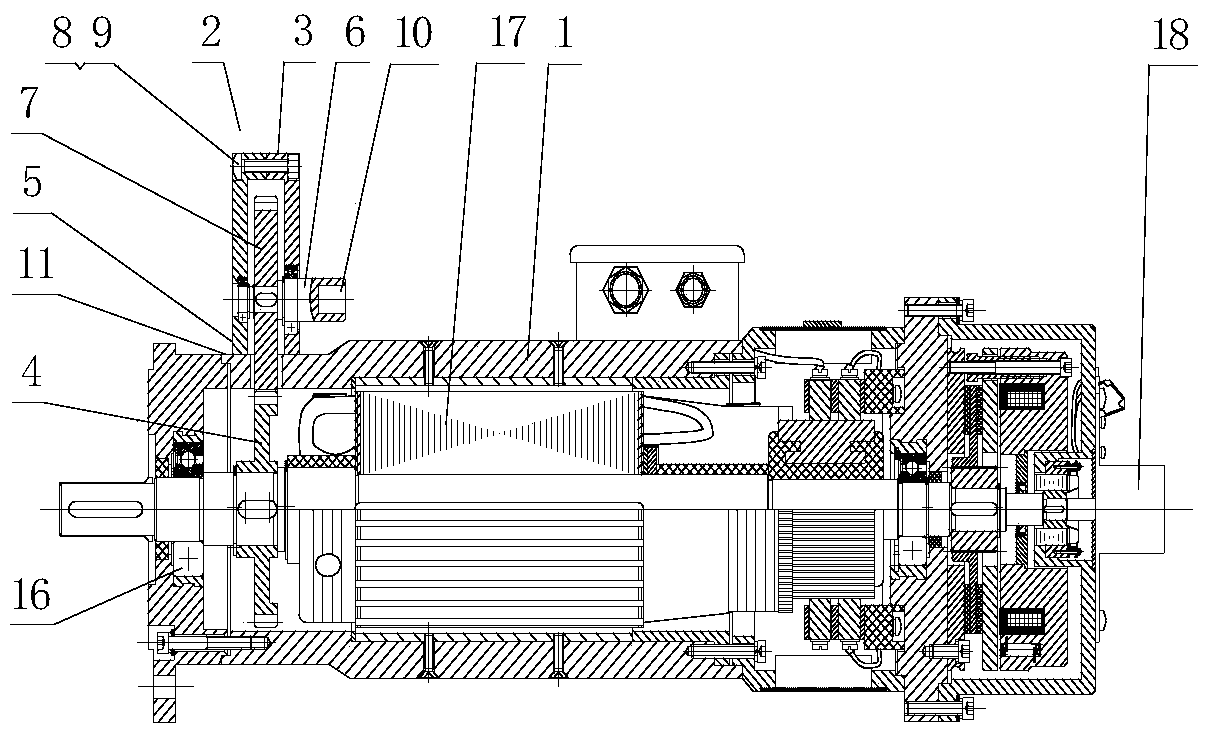

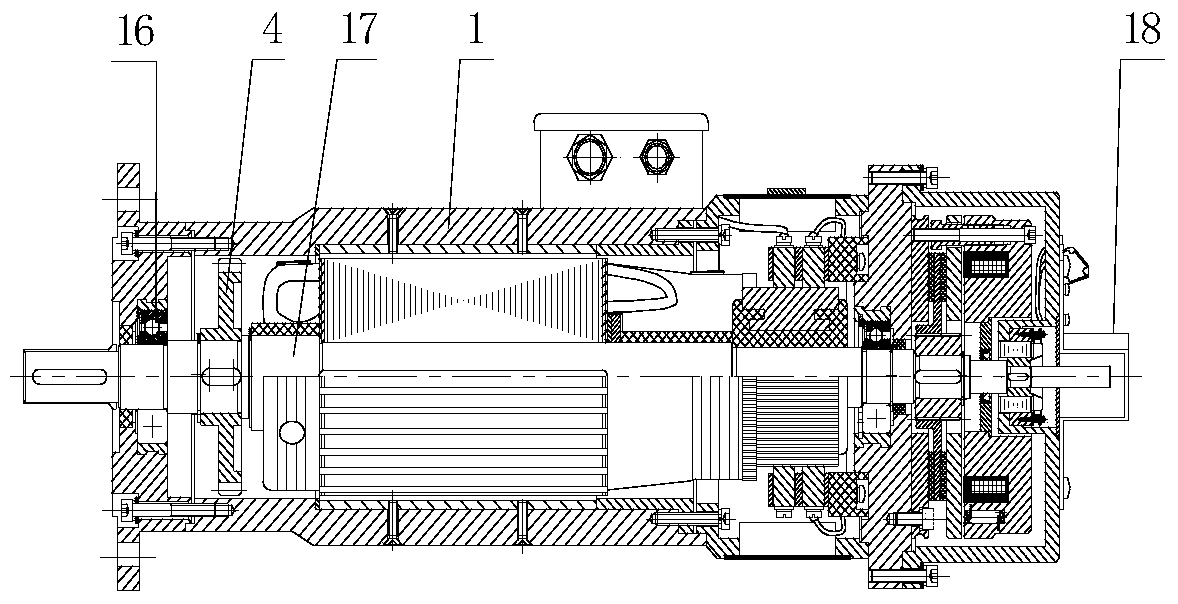

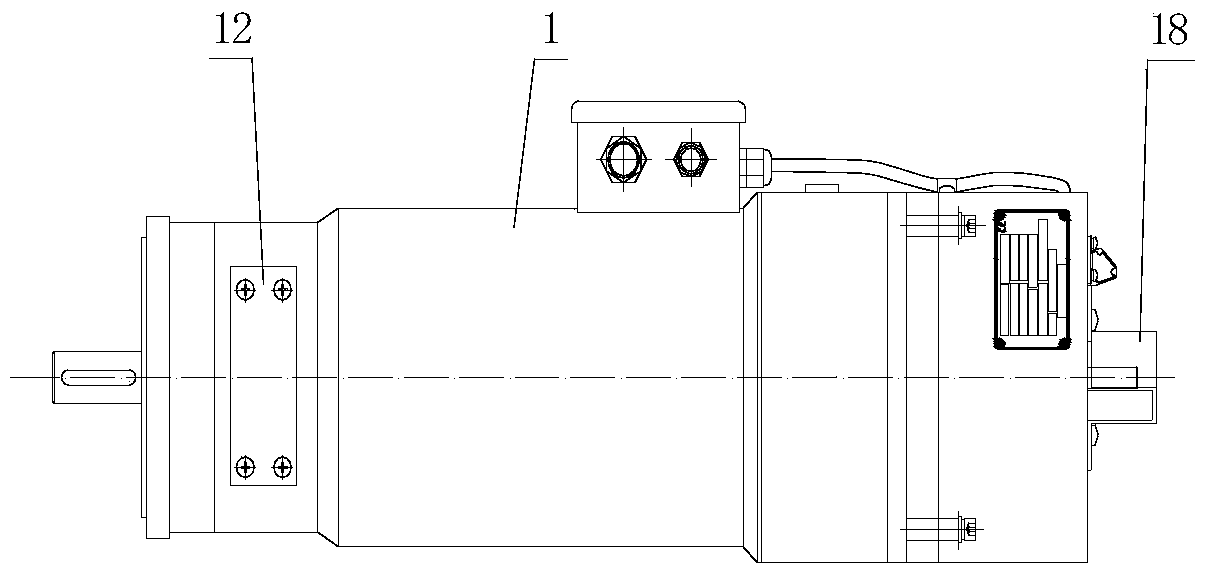

An online motor braking torque detector and its detection method

InactiveCN103759877BSolve the traditional problem that the safe braking torque cannot be detectedSimple structureApparatus for force/torque/work measurementStructural associationBrake torqueButt joint

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

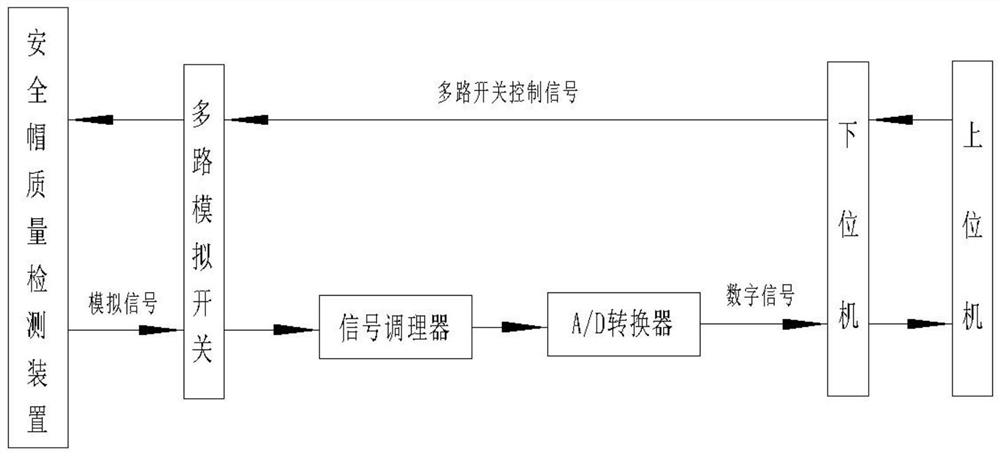

Safety helmet quality detection and construction safety evaluation system

PendingCN112798420AComprehensive collection of dataRigorous testingMaterial strength using tensile/compressive forcesAutomotive engineeringSignal Conditioner

The invention belongs to the technical field of safety helmet quality detection and provides a safety helmet quality detection and construction safety evaluation system. The system comprises a safety helmet quality detection device, a multi-channel analog switch, a signal conditioner, an A / D converter, a lower computer and an upper computer, wherein the safety helmet quality detection device is connected with the multi-channel analog switch, the multi-channel analog switch is connected with the signal conditioner, the signal conditioner is connected with the A / D converter, the A / D converter is connected with the lower computer, and the lower computer is connected with the upper computer, so problems that stress data acquired during safety helmet quality detection is single and incomplete, and stress conditions of the head in all directions of a person wearing a safety helmet in real life cannot be comprehensively simulated and evaluated when the person is hit, and a specific detection device is in a lacking state are solved. The system is advantaged in that data collection is comprehensive, safety helmet quality detection is more rigorous, and safety helmet quality qualification evaluation is more accurate.

Owner:TIANJIN DWG FORMWORK & SCAFFOLD ENG CO LTD

Pipe fittings allowing non-destructive pressure testing of integrity of seals

InactiveUS10274121B2Easy to testIncrease pressureMeasurement of fluid loss/gain ratePipe couplingsNon destructivePipe fitting

Fittings to join and tightly seal tubes such as plastic tubes used in but not limited to various plumbing applications. The fittings allow for rigorous and non-destructive tests of the integrity of seals, where the integrity of seals can be readily and quickly tested one by one, as a pipe system is being built. The seals can also be tested again, after installation and completion of the plumbing arrangement. The fitting comprises two pairs of sealing zones, each pair having in between sealing zones a pressure testing chamber with an inlet, which allows for pressurizing the chamber and testing the integrity of the adjacent seals. The fittings have a series of cold zones that enhance flexibility and integrity of the fittings.

Owner:PROPER PIPE EHF +1

Board-level radio frequency signal test system, method and device without radio frequency test socket

ActiveCN112003657BRigorous testingIngenious structureTransmitters monitoringReceivers monitoringElectrical connectionRadio frequency signal

The board-level radio frequency signal testing system, method and device proposed by the present invention without radio frequency test socket are used to test radio frequency signals of radio frequency circuits; including radio frequency test probes, tuning modules and test instrument modules, one end of radio frequency test probes and radio frequency The antenna shrapnel of the circuit is connected, and the other end is connected to the tuning module; the tuning module is connected to the test instrument module, and the tuning module adjusts the matching impedance according to the return loss; the matching impedance matches the impedance of the radio frequency circuit; The shrapnel of the antenna is electrically connected, and then the size of the matching impedance is adjusted through the tuning module, and the size of the return loss can be used to judge whether the matching impedance is matched in place until the matching impedance matches the impedance in the radio frequency circuit, so that it can be directly passed through the antenna. The purpose of the shrapnel for RF signal testing; the test results are rigorous and the structure is ingenious; the design space and production cost of the RF test socket in the RF circuit are saved.

Owner:深圳合一测试科技有限公司

Plank surface flatness detection device for furniture processing

InactiveCN112461106AEasy to fill jobsLabor savingMechanical roughness/irregularity measurementsSpray nozzleWood plank

The invention belongs to the technical field of furniture processing, particularly relates to a plank surface flatness detection device for furniture processing. The invention aims to solve the problems that errors are large and uneven positions cannot be marked in actual operation in the prior art. According to a technial scheme in the invention, the plank surface flatness detection device comprises a workbench, wherein supporting plates are fixed to the two sides of the outer wall of the top of the workbench; a cover plate is fixed to the outer walls of the tops of the supporting plates; a sliding groove is formed in the middle of the cover plate; a communicating pipe slides in the sliding groove; a material spraying nozzle is fixed to one end of the communicating pipe; a sliding ball isembedded in the material spraying nozzle; a bottom plate is arranged on the outer wall of the top of the sliding ball; sensitive spring columns are fixed to the two sides of the outer wall of the topof the bottom plate; a top plate is fixed to the outer walls of the tops of the two sensitive spring columns; and a communicating opening is formed in the top of the material spraying nozzle. According to the invention, a sunken part can be detected through rolling of the sliding ball on a plank, then the top plate does not keep a conduction nozzle sealed under the action of pressure, and then apowder marker falls down to mark the sunken part.

Owner:李家臣

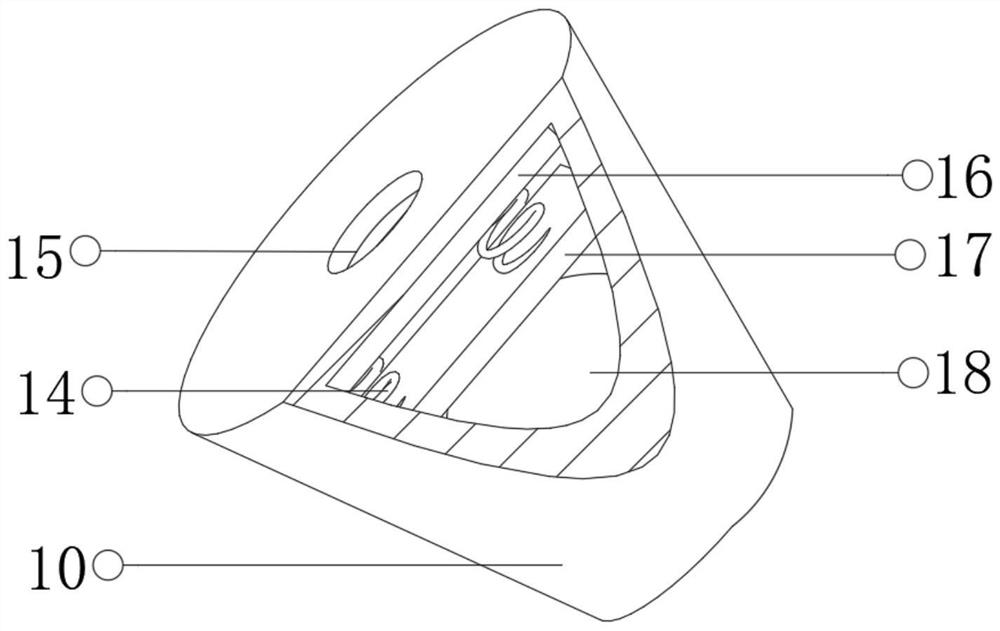

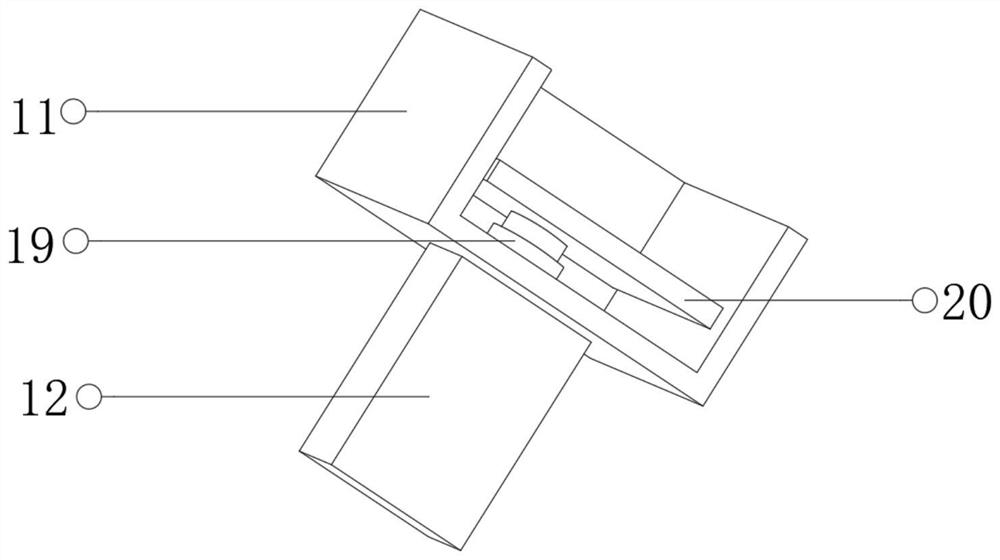

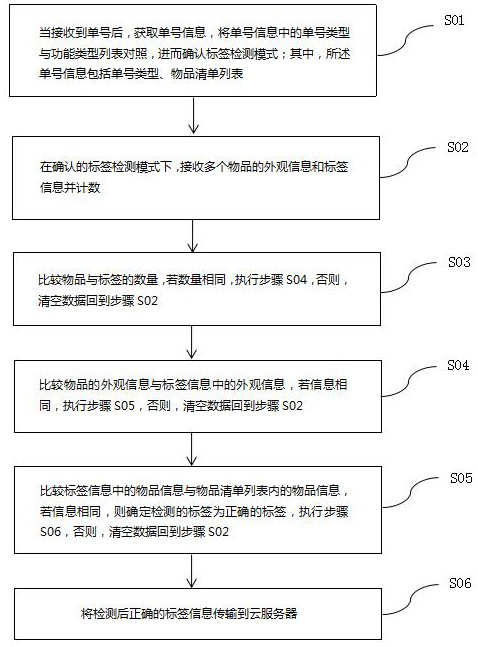

PDA-based intelligent label detection method and device

InactiveCN111783908ARigorous testingImprove accuracyCo-operative working arrangementsEngineeringInformation transfer

The invention discloses a PDA-based intelligent label detection method and device, and relates to the technical field of detection. An intelligent label detection method based on a PDA is applied to aPDA device terminal. The method comprises the following steps: S01, after receiving an order number, acquiring order number information, comparing an order number type in the order number informationwith a function type list, and further confirming a label detection mode; step S02, in the confirmed label detection mode, receiving appearance information and label information of a plurality of articles and counting; s03, comparing the number of the articles with the number of the labels; s04, comparing the appearance information of the article with the appearance information in the label information; s05, comparing the article information in the label information with the article information in the article list; and step S06, transmitting the detected correct label information to a cloud server. The PDA-based intelligent label detection equipment is used for label detection. The invention provides the PDA-based intelligent label detection method and the PDA-based intelligent label detection equipment which are used for automatically and intelligently identifying whether label information is correct or not.

Owner:湖州朗讯信息科技有限公司

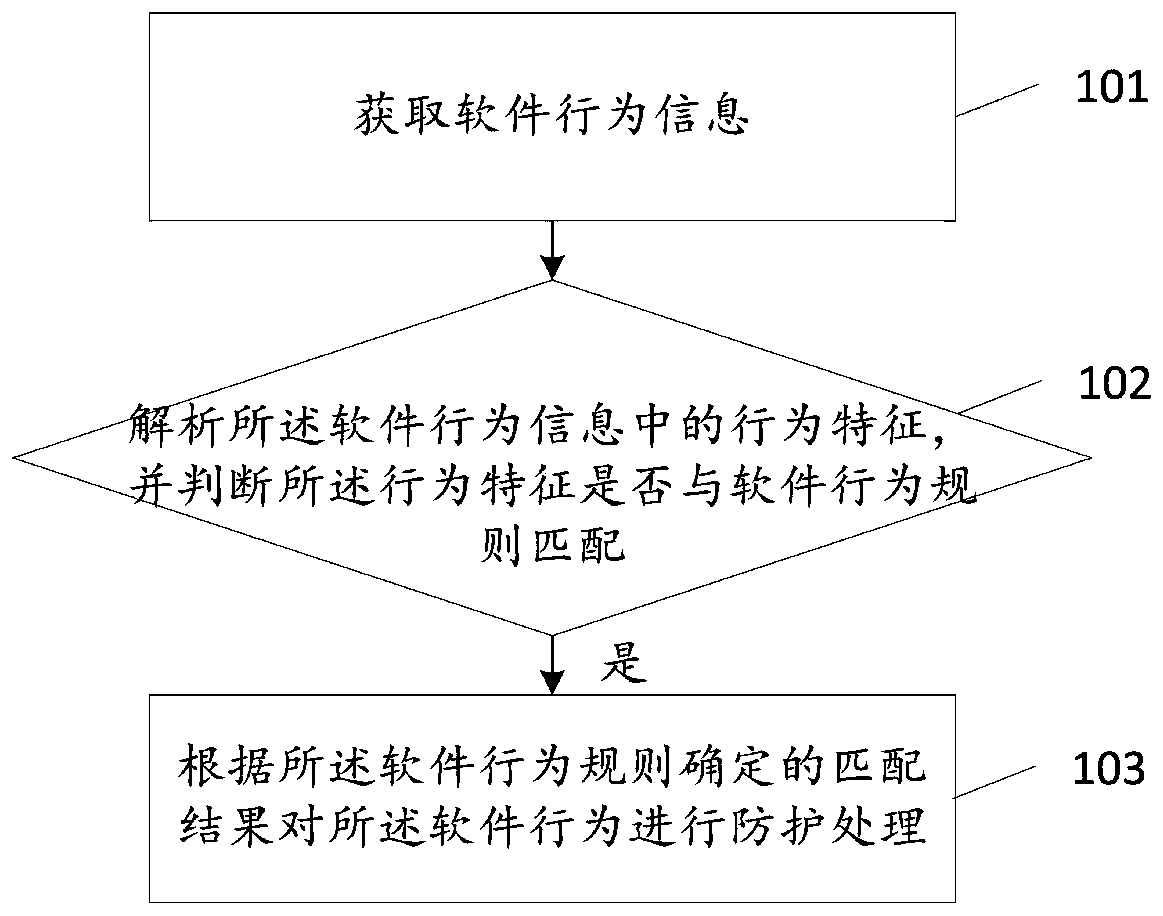

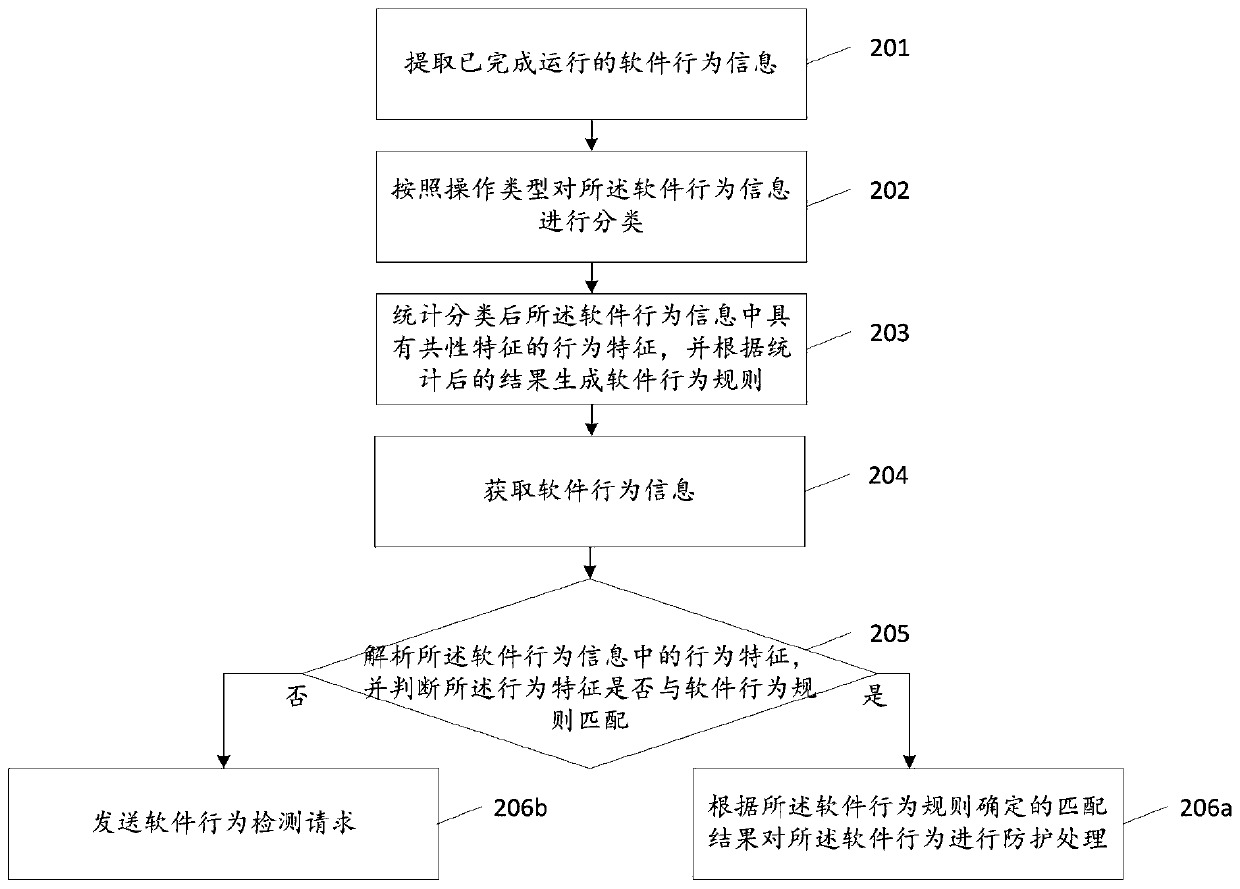

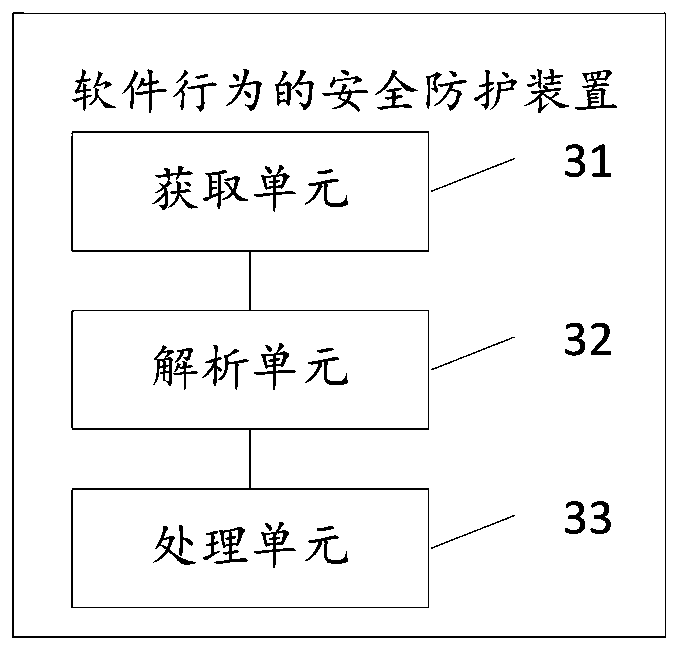

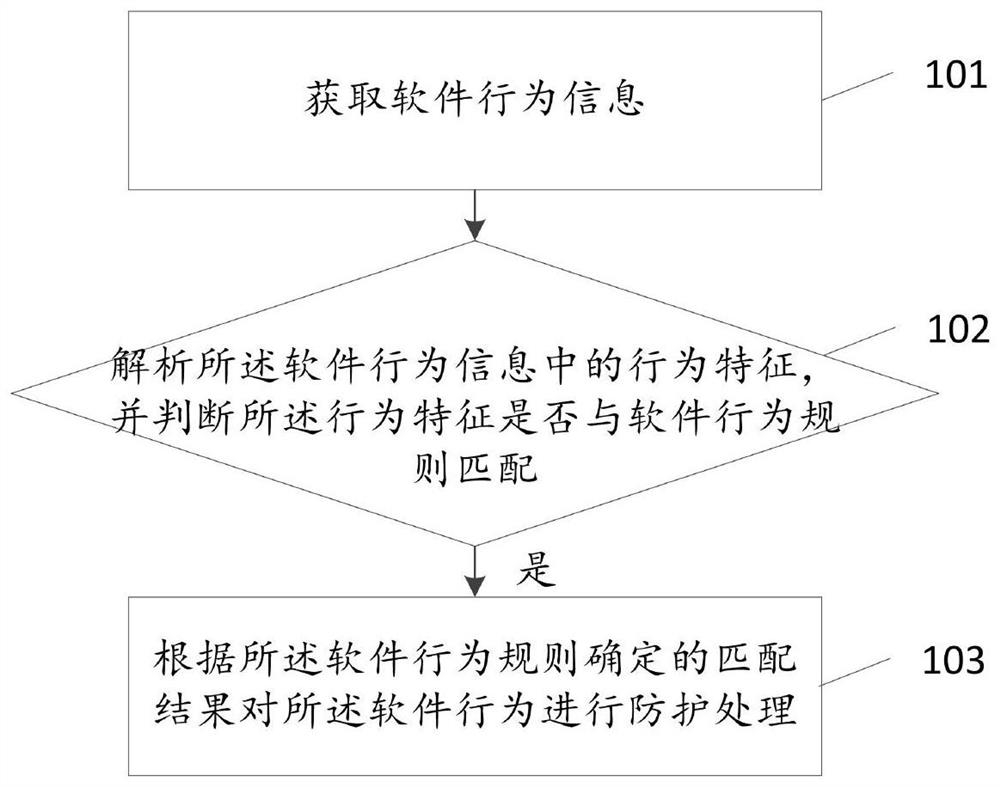

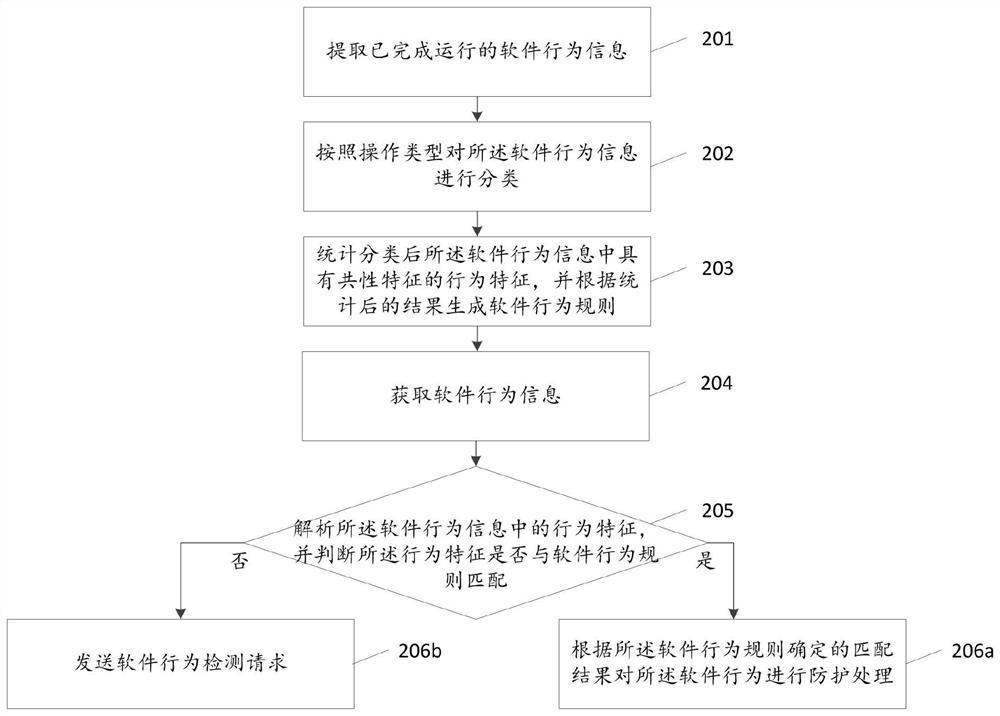

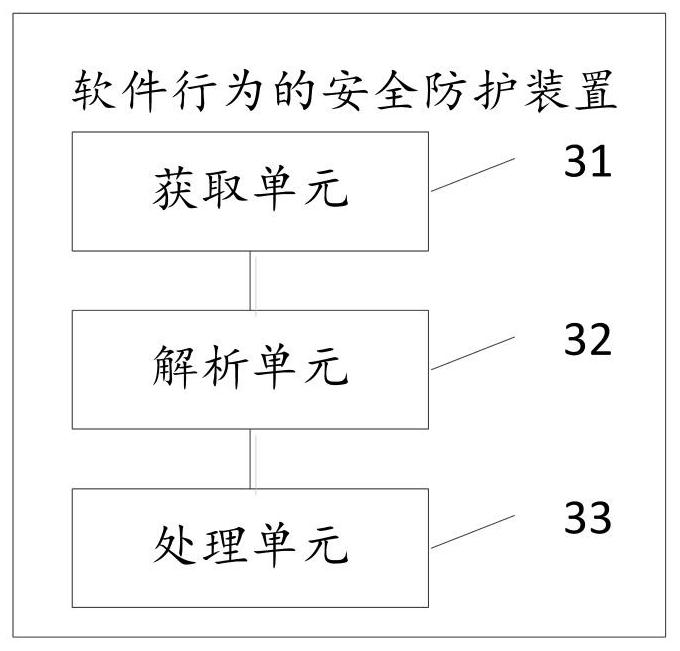

Software behavior safety protection method and device, storage medium and computer equipment

ActiveCN109800581ARigorous testingImprove protection efficiencyPlatform integrity maintainanceInformation technologyComputer equipment

The invention discloses a software behavior safety protection method and device, a storage medium and computer equipment, relates to the technical field of communication and information, and mainly aims to solve the problem that safety protection of software behaviors only aims at safety detection of different authority distributions in a software process. The method comprises the steps that software behavior information is acquired, and the software behavior information is information of behaviors generated after software runs on an application platform; Behavior characteristics in the software behavior information are analyzed, whether the behavior characteristics are matched with software behavior rules or not is judged, and the software behavior rules are rules used for judging whethersoftware behaviors corresponding to the behavior characteristics are safe behaviors or not; And if the behavior characteristics are matched with a software behavior rule, performing protection processing on the software behavior according to a matching result determined by the software behavior rule.

Owner:QI AN XIN SECURITY TECH ZHUHAI CO LTD +1

A non-destructive testing method for tunnel lining based on audio frequency analysis

ActiveCN110045016BTo achieve the effect of non-destructive testingEliminate distractionsAnalysing solids using sonic/ultrasonic/infrasonic wavesRoad engineeringEngineering

Owner:四川升拓检测技术股份有限公司

A smart wristband with strong battery life for medical treatment

ActiveCN109744665BImprove battery lifePracticalDiagnostic recording/measuringBraceletsCircular discComputer science

The invention relates to a smart wristband with strong battery life for medical treatment, comprising a main body, a display screen and a ring belt, the display screen is arranged on the main body, the shape of the display screen is a disc, and the ring belt is fixed On the main body, a detection mechanism and a running mechanism are arranged in the main body, and the running mechanism includes a moving block, a rack, a first gear, a second gear, a rotating shaft, a generator and two support assemblies, and the support assembly Comprising a transmission block, a first slider, a touch sensor, two light rods and two first springs, the detection mechanism includes at least two detection components, and the smart wristband with strong endurance for medical treatment is realized by the endurance mechanism Not only that, but also realize the function of detecting whether the user has fallen through the detection mechanism.

Owner:山东鑫年信息科技有限公司

Use of the product for detecting the methylation site of the ndrg4 gene in the preparation of a product for the early detection of colorectal cancer

ActiveCN108676878BAccurate detectionHigh sensitivityMicrobiological testing/measurementOncologyPromoter

The invention discloses a method for early detection on a colorectal cancer on the basis of a NDRG4 gene methylation sequence. The auxiliary diagnosis is performed on the early colorectal cancer through detecting whether a section of methylation sequence of a NDRG4 gene promoter region is methylated or not; the method comprises the following steps: extracting DNA from tissue and fecal samples, treating with hydrosulfite, then performing real-time quantitative PCR determination and judging a methylation level through calculating whether an amplified Ct ratio difference value between a target gene NDRG4 and an internal reference gene B2M is within a decision critical value or not. The method is noninvasive and can be used for the auxiliary diagnosis of the early colorectal cancer.

Owner:HANGZHOU NEW HORIZON HEALTH TECH CO LTD

Safety protection method and device for software behavior, storage medium, computer equipment

ActiveCN109800581BRigorous testingImprove protection efficiencyPlatform integrity maintainanceTheoretical computer scienceSoftware engineering

Owner:QI AN XIN SECURITY TECH ZHUHAI CO LTD +1

Fixtures for mechanical load testing of photovoltaic modules

ActiveCN103439183BRigorous testingImprove mechanical propertiesMaterial strength using tensile/compressive forcesEngineeringMechanical load

The invention discloses a clamping tool for testing the mechanical load of a photovoltaic module. The clamping tool comprises a pair of long cushion blocks arranged in parallel, wherein each long cushion block is provided with at least two clamps, the clamps are connected through bolts to fixedly connect an aluminum alloy guide rail onto the inner sides of the long cushion blocks, the length of the aluminum alloy guide rail is not less than that of each long side frame of the photovoltaic module, a slide slot for accommodating and clamping each long side frame of the photovoltaic module is arranged on the inner side of the aluminum alloy guide rail, the two slide slots of the aluminum alloy guide rail arranged on the two long cushion blocks are located at the same horizontal heights, so that the clamped photovoltaic module is guaranteed to be placed horizontally. According to the clamping tool provided by the invention, the reliability of a test result is improved, the mechanical load test is more precise, and the comprehensive mechanical performance of the photovoltaic module passing the test is better.

Owner:赣州爱康光电科技有限公司

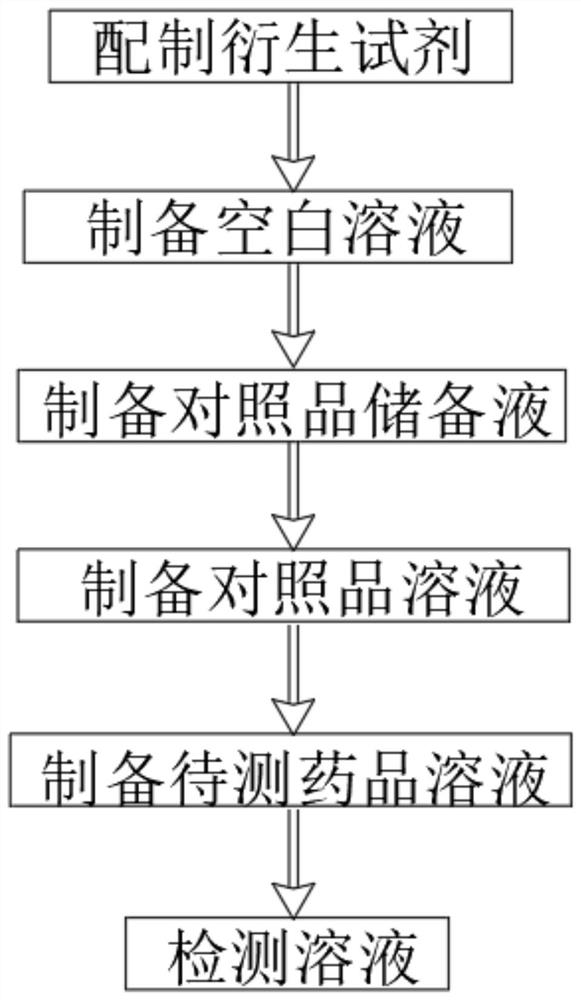

Method for detecting residual dimethyl sulfate in medicine by liquid chromatography-mass spectrometry

InactiveCN112924577AEasy to observe and compare test resultsGood peak shapeComponent separationMass Spectrometry-Mass SpectrometrySolvent

The invention relates to the technical field of dimethyl sulfate detection, and discloses a method for detecting dimethyl sulfate residues in a medicine by liquid chromatography-mass spectrometry, which comprises the following steps: S1, preparing a derivative solution, taking 10-30mg of dimethyl fumarate powder, and preparing a sample derivative solution by using a secondary amine-containing acetonitrile solution as a derivative agent, wherein the mass ratio of the dimethyl fumarate to the acetonitrile solution is (1-5):(2-8); S2, preparing a blank solution, weighing the derivative solution in the step S1 with the volume of 20-80 mg, and adding deionized water for dilution to obtain the blank solution; and S3, preparing a control stock solution. According to the method, dimethyl sulfate is accurately detected through the derivatization reaction of the acetonitrile solvent, so that the detected ion peak is good in peak shape, detection personnel can conveniently observe and compare the detection result, and meanwhile, a worker can conveniently compare data obtained through the reaction by preparing the reference substance solution and the to-be-detected solution, and therefore, the detected data is more persuasive.

Owner:ZUNYI NO 1 PEOPLES HOSPITAL

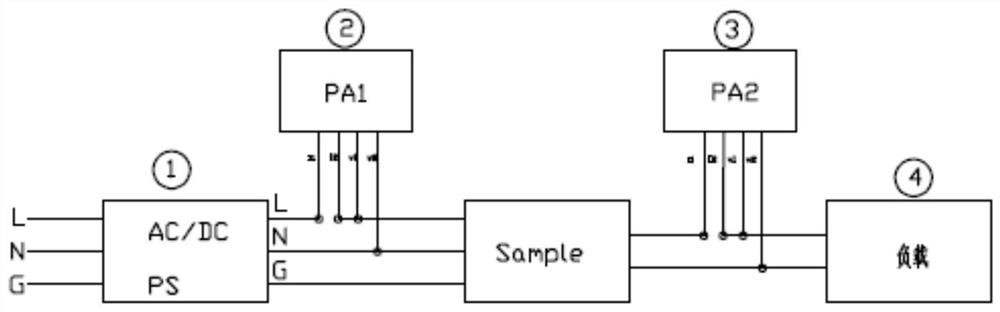

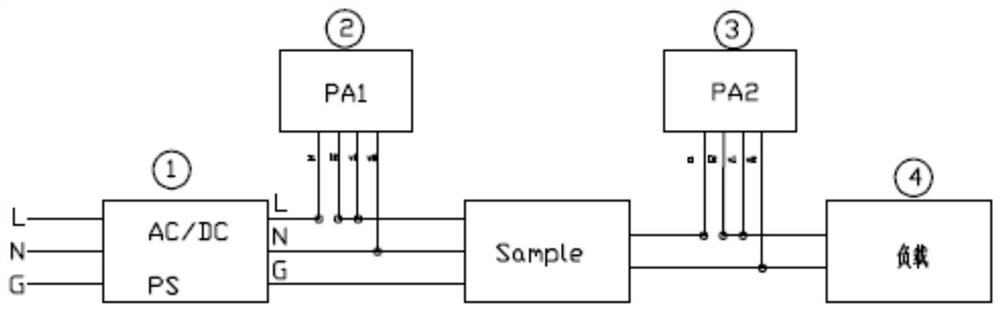

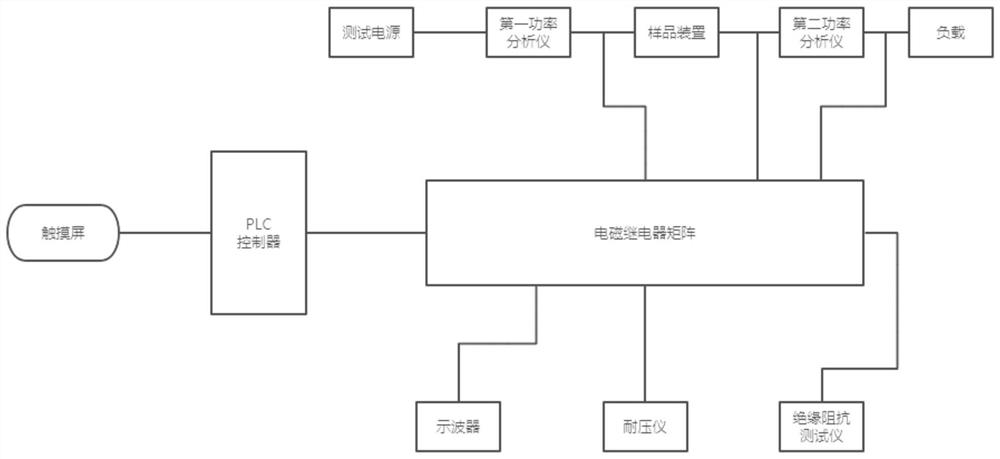

Automatic test system for lamp safety regulations

The invention discloses an automatic test system for lamp safety regulations. The system comprises an input / output test unit, an input test unit, a harmonic distortion test unit, an output load test unit, a full-load output current test unit, a leakage current test unit, an output current and power test unit, a withstand voltage test unit, an impedance test unit, a maximum output voltage test unit, a maximum input voltage test unit and a capacitor discharge test unit; a PLC is used for acquiring a user instruction and controlling each test unit to test according to the program; a touch screenis used for communicating with the PLC controller, and acquiring a user instruction through the configuration picture, so that the PLC controller enables the corresponding test unit to work and feedsback the control state of the PLC controller on the test unit. According to the invention, the most common 12 detections can be carried out in sequence, the manual operation is replaced to the greatest extent, the efficiency is improved, the detection process is rigorous, the data is real, the efficiency can be improved by about 20 times, the test efficiency is high, and the method is suitable forpopularization.

Owner:吉志华

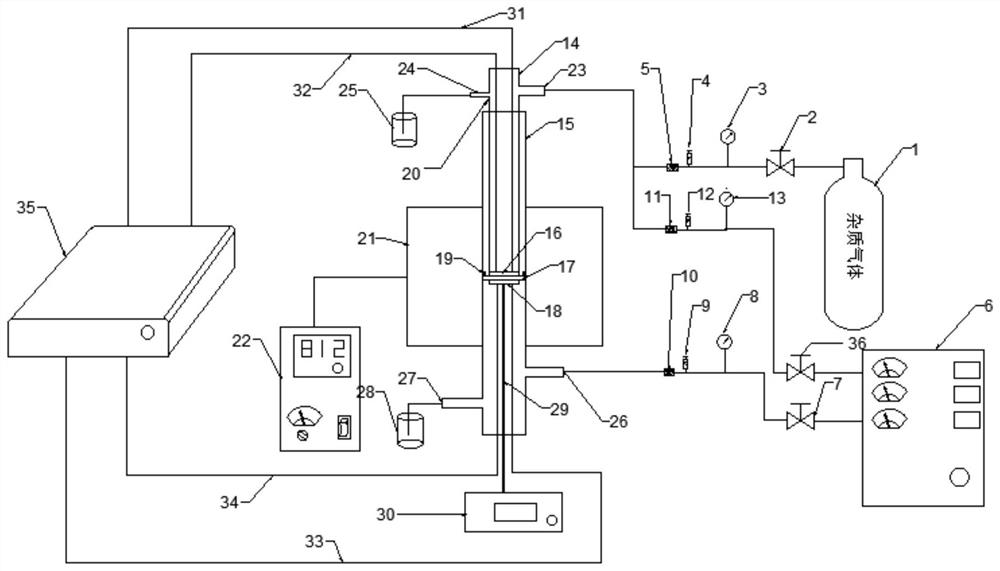

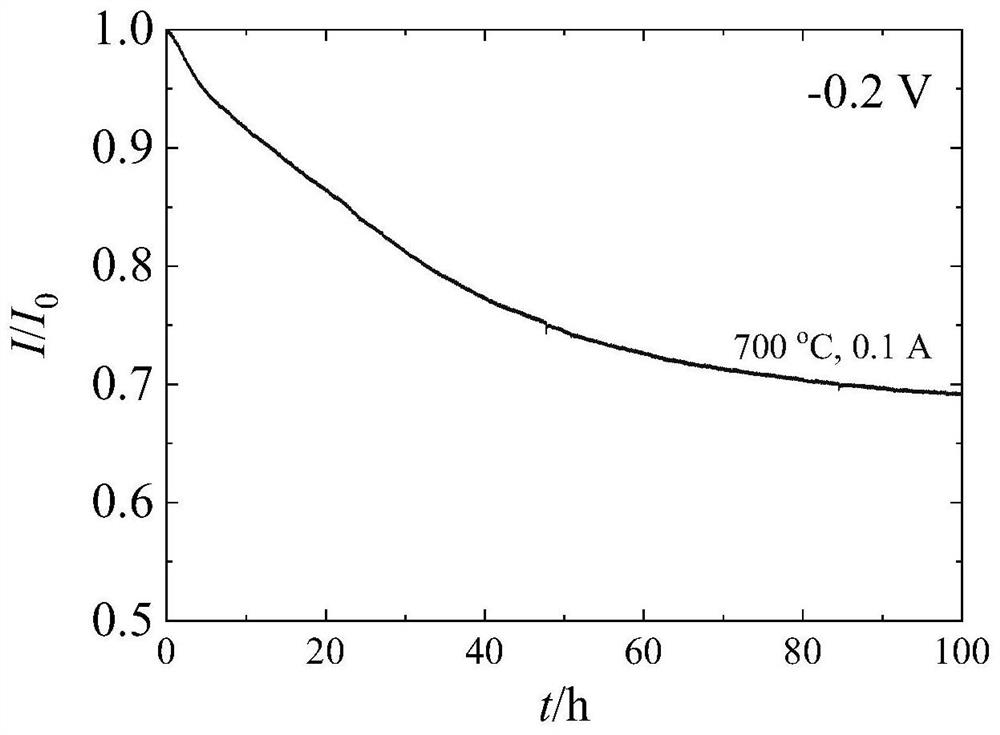

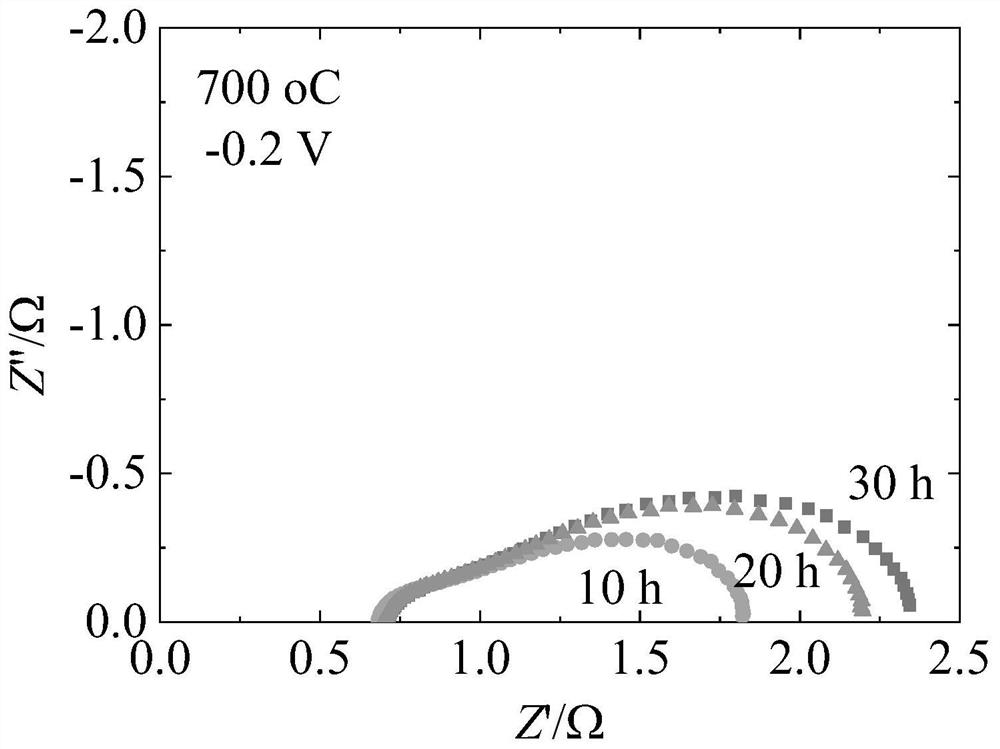

Integrated evaluation device and method for gas impurity poisoning of fuel cell material

PendingCN113049653AGuaranteed air tightnessEnsure safetyMaterial electrochemical variablesElectrical batteryButton battery

The invention discloses an integrated evaluation device and method for gas impurity poisoning of a fuel cell material. The device mainly comprises a gas pipeline system composed of a nitrogen-hydrogen-air all-in-one machine, a steel cylinder, a pressure gauge, a mass flow meter, a ball valve and a steel pipe, a resistance wire furnace, a temperature control system composed of a temperature controller and a thermocouple thermodetector, and a performance test system composed of a glass ring, an alumina tube, a lead and an electrochemical workstation. The alumina tube is used for fixing a button cell sample needing to be tested, different atmosphere environments are provided through the gas pipeline system, the temperature in the alumina tube is monitored in real time through the temperature control system, errors are avoided, and the influence of gas impurity poisoning on a cell material is evaluated according to test data of the electrochemical workstation. The core characteristic of the invention is that: the three systems are integrated, the comprehensive performance is excellent, and the test efficiency and the data accuracy are greatly improved.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com