Fixtures for mechanical load testing of photovoltaic modules

A photovoltaic module and mechanical load technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of unacceptable test results, machining accuracy errors, different distances, etc., to achieve test results. The results are reliable, the mechanical load test is rigorous, and the comprehensive mechanical properties are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

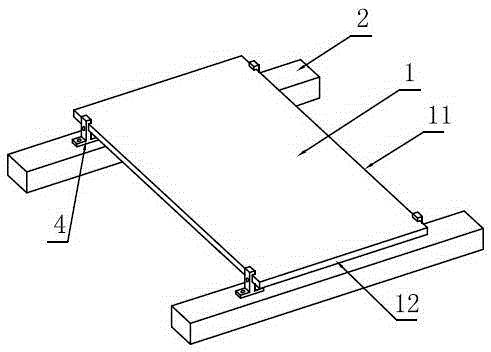

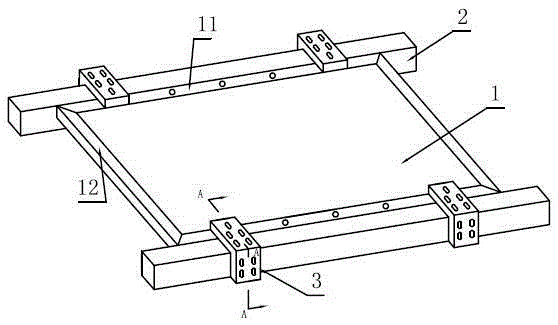

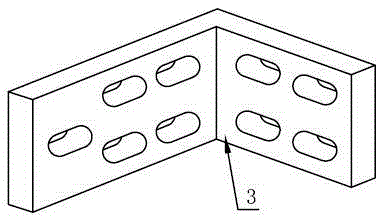

[0012] Such as figure 2 , image 3 , Figure 4 As shown, the clamping tool for mechanical load testing of photovoltaic modules in this embodiment includes: a pair of long cushion blocks 2 arranged parallel to each other, and at least two clamps 3 are provided on each long cushion block 2. 3 The aluminum alloy guide rail 5 is fixedly connected to the inner side of the long spacer block 2 by bolt connection. The length of the aluminum alloy guide rail 5 is not less than the length of the photovoltaic module long frame 11, and the aluminum alloy guide rail 5 is provided on the inner side to accommodate and clamp the photovoltaic module 1 The sliding groove of the long frame 11, the two sliding grooves of the aluminum alloy guide rail 5 arranged on the two long spacers 2 are located at the same level, so as to ensure that the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com