Safety helmet quality detection and construction safety evaluation system

A safety evaluation and safety helmet technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problems of incompleteness, single force data, lack of detection devices, etc., to achieve the quality of safety helmets Accurate qualification assessment, comprehensive data collection, and rigorous testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

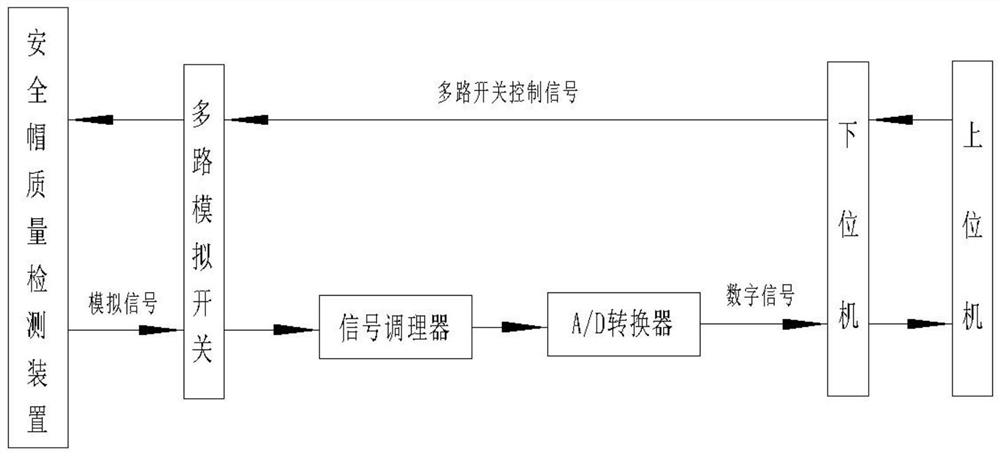

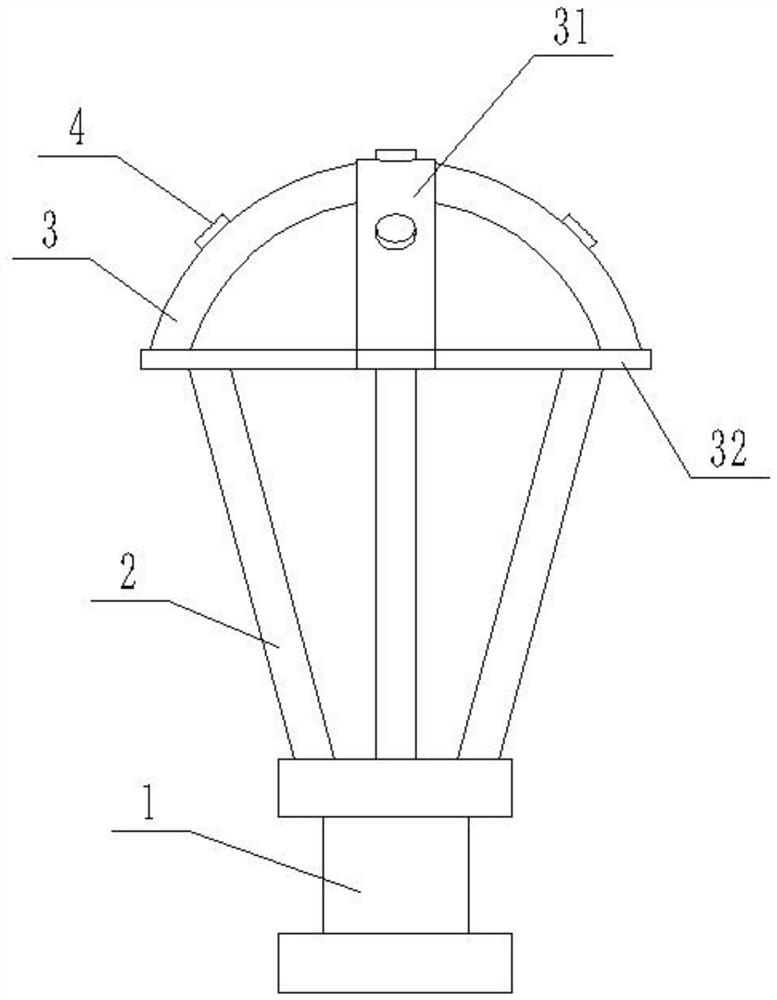

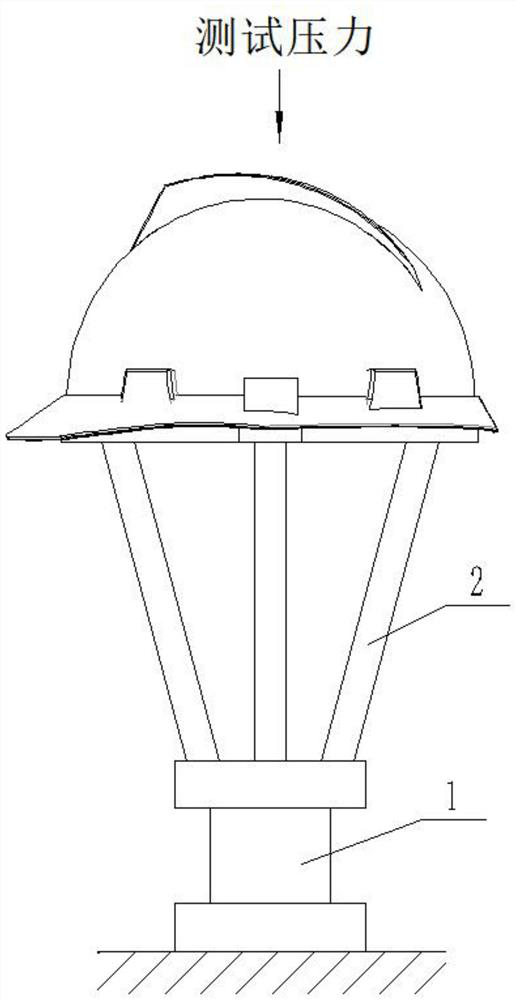

[0026] The invention provides a safety helmet quality inspection and construction safety evaluation system, comprising: a safety helmet quality inspection device, a multi-channel analog switch, a signal conditioner, an A / D converter, a lower computer and an upper computer, the safety helmet quality inspection device Connect with multi-channel analog switch, connect multi-channel analog switch with signal conditioner, connect signal conditioner with A / D converter, connect A / D converter with lower computer, connect lower computer with upper computer, safety helmet quality inspection device The collected pressure analog signal is transmitted to the signal conditioner through a multi-channel analog switch, and the pressure analog signal is processed by the signal conditioner through amplification, filtering, linearization compensation, isolation, protection, etc., and then transferred to the A / D converter for acceptance. The A / D converter converts the pressure analog signal into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com