Plank surface flatness detection device for furniture processing

A technology of surface smoothness and detection device, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of unevenness marks, large errors, etc., and achieve high accuracy, comprehensive detection, and reduce manual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

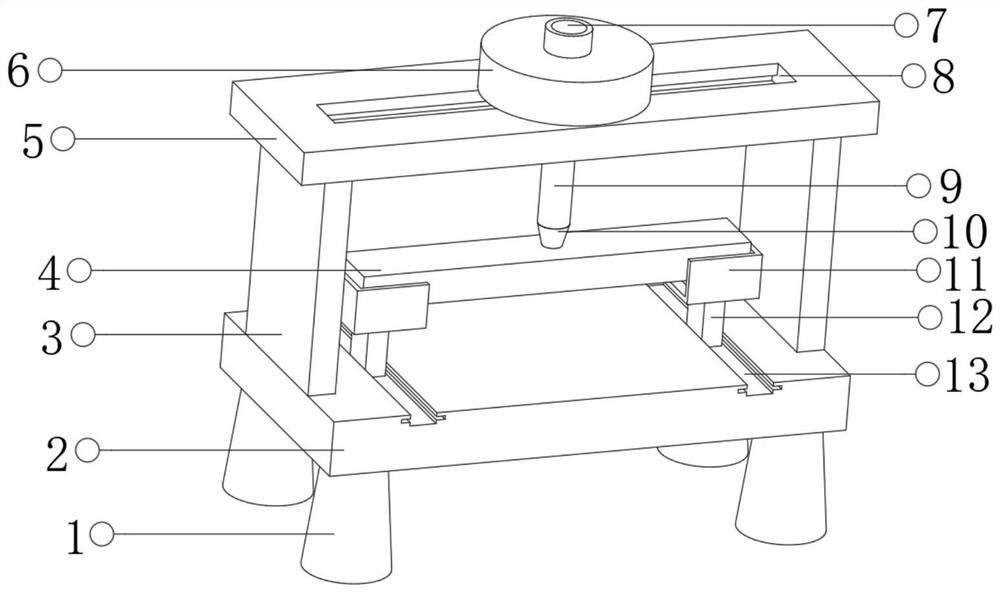

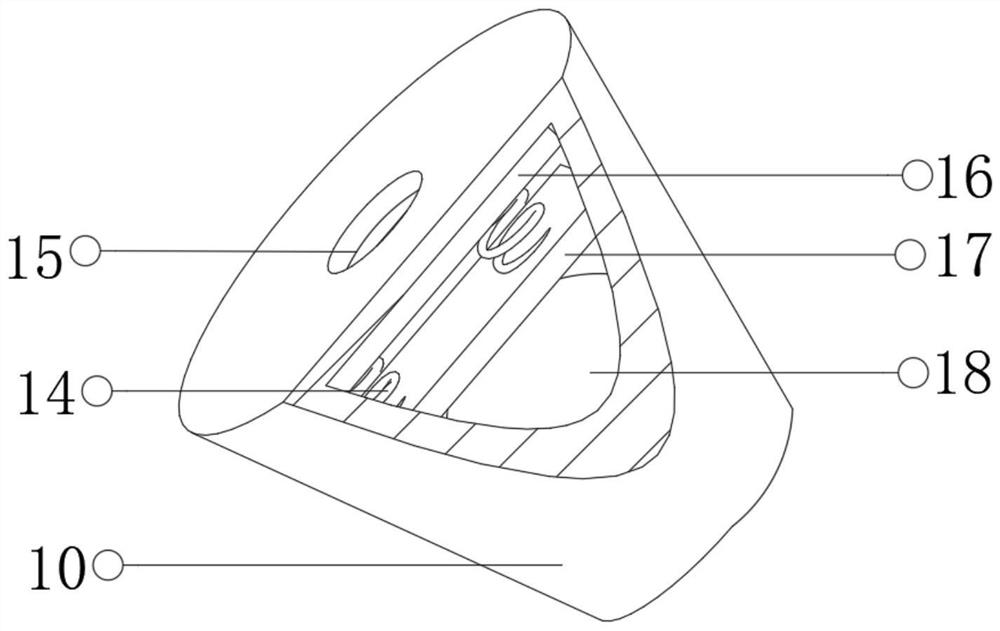

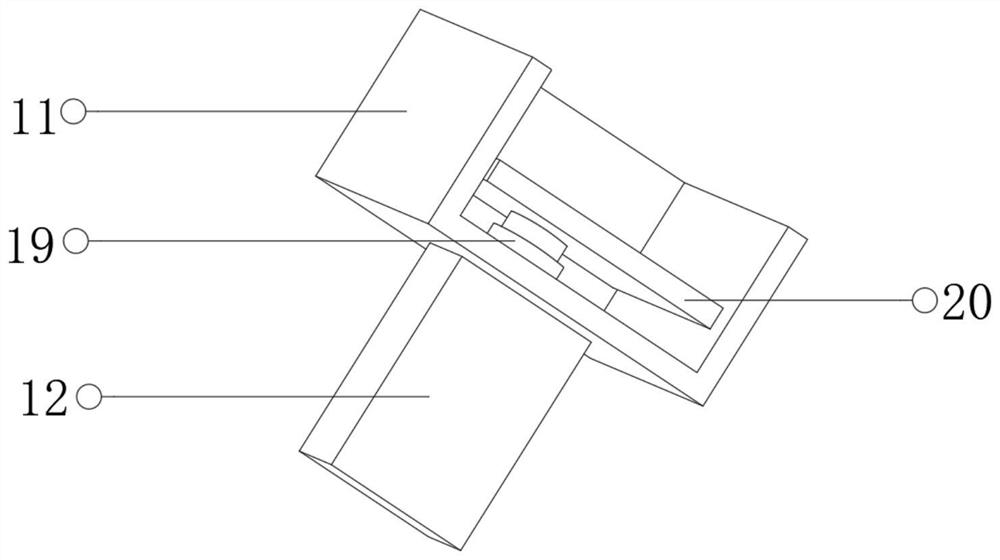

[0026] refer to Figure 1-3 , a device for detecting the flat surface of a wooden board for furniture processing, comprising a workbench 2, a support plate 3 connected by bolts to both sides of the top outer wall of the workbench 2, and a cover plate 5 connected to the top outer wall of the support plate 3 by bolts, the cover plate 5 There is a chute 8 in the middle, and the inner walls on both sides of the chute 8 are slidably connected with sliding blocks, and the outer wall at the bottom of the sliding block is connected with a conduction pipe 9 through bolts, and the end of the conduction pipe 9 away from the cover plate 5 is connected with a spraying material through bolts. The nozzle 10 is embedded with a sliding ball 18 inside the material spraying nozzle 10, and the sliding ball 18 partly extends out of the material spraying nozzle 10, the sliding ball 18 rolls freely inside the material spraying nozzle 10, the outer wall of the top of the sliding ball 18 is provided wi...

Embodiment 2

[0030] refer to Figure 4 , a wooden board surface flatness detection device for furniture processing, further comprising a horizontal plate 21 connected to the outer walls on both sides of the two limit boxes 11 by bolts, and a second electric telescopic panel connected to the outer walls on the opposite side of the horizontal plate 21 by bolts. The rod 23 and the ends of the plurality of second electric telescopic rods 23 away from the horizontal plate 21 are all connected to the limiting plate 22 by bolts.

[0031]Working principle: When in use, first place the plank 4 to be detected above the two limit boxes 11, and control the first electric telescopic rod to stretch or shrink so that the top outer wall of the plank 4 is higher than the top outer wall of the limit box 11, and the second The electric telescopic rod 23 can fix the wooden board 4 in the horizontal direction, avoiding the shaking of the wooden board 4 during detection and causing inaccurate results, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com