Biological capsule filling machine for pharmacy

A bio-capsule and filling machine technology, applied in the directions of drug delivery, capsule delivery, pharmaceutical formulation, etc., can solve the problems of complex internal transmission mechanism and difficult maintenance, and achieve the effect of facilitating filling operation, avoiding more or less addition, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

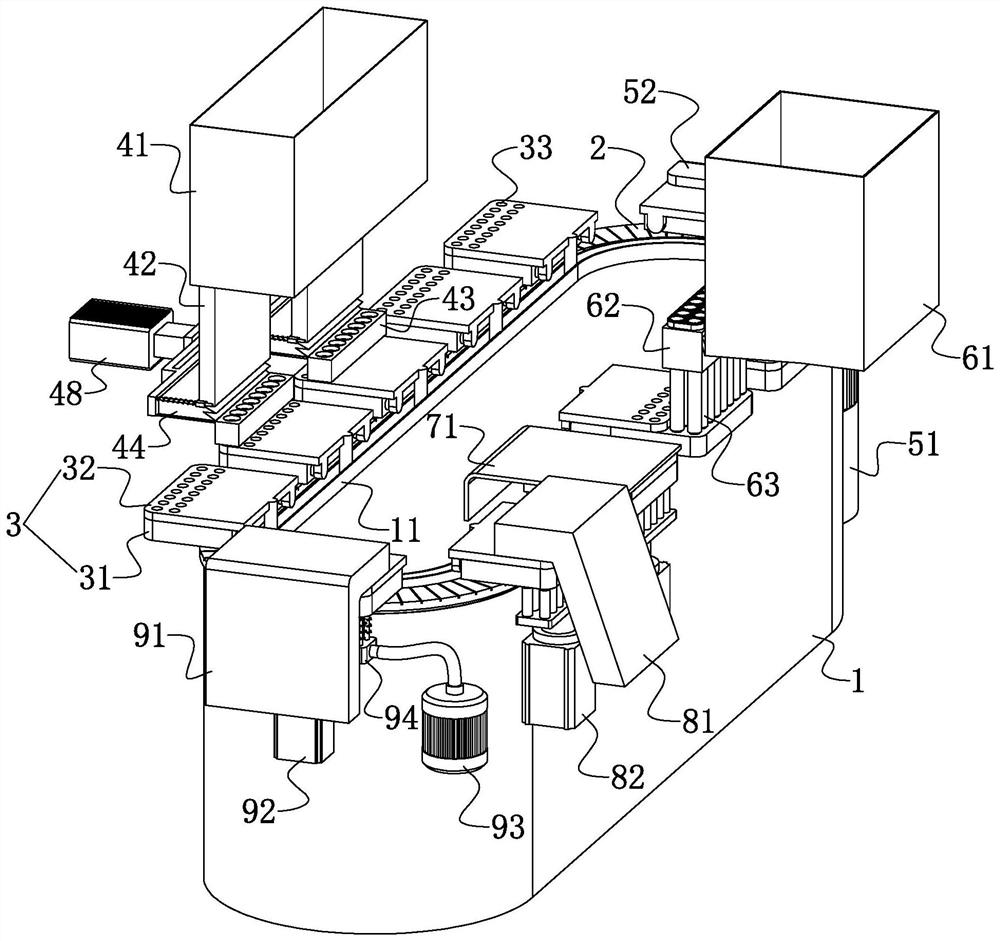

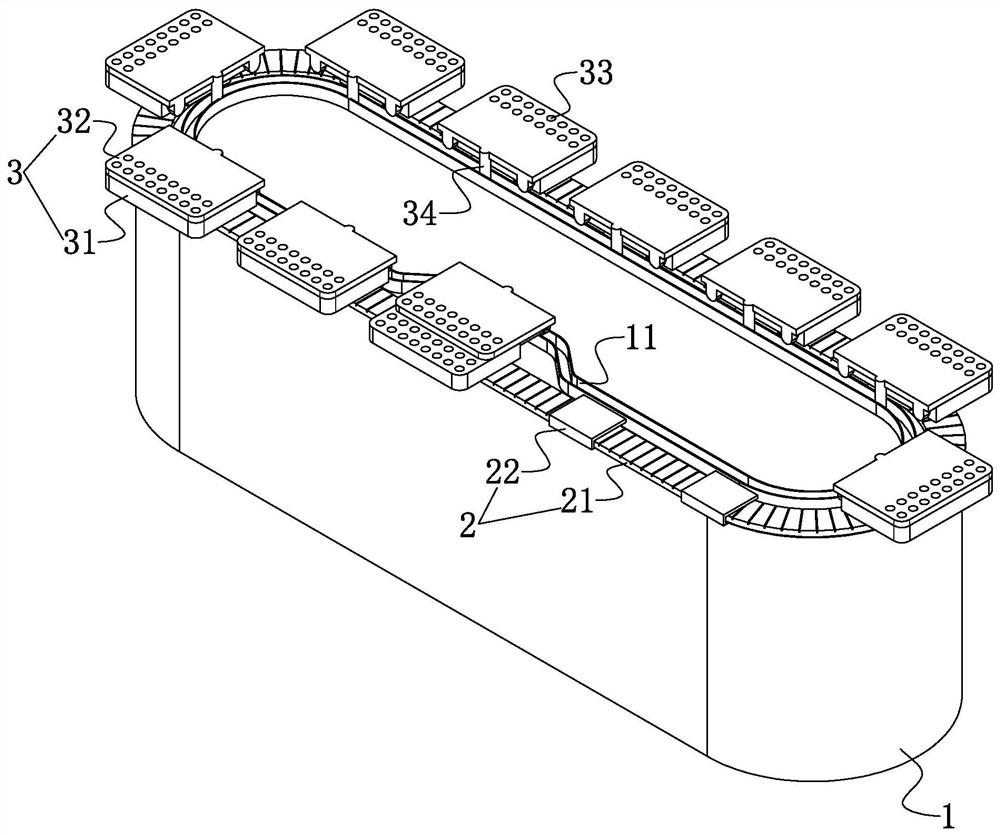

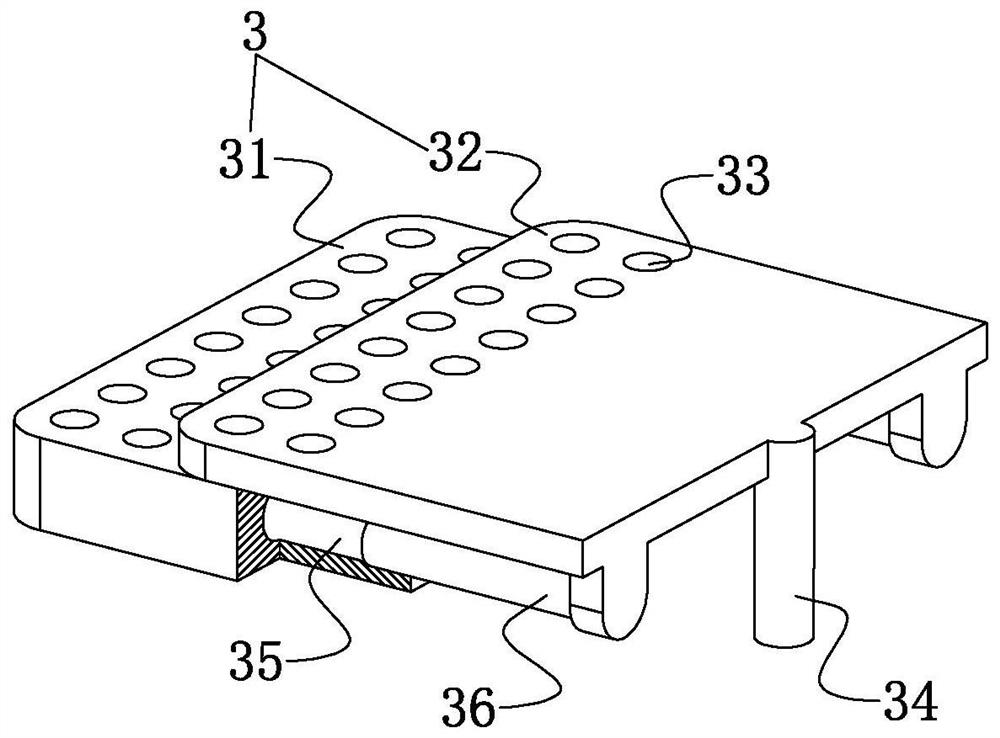

[0043] Examples, see Figure 1-9 , a pharmaceutical biocapsule filling machine, comprising a workbench 1, a ring-shaped linear motor 2 is installed on the upper end of the workbench 1, and the ring-shaped linear motor 2 includes a ring-shaped magnetic rail 21 installed along the edge of the workbench 1. The mover 22 that slides on the magnetic track 21, each mover 22 is provided with a capsule separation module 3 at the upper end, and the capsule separation module 3 includes a lower capsule tray 31 connected with the mover 22, and a capsule that slides back and forth along the lower capsule tray 31. The upper capsule plate 32 of each capsule separation module 3 is provided with a plurality of capsule filling grooves 33 downwards. The upper end of the workbench 1 is provided with an annular slide rail 11 in the annular magnetic track 21, and each upper capsule plate 32 Each is provided with a sliding shaft 34 that slides along the ring-shaped slide rail 11, and each lower capsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com