Board-level radio frequency signal test system, method and device without radio frequency test socket

A radio frequency test socket and radio frequency signal technology, which is applied in transmitter monitoring, receiver monitoring, etc., can solve the problems of limited motherboard design space, failure to improve the quality of radio frequency signal transmission and reception on wireless product boards, and increase the material cost of wireless products. Rigorous test, fast RF signal test, ingenious structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

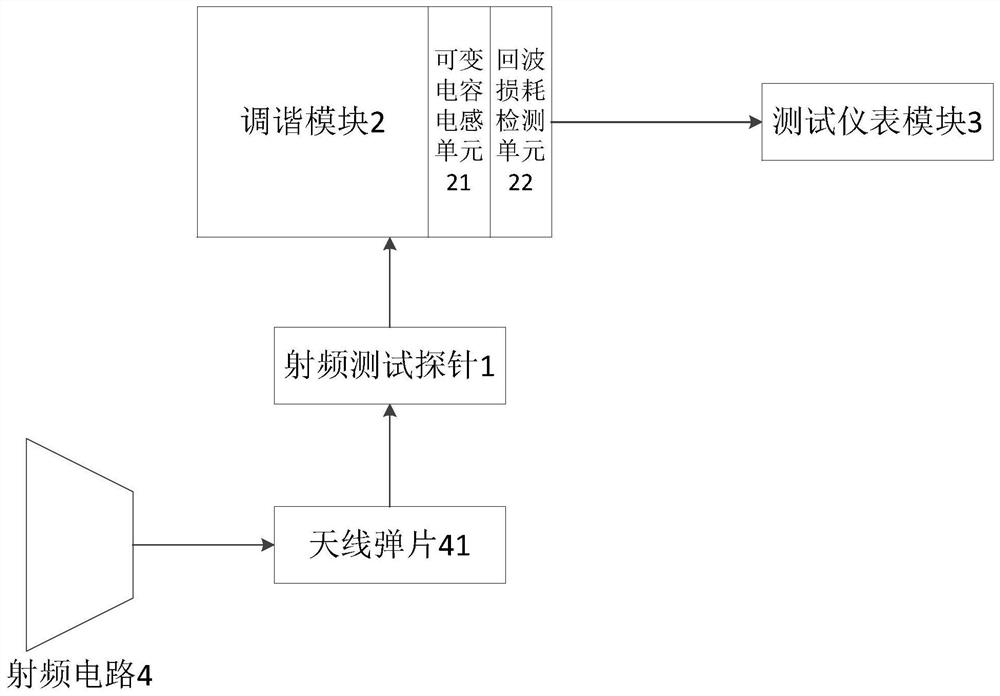

[0034] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

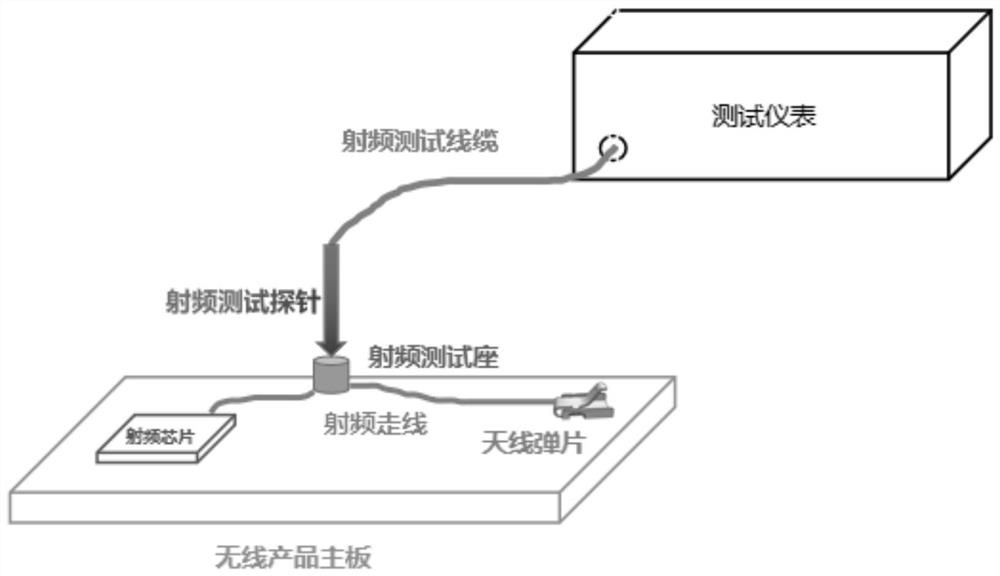

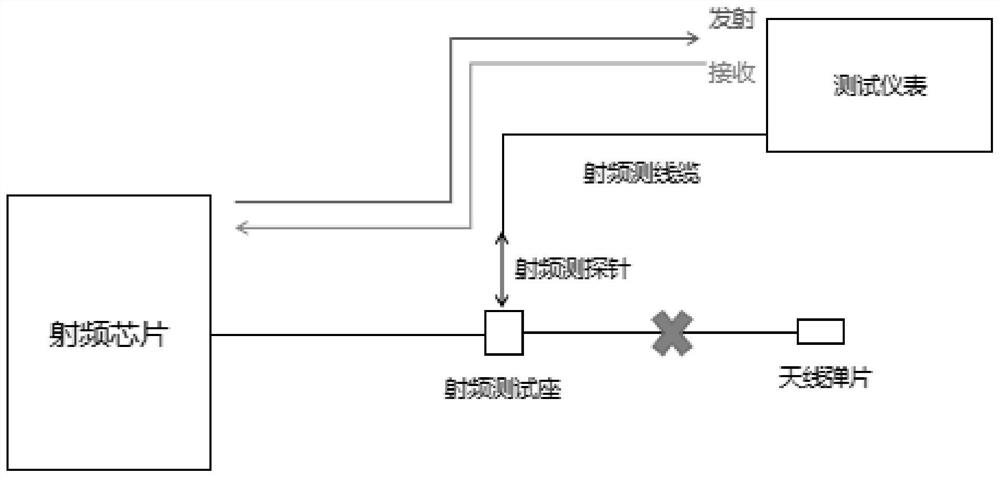

[0035] The function of the RF test socket is to form an electrical connection by mechanically snapping the RF probe and the RF test socket when performing board-level RF performance tests on wireless products; then when the RF signal sent or received by the RF chip on the motherboard of the wireless product , the signal will be transmitted to the test instrument through the RF test socket and the RF probe to test the RF signal; after the test is completed, pull out the probe; Antenna shrapnel, the radio frequency signal is sent by the antenna shrapnel to achieve the purpose of wireless communication; see figure 2 , Therefore, the function of the RF test socket is only to test the test requirements of the RF signal quality in the RF circuit, and does not contribute to the improvement of the RF signal quality itsel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com