An air blast sandblasting erosion wear tester

A wear test, air jet technology, applied in the direction of testing wear resistance, etc., can solve the problems of uneven feeding, inaccurate, no test exhaust gas filtration and purification, etc., to achieve the effect of simple operation and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand and implement, specific implementation examples are given below in conjunction with the accompanying drawings to describe the present invention in detail.

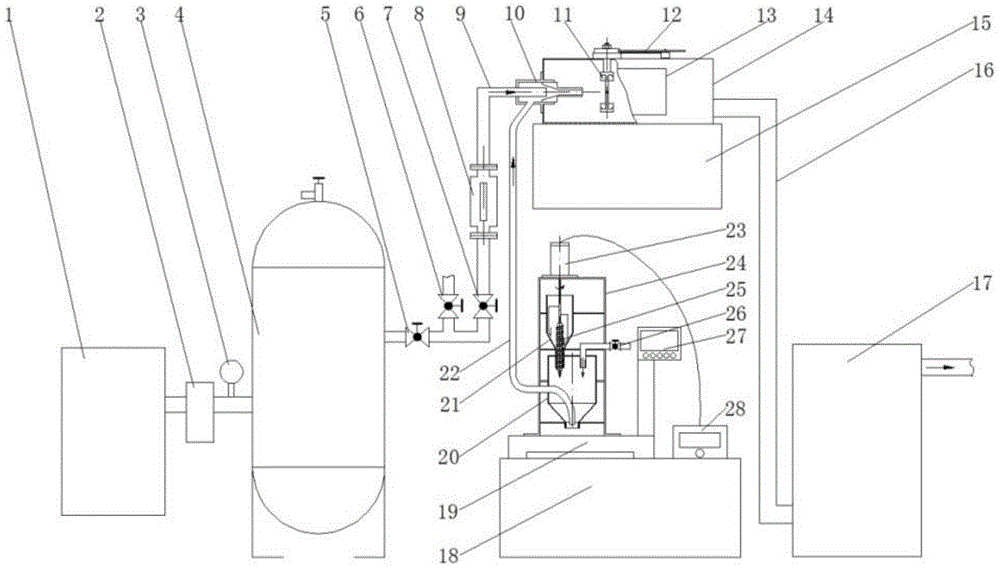

[0029] Such as figure 1 As shown, the airflow sandblasting erosion and wear testing machine mainly consists of four parts: high-speed airflow unit, screw feeding unit, erosion test unit and purification and dust removal unit.

[0030] The high-speed airflow unit is mainly composed of an air compressor 1, a dryer 2, a pressure gauge 3, an air storage tank 4, a valve a5, a valve b6, a valve c7, and a glass rotameter 8. The air compressor 1 is connected to the air storage tank 4, and a drier and a pressure gauge are arranged on the connection circuit between the air compressor and the air storage tank 4, and the air storage tank 4 is connected to the suction spray gun through the air flow pipeline 10 are connected, and valve a5, valve b6, valve c7 and glass rotameter 8 are set on the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com