A PLC type optical power splitter with adjustable power division ratio and its preparation method and adjustment method

An optical power splitter and adjustment method technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of high design difficulty, high nonlinearity, poor thermal stability of polymers, etc., and achieve finely adjustable power division ratio, The effect of low driving voltage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned power split ratio adjustable PLC type optical power splitter comprises the following steps:

[0047] Step 10): Take a silicon substrate 1 and clean the silicon wafer by wet chemical method;

[0048] Step 20): preparing a silicon dioxide buffer layer 2 on the silicon substrate 1 by thermal oxidation;

[0049] Step 30): Doping germanium dioxide into the silicon dioxide buffer layer 2 by using a plasma-enhanced chemical vapor deposition method to obtain a waveguide layer 3;

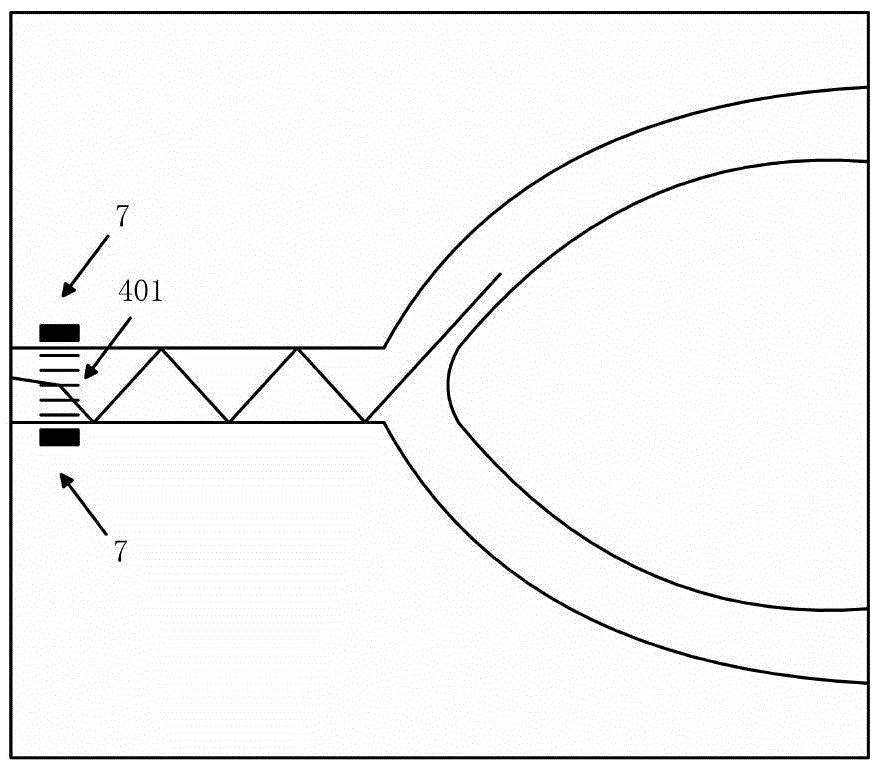

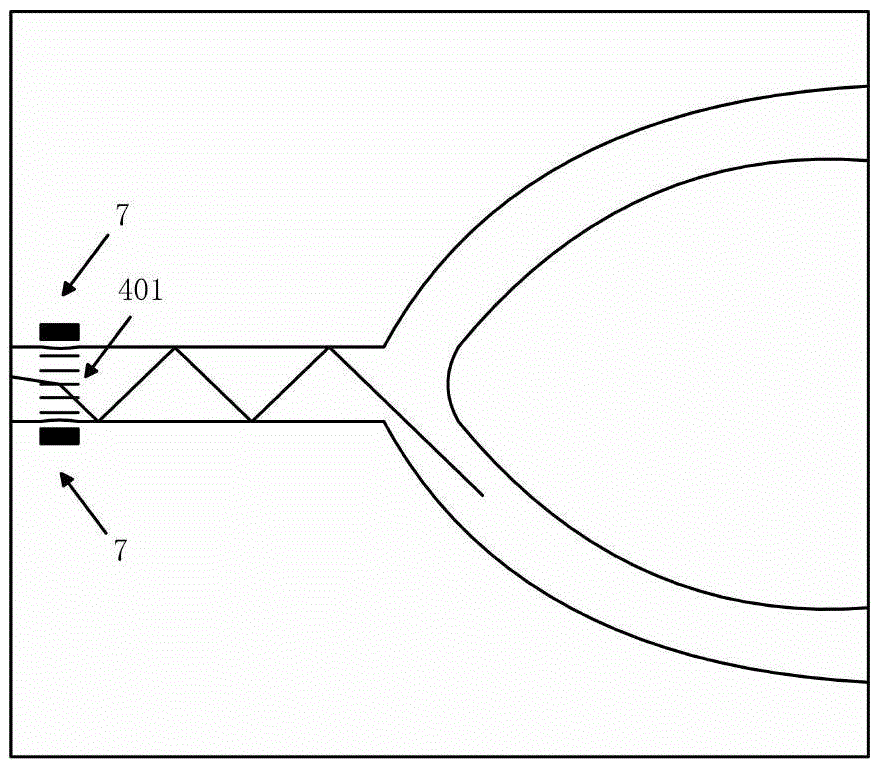

[0050] Step 40): using photolithography and etching process to prepare waveguide 4 on waveguide layer 3, waveguide 4 includes n-level shunt structure, and i-th-level shunt structure includes 2 i-1 branching units, and each branching unit is Y-shaped, each branching unit includes an input waveguide and two output waveguides, and each branching unit is provided with a waveguide grating 401;

[0051] Step 50): using a high-temperature annealing process to g...

Embodiment 1

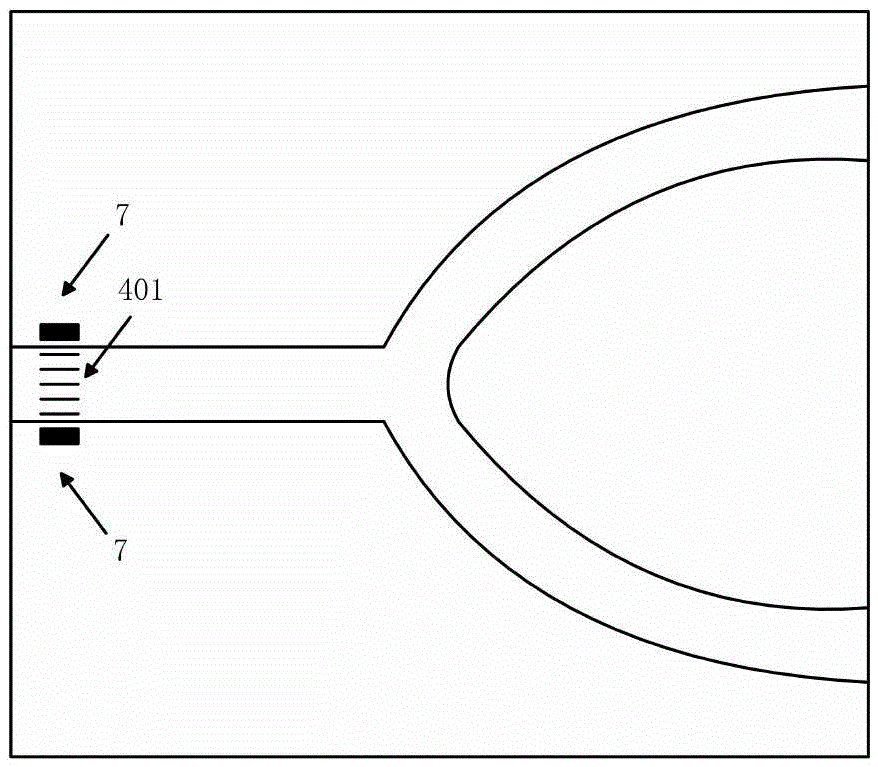

[0061] Such as figure 1 As shown, a PLC type 1×2 optical power splitter with adjustable power division ratio adopts a planar light wave optical circuit PLC chip, and the planar light wave optical circuit PLC chip includes a silicon substrate 1 and a silicon dioxide buffer grown on the silicon substrate 1 Layer 2, a waveguide 4 grown on the silicon dioxide buffer layer 2, a cover layer 5 grown on the waveguide 4, two electrodes 7 deeply etched on the cover layer 5, the waveguide 4 includes a 1-level Y-shaped shunt structure, A level 1 shunt structure consists of a shunt unit. One input waveguide of the branching unit is the input end of the power splitter, and the two output waveguides are the output ends of the power splitter. A waveguide grating 401 is arranged on the input waveguide, and electrodes 7 are deeply etched on both sides of the waveguide grating 401 . The power divider applies different intensities of driving voltage to the electrostatic adjustable grating, chan...

Embodiment 2

[0063] Introduce the preparation method of embodiment 1 optical power splitter below, this preparation method comprises the following steps:

[0064] Step 10): making the silicon dioxide buffer layer 2 and the waveguide 3 . refer to Figure 4 As shown, it includes step 101), step 102) and step 103).

[0065] Step 101) Take a silicon substrate 1, use a wet chemical method to clean the silicon wafer as the silicon substrate 1, and remove the dirt on the surface; then, after ultrasonic cleaning and drying with deionized water, the cleaning of the silicon wafer is completed;

[0066] Step 102) Prepare the silica buffer layer 2. There are many methods for preparing the silica buffer layer 2, such as chemical vapor deposition (CVD), flame hydrolysis (FHD), sol-gel method (Sol-Gel), Thermal oxidation (TO), etc. Since the thermal oxidation method can oxidize hundreds of silicon wafers at the same time, it has high efficiency in actual production, and can simultaneously oxidize the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com