Socket, plugs and pluggable device for connecting high-voltage cables

A high-voltage cable and plug-in technology, which is applied to the parts, connections, and two-part connection devices of the connecting device, can solve the problems of inconvenient folding, hidden safety hazards, and high costs, and achieves easy to pick up and prevent falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

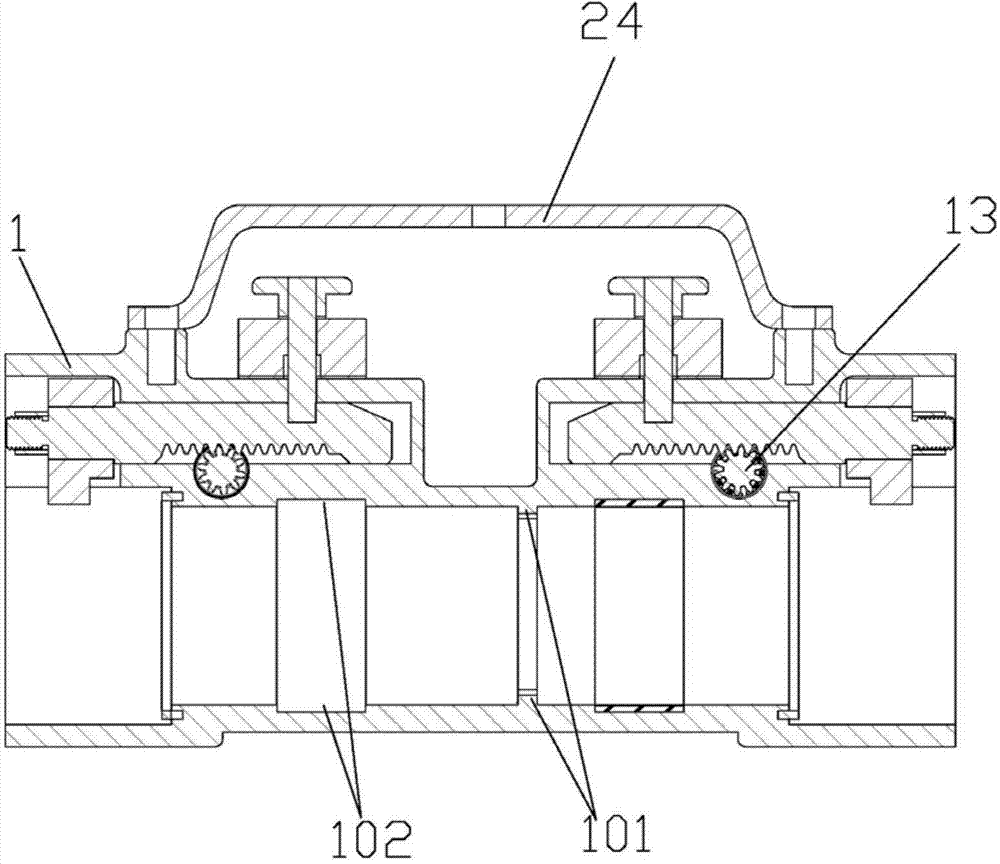

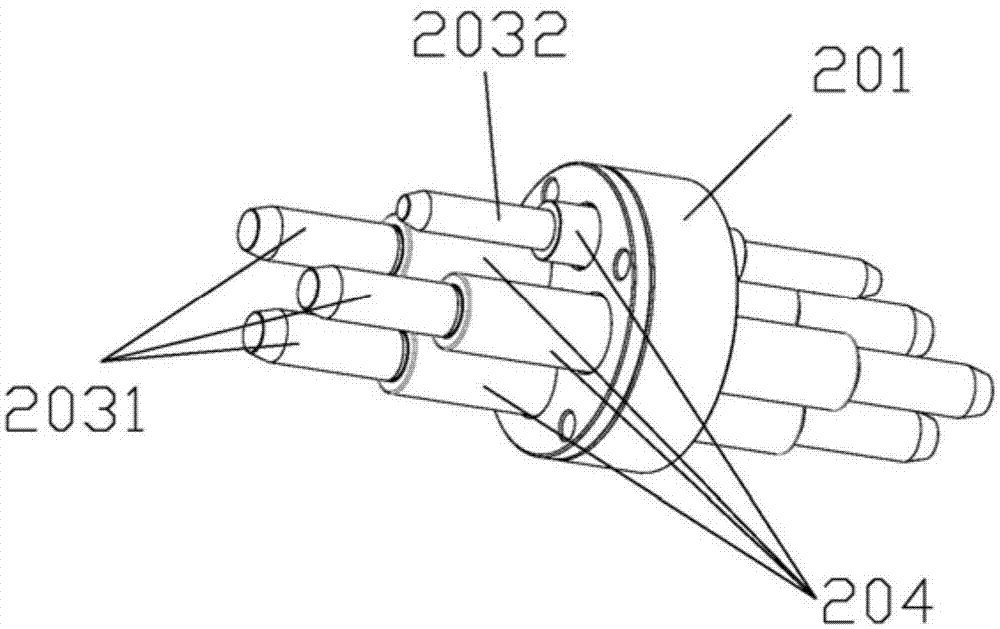

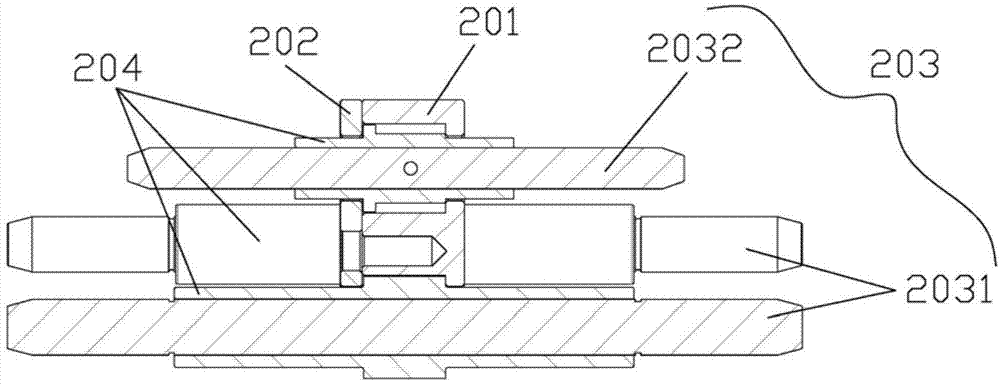

[0044] Such as Figure 1-3 As shown, the present invention provides a socket for connecting high-voltage cables, including a socket housing 1 and a pin assembly 2, the pin assembly 2 is placed in the socket housing 1, and the socket housing The body 1 is provided with a limit protrusion 101 and a first groove 102, one side of the pin assembly 2 is close to the limit protrusion 101, and a ground spring is placed in the first groove 102 Circle 3; the pin assembly 2 includes a pin fixing block 201, a fixing block cover plate 202, a pin 203 and a pin insulating sleeve 204 sleeved outside the pin, and the pin 203 and the pin insulating sleeve 204 pass through the pin fixing block 201 and are fixed in the pin fixing block, the fixing block cover plate 202 is fixed on the pin fixing block 201, the The pins 203 include three conductive pins 2031 and one ground pin 2032 .

[0045] The contact pins in the socket for connecting high-voltage cables provided by the present invention are ...

Embodiment 2

[0047] Such as Figure 4-7As shown, the present invention also provides a plug for connecting high-voltage cables, including a plug housing 4 and an insulator assembly 5, the plug housing 4 is partly sleeved outside the insulator assembly 5, and the insulator The assembly 5 includes an insulator 501, an insulator sleeve 502 sleeved outside the insulator, a socket member 503 and an inner conductor 504, and the plug housing 4 and the insulator sleeve 502 are fixedly fitted by threads. The insulator 501 is provided with a first through hole 505 for placing the jack 503. The jack 503 includes a connected cable jack 506 and a pin jack 507. The insulator is provided with four Jacks, three of which are conductive jacks 508, and the other is a ground wire jack 509, the pin sockets of the conductive jacks 508 are matched with conductive pins, and the conductive pins The cable jack of the hole part 508 is matched with the cable, the pin jack of the ground wire jack part 509 is matched ...

Embodiment 3

[0050] Such as Figure 8-13 As shown, the present invention further provides a plug-in device for connecting high-voltage cables, including a socket for connecting high-voltage cables in the first embodiment and two plugs for connecting high-voltage cables in the second embodiment. The two plugs described above are arranged on both sides of the socket respectively, the pins 203 in the socket are matched with the pin sockets 507 in the plug, and the plug housing One end of the plug housing is sealed butted with the socket housing through a first sealing ring 10 , and the other end of the plug housing is connected with a pressure plate cover 12 through a second sealing ring 11 . A plug and puller for connecting high-voltage cables provided by the present invention includes a plug and a socket for connecting disconnected cables, and a sealing ring is provided at the docking position of the plug and the socket and one end of the plug housing, so that Its tightness is better and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com