Floating connector

A technology for floating connectors and mounting panels, which is applied to the installation of connecting parts, etc., which can solve the problems of difficult disassembly, high manufacturing cost, and small floating amount, and achieve the effects of convenient installation and use, low manufacturing cost, and small space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below with specific embodiment, the present invention is further elaborated:

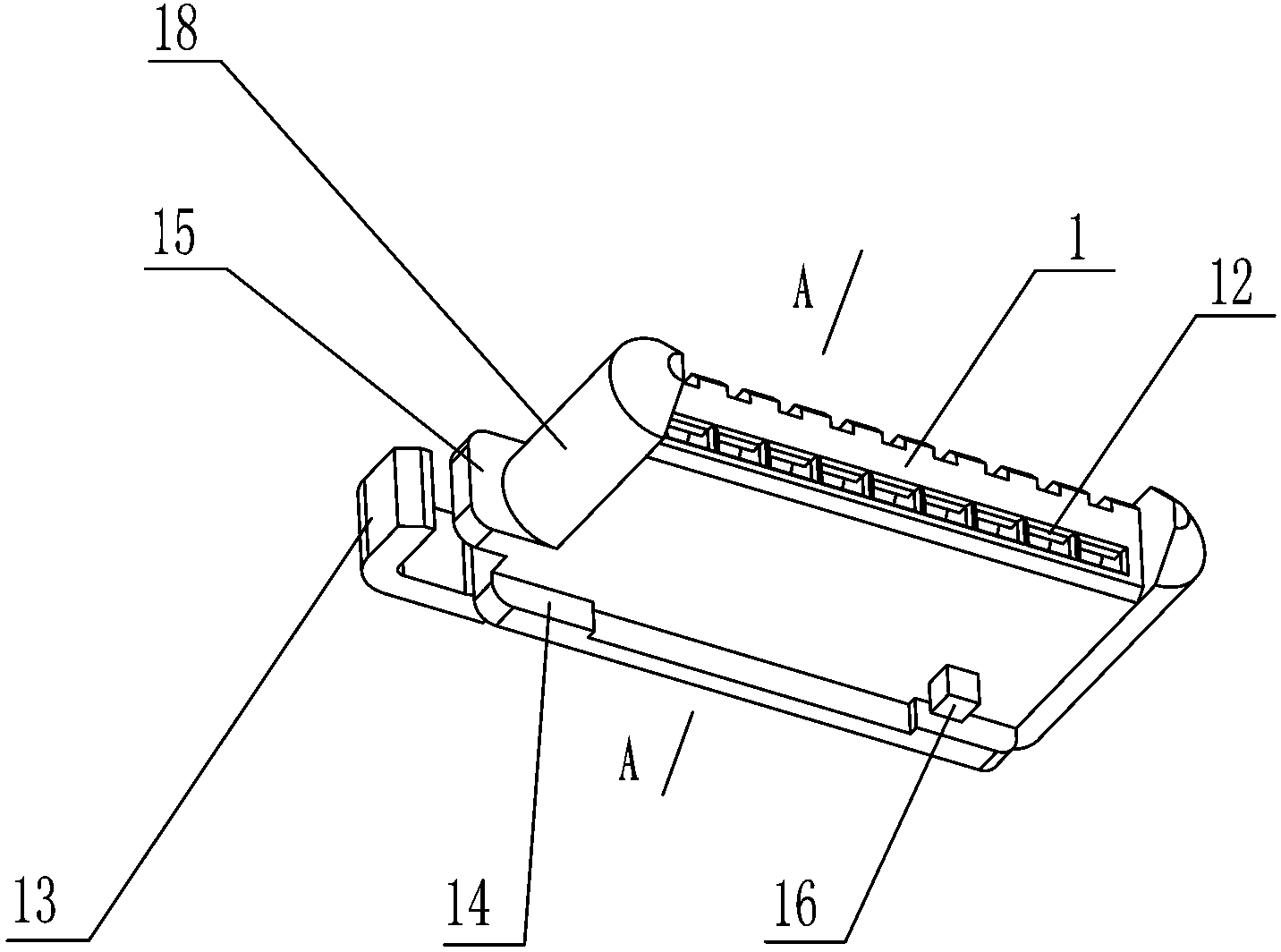

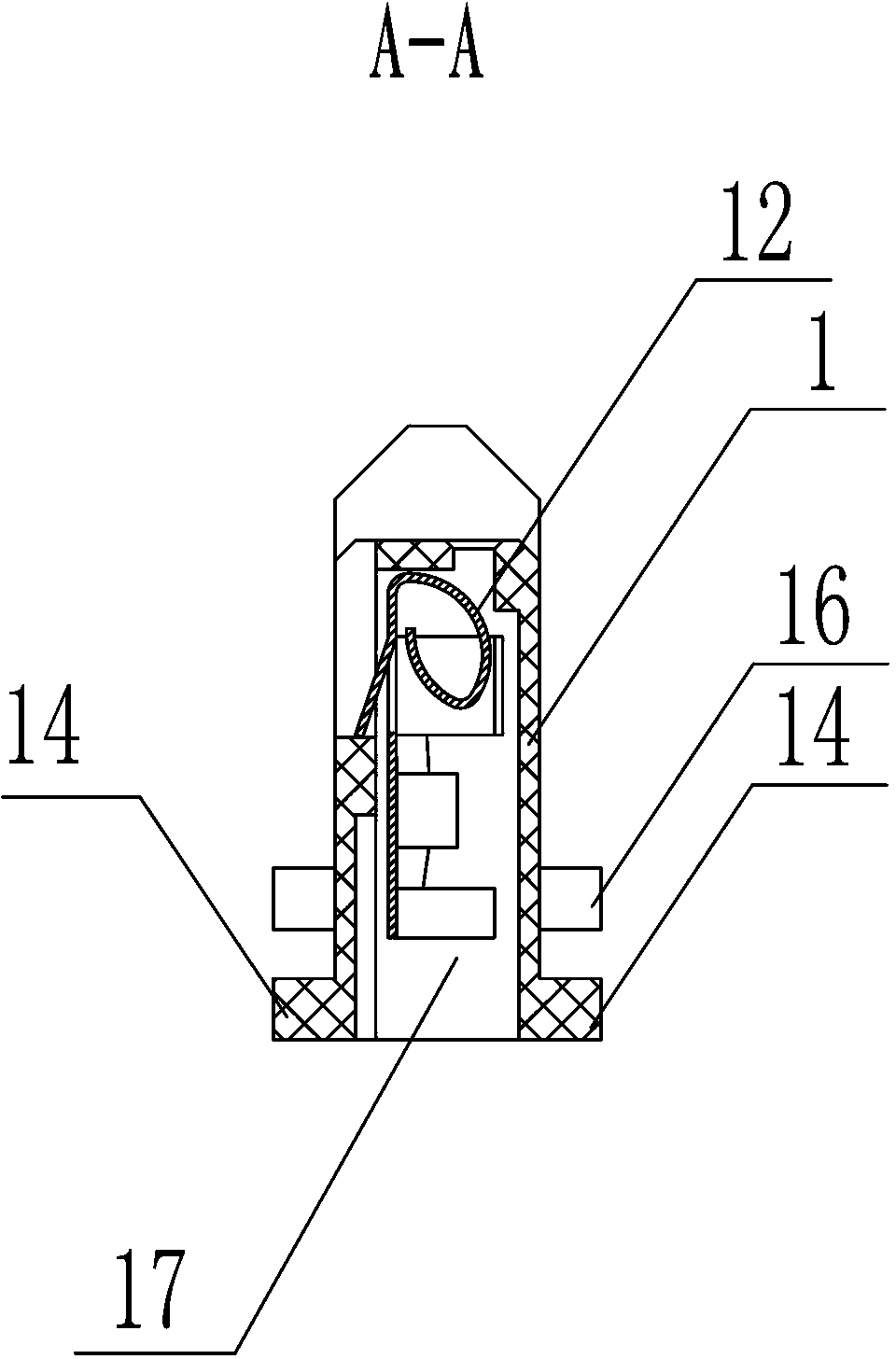

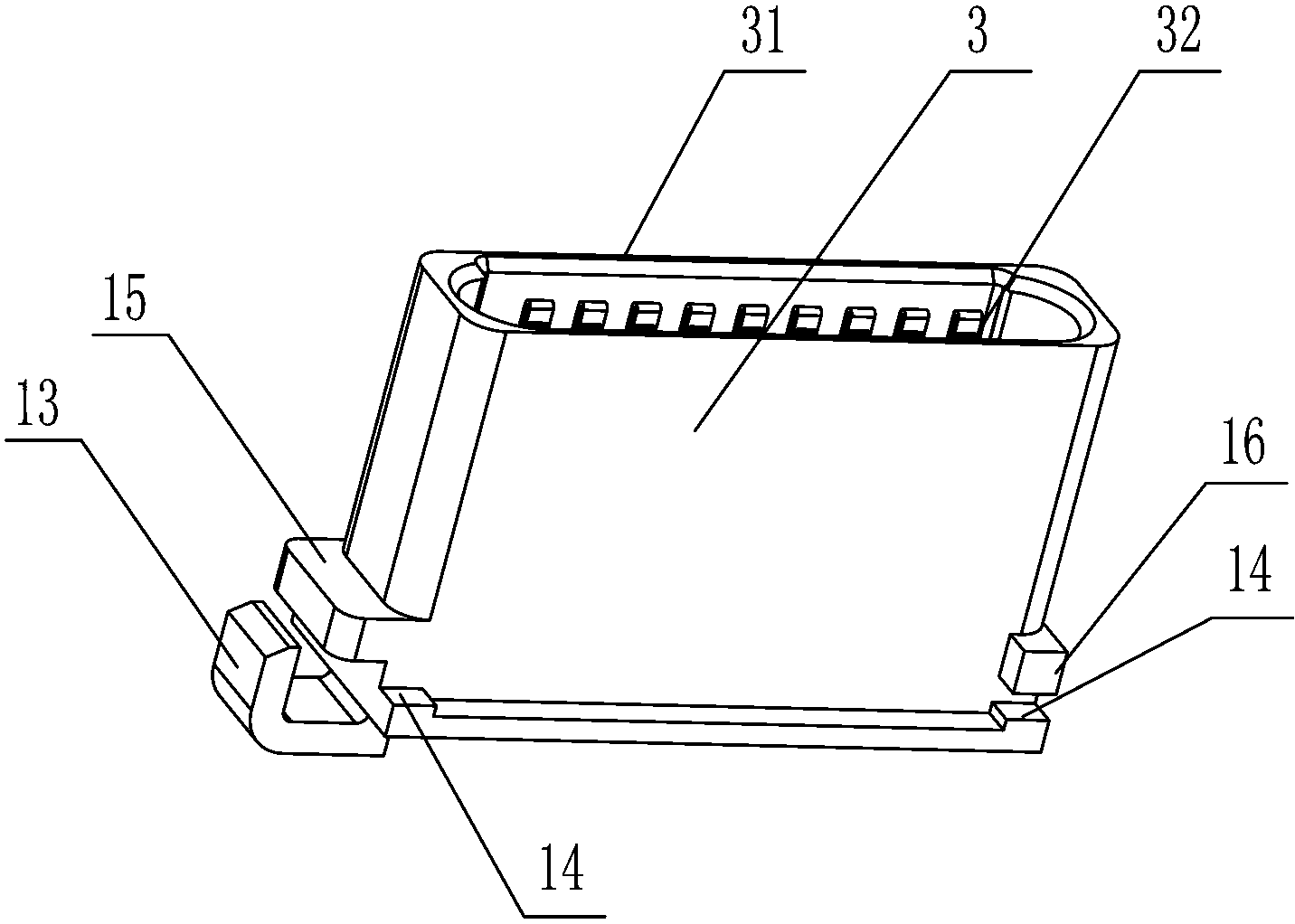

[0014] See attached figure 1 ~ attached figure 2 , the plug 1 of the present invention is composed of a contact terminal 12 arranged on an insulating base 11, two ends of the insulating base 11 are provided with guide structures 18, and one end of the bottom of one guide structure 18 is provided with an elastic arm 13 and an upper positioning Block 15, lower positioning blocks 14 and upper positioning projections 16 are provided on both sides of the bottom of the insulating base 11, guiding structures 18 are provided at both ends of the insulating base 11, and the lower positioning blocks 14 are symmetrically arranged on the bottoms of both ends of the insulating base 11 The distance between the upper positioning block 15, the upper positioning protrusion 16 and the lower positioning block 14 is greater than the thickness of the installation panel 2; Window 22; one end of the mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com