Chain link comprising an articulation section and a fork section separated by a slide section

A sliding segment and chain link technology, applied in the field of chain links, can solve the problem of expensive materials and achieve the effect of eliminating screaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

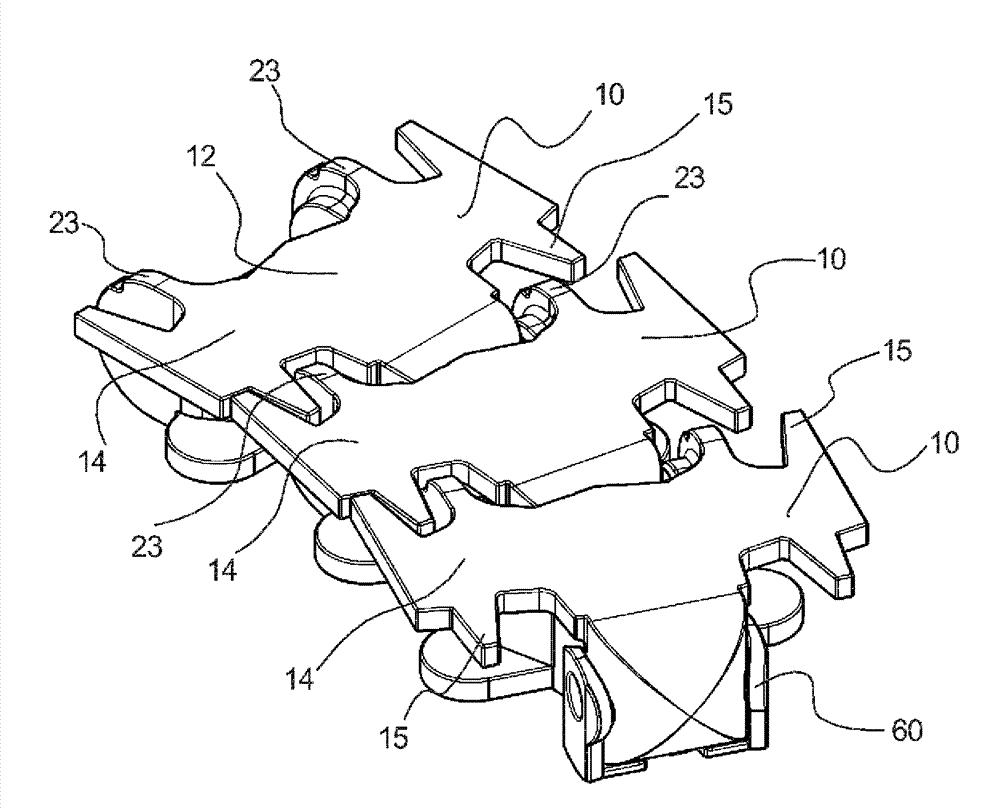

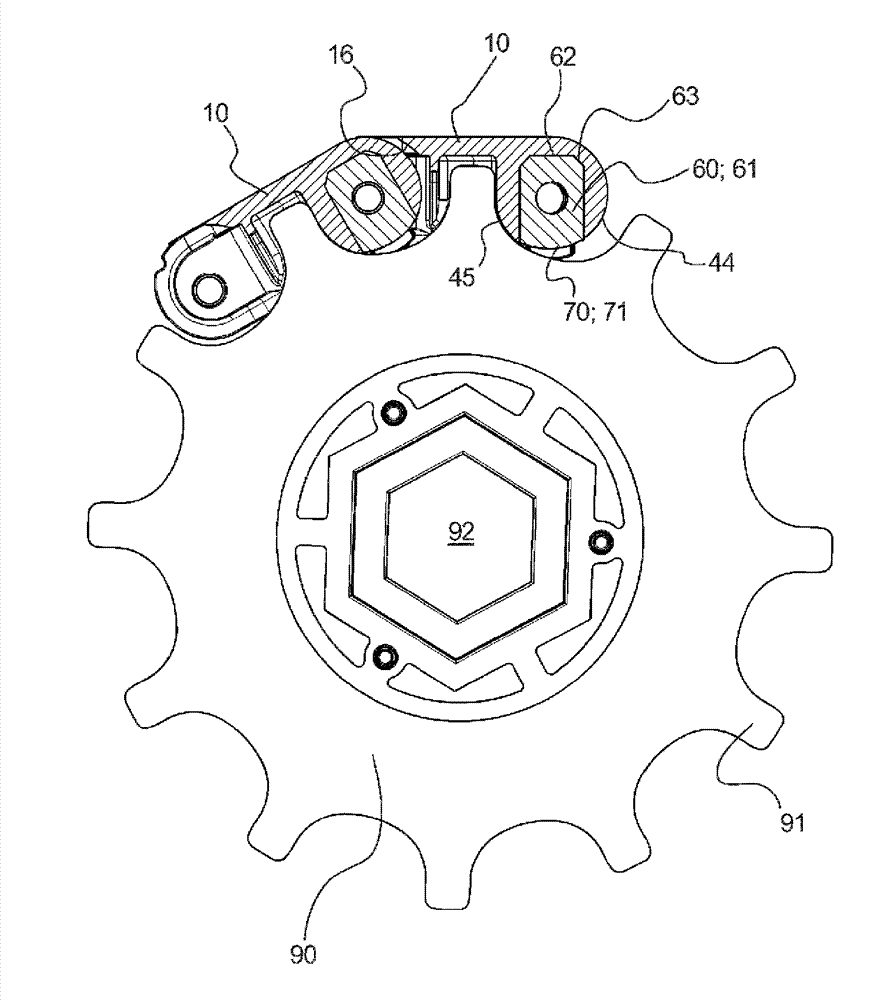

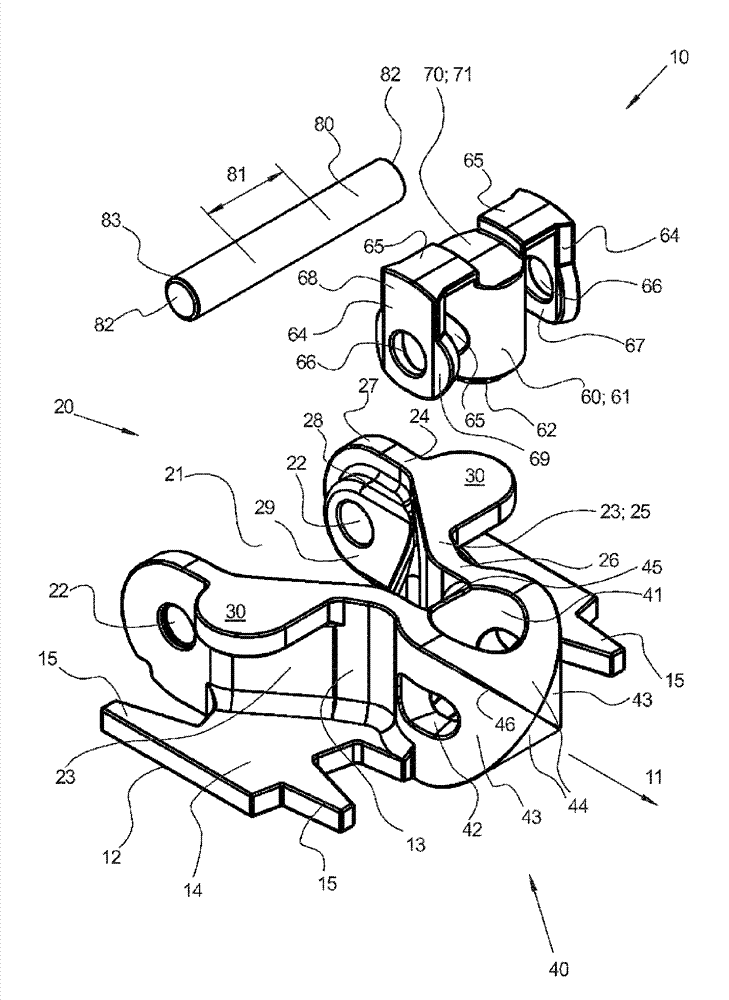

[0026] figure 1 An exploded view of a chain link 10 according to the invention is shown. Chain link 10 comprises a one-piece base body 13 made of polyoxymethylene, a one-piece articulation part 60 made of polyamide and a bolt 80 made of steel. The base body 13 and the hinge member 60 are respectively made by plastic die-casting.

[0027]The base body 13 , which is generally mirror-symmetrical, comprises a joint section and a fork section 40 ; 20 as well as a carrying means 14 . The carrying means is embodied in the form of a plate which defines a transport plane 12 . The plate 14 is provided with teeth 15 pointing in the conveying direction 11, so that the teeth 15 of adjacent base bodies 13 of a conveyor chain engage with each other, so that the (not shown) conveyed goods are as far as possible even when traveling in curves. supported on the surface. The flat plate 14 is arranged so close to the articulation section and the fork section 40 ; 20 that it does not transmit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com