Peach gum flakes and preparation method thereof

A technology of film and peach gum, applied in the field of peach gum film and its preparation, to achieve the effects of increasing flavor, low processing cost, and simple method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention comprises the steps:

[0025] (1) Pretreatment: Soak peach gum in water, wash away impurities and drain;

[0026] (2) Hydrolysis: put 100 parts by weight of pretreated peach gum into 200-300 parts by weight of boiling water, add 2-5 parts by weight of citric acid, and boil slightly for 120-160 minutes;

[0027] (3) Stirring: add acid-modified starch: 20-30 parts by weight, carrageenan 0.3-0.5 parts by weight, hydroxylated lecithin 0.6-0.8 parts by weight, sucrose ester 0.3-0.5 parts by weight, sucrose powder: 0-12 parts by weight , 0.0-0.06 parts by weight of protein sugar (aspartame), 0.05-0.2 parts by weight of peach essence, and stirred at a temperature of 80-90°C for 30-35 minutes;

[0028] (4) Injection molding: Put the stirred mixture into the mold together, and put the release agent at the bottom of the mold; then let it stand and cool naturally;

[0029] (5) Demoulding: Take out the injected mixture from the mold...

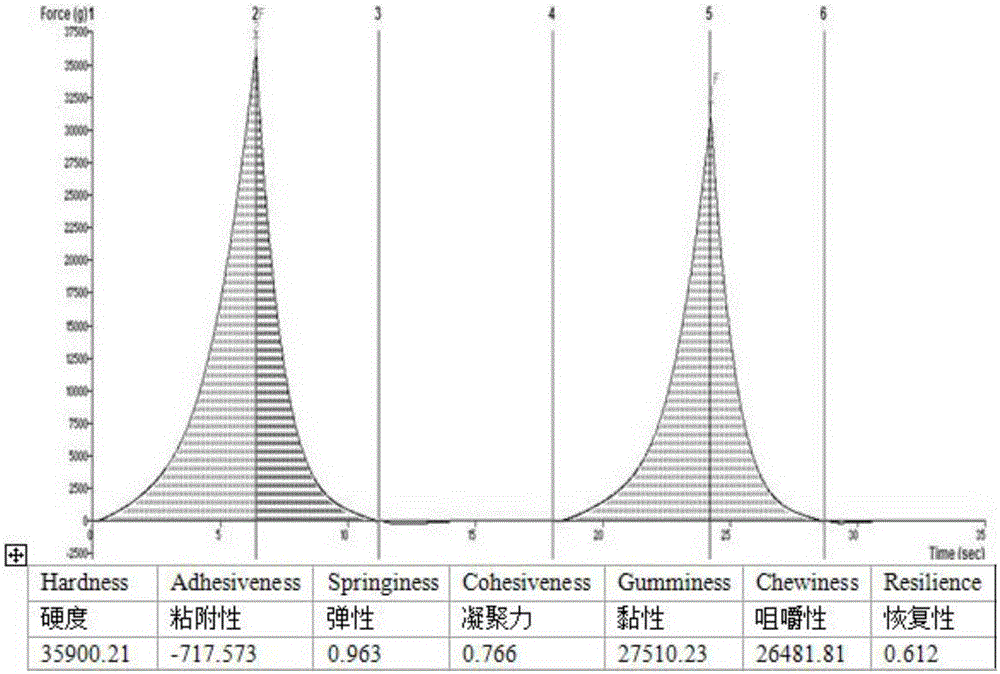

Embodiment 1

[0034] (1) Pretreatment: Soak peach gum in water, wash away impurities and drain;

[0035] (2) Hydrolysis: put 100 parts by weight of pretreated peach gum into 280 parts by weight of boiling water, add 4.5 parts by weight of citric acid, and boil for 150 minutes;

[0036] (3) Stirring: add acid-modified starch: 28 parts by weight, carrageenan 0.35 parts by weight, hydroxylated lecithin 0.65 parts by weight, sucrose ester 0.35 parts by weight, sucrose powder: 10 parts by weight, protein sugar (aspartame) 0.0 Parts by weight, 0.012 parts by weight of peach essence, stirred at 90°C for 35 minutes;

[0037] (4) Injection molding: Put the stirred mixture into the mold together, and put 0.25 parts by weight of the release agent calcium stearate into the bottom of the mold; then let it stand and cool naturally.

[0038] (5) Demoulding: Pour out the peach gum material from the mold and put it on the chopping board;

[0039] (6) Slicing: cut into 10mm×20mm×30mm slices;

[0040] (7) ...

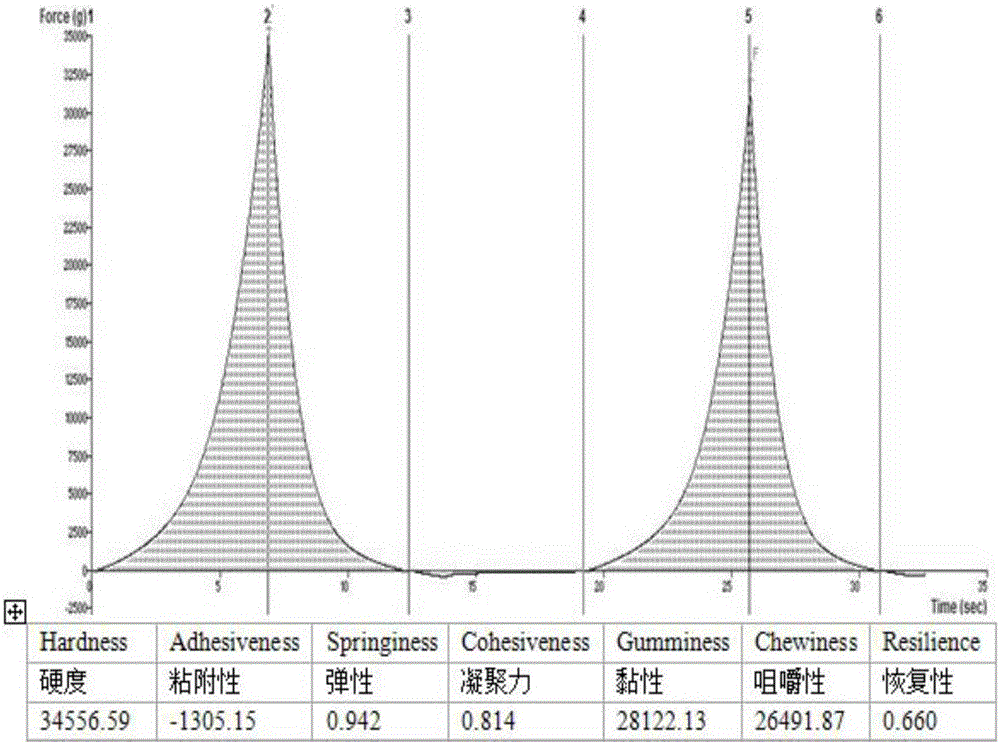

Embodiment 2

[0044] (1) Pretreatment: Soak peach gum in water, wash away impurities and drain;

[0045] (2) Hydrolysis: put 100 parts by weight of pretreated peach gum into 260 parts by weight of boiling water, add 4.2 parts by weight of citric acid, and boil for 155 minutes;

[0046] (3) Stirring: add acid-modified starch: 27 parts by weight, carrageenan 0.45 parts by weight, hydroxylated lecithin 0.7 parts by weight, sucrose ester 0.35 parts by weight, sucrose powder: 0 parts by weight, protein sugar (aspartame) 0.055 Parts by weight, 0.015 parts by weight of peach essence, stirred at 90°C for 32 minutes;

[0047] (4) Injection molding: Put the stirred mixture into the mold together, and put 0.26 parts by weight of the release agent calcium stearate into the bottom of the mold; then let it stand and cool naturally.

[0048] (5) Demoulding: Pour out the peach gum material from the mold and put it on the chopping board;

[0049] (6) Slicing: cut into 10mm×20mm×30mm slices;

[0050] (7) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com