Practical shoe take-off shoe

A shoe slipper, a practical technology, applied in the field of shoe slipper manufacturing, can solve the problems of unsightly occupied space, inconvenient help, inconvenience, etc., and achieve the effect of convenient manufacturing and installation and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

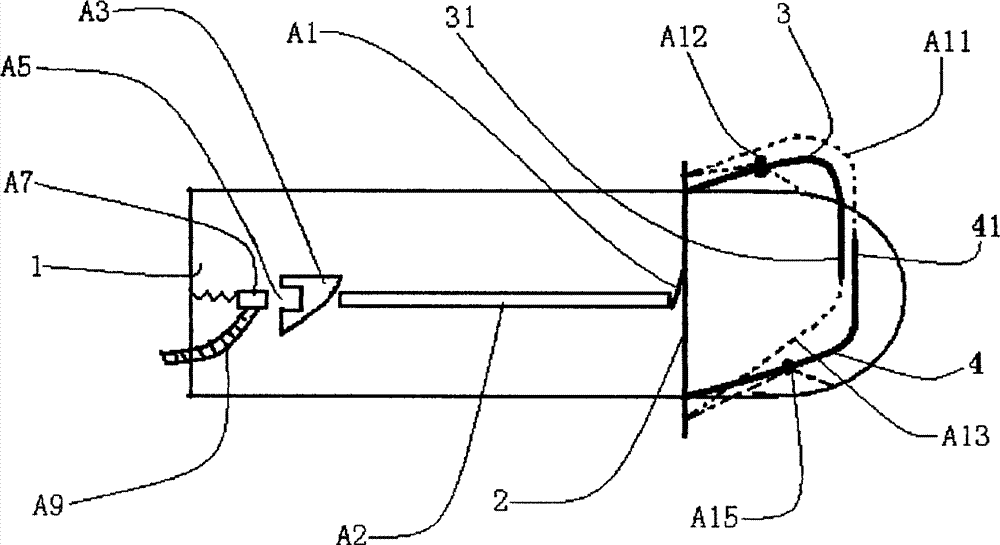

Embodiment 1

[0019] A practical shoe slipper, comprising a base body 1 matching the sole, the base body 1 is used to cover the sole, a rotating shaft 2, a left spring piece 3, a right spring piece 4, a transmission device, a cooperating device, a buckle, a solution Fastener; the rotating shaft 2 traverses the base body 1 and is rotationally connected with the base body 1; one end of the left spring piece 3 is connected to the left end of the rotating shaft 2, and the other end is curved to the right, and the end of the left spring piece 3 bent to the right is called the first One bend 31, one end of the right spring piece 4 is connected to the right end of the rotating shaft 2, and the other end is curved to the left. The end of the right spring piece 4 bent to the left is called the second bend 41, the first bend 31 and The second bend 41 overlaps each other so that the left spring piece 3 and the right spring piece 4 jointly form a half ring; The rotation drives the half ring to turn ove...

Embodiment 2

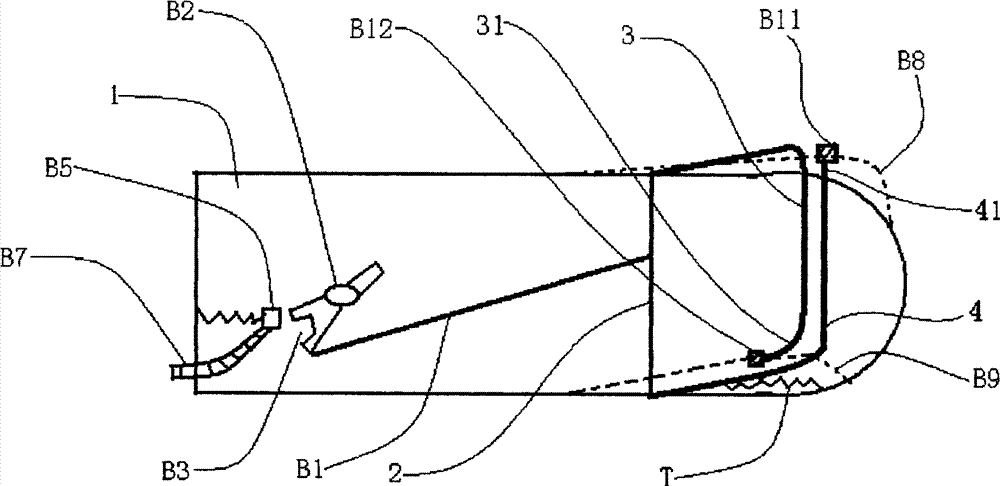

[0023] A practical shoe slipper, comprising a base body 1 matching the sole, the base body 1 is used to cover the sole, a rotating shaft 2, a left spring piece 3, a right spring piece 4, a transmission device, a cooperating device, a buckle, a solution Fastener; the rotating shaft 2 traverses the base body 1 and is rotationally connected with the base body 1; one end of the left spring piece 3 is connected to the left end of the rotating shaft 2, and the other end is curved to the right, and the end of the left spring piece 3 bent to the right is called the first One bend 31, one end of the right spring piece 4 is connected to the right end of the rotating shaft 2, and the other end is curved to the left. The end of the right spring piece 4 bent to the left is called the second bend 41, the first bend 31 and The second bend 41 overlaps each other so that the left spring piece 3 and the right spring piece 4 jointly form a half ring; The rotation drives the half ring to turn ove...

Embodiment 3

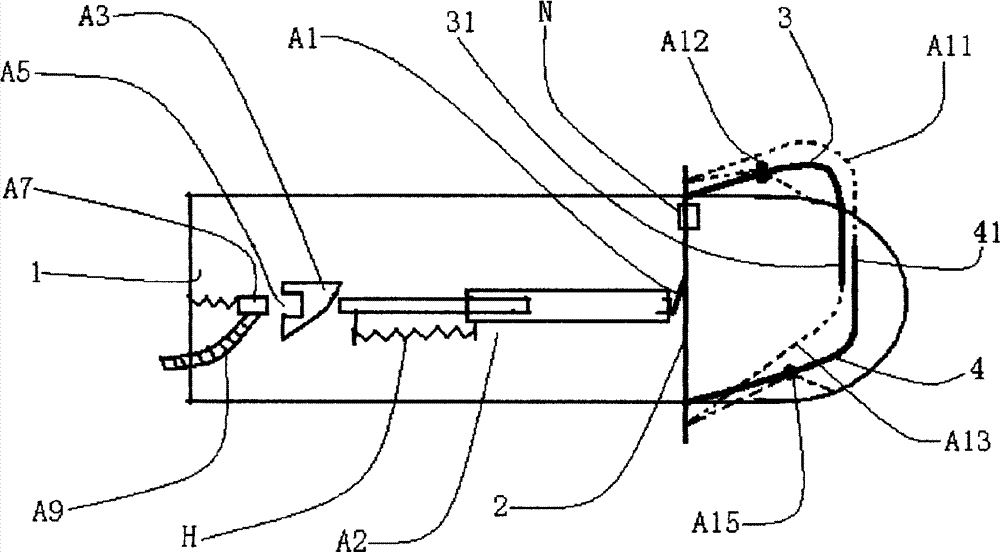

[0029] A practical shoe slipper, comprising a base body 1 matching the sole, the base body 1 is used to cover the sole, a rotating shaft 2, a left spring piece 3, a right spring piece 4, a transmission device, a cooperating device, a buckle, a solution Fastener; the rotating shaft 2 traverses the base body 1 and is rotationally connected with the base body 1; one end of the left spring piece 3 is connected to the left end of the rotating shaft 2, and the other end is curved to the right, and the end of the left spring piece 3 bent to the right is called the first One bend 31, one end of the right spring piece 4 is connected to the right end of the rotating shaft 2, and the other end is curved to the left. The end of the right spring piece 4 bent to the left is called the second bend 41, the first bend 31 and The second bend 41 overlaps each other so that the left spring piece 3 and the right spring piece 4 jointly form a half ring; The rotation drives the half ring to turn ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com