Gluing device in medical apparatus mounting equipment

A technology for assembling equipment and gluing devices, which is applied to the device and coating of surface coating liquid, which can solve the problems of uncontrollable gluing amount and low gluing automation, and achieve the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

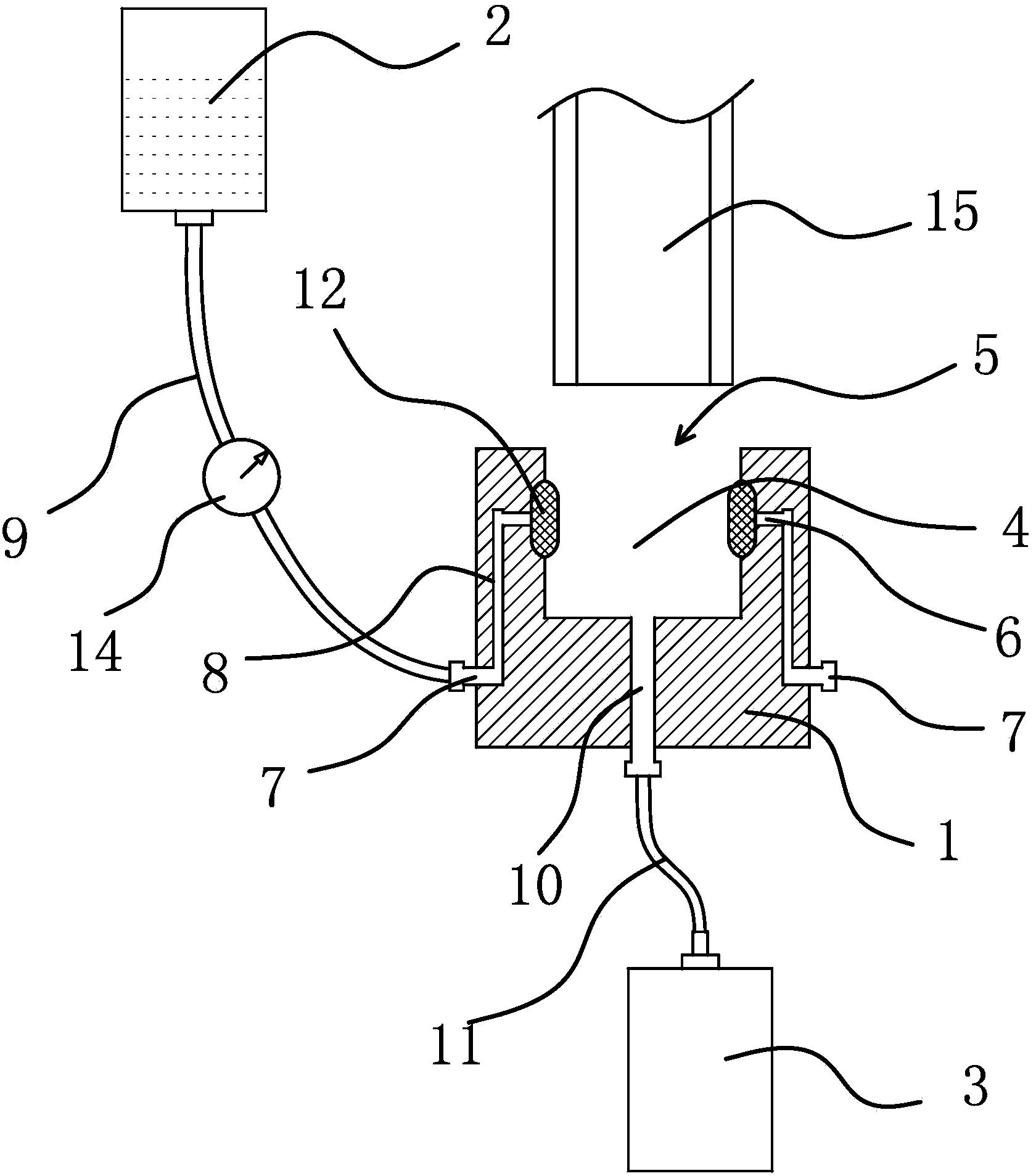

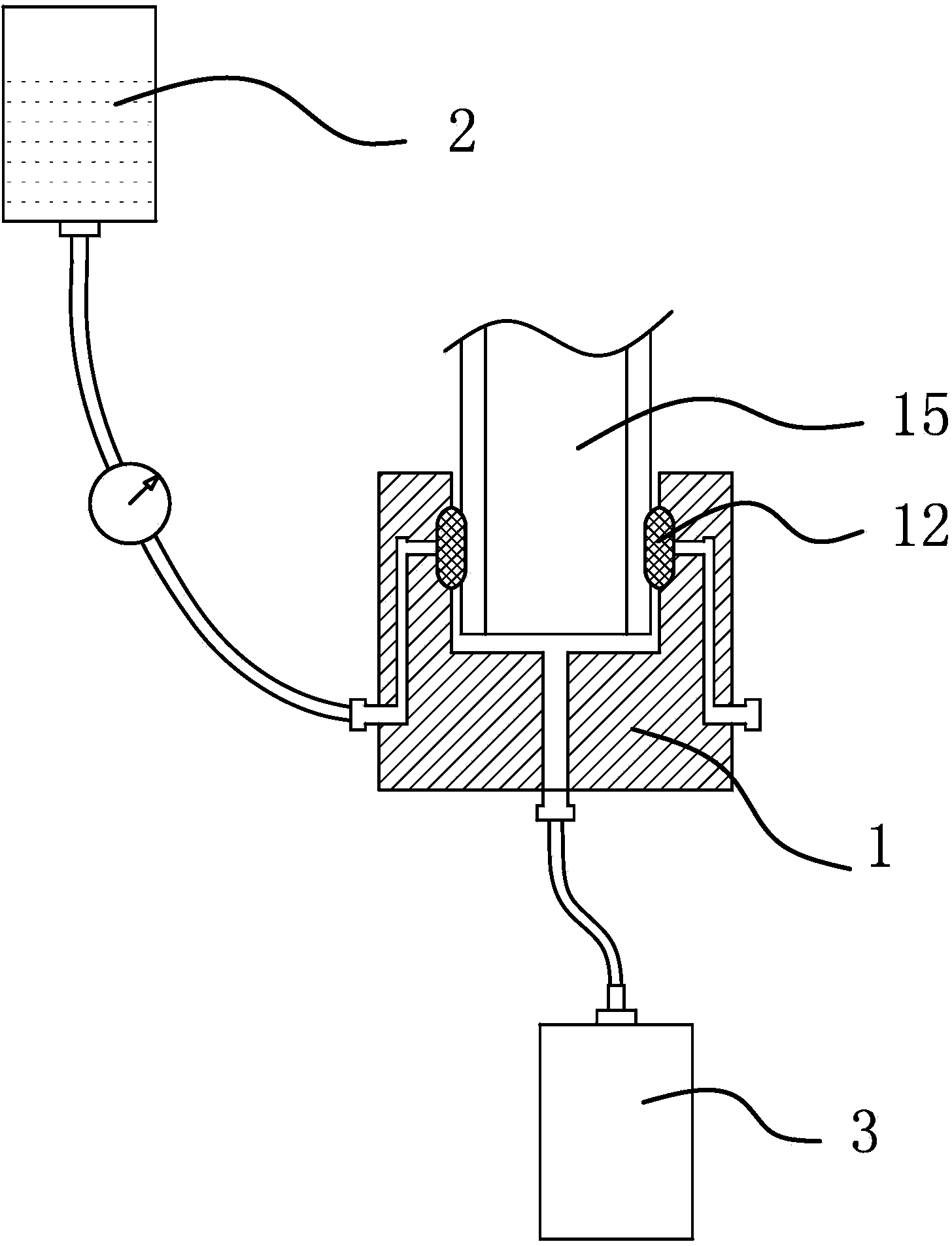

[0022] like figure 1 and figure 2 As shown, the gluing device includes a glue dispensing seat 1, a glue injection barrel 2 and a glue returning barrel 3. The glue dispensing seat 1 is provided with a concave cavity 4, and the concave cavity 4 has an opening 5 that can pass through the target workpiece 15. The concave cavity The inner surface of the 4 is also provided with a glue outlet 6, and the outer surface of the dispensing seat 1 is provided with a glue inlet 7. As a solution, the concave cavity 4 runs through the upper surface of the dispensing seat 1 and forms an opening 5, and the opening 5 is vertical. Straight upward, the inner surface of the concave cavity 4 is fixed with an annular dispensing ring 12, the dispensing ring 12 is made of a glue-absorbing material and can absorb and store glue, the dispensing ring 12 passes through the glue outlet 6, and when dispensing When the ring 12 is in contact with the target workpiece 15 , the glue dispensing ring 12 can coat...

Embodiment 2

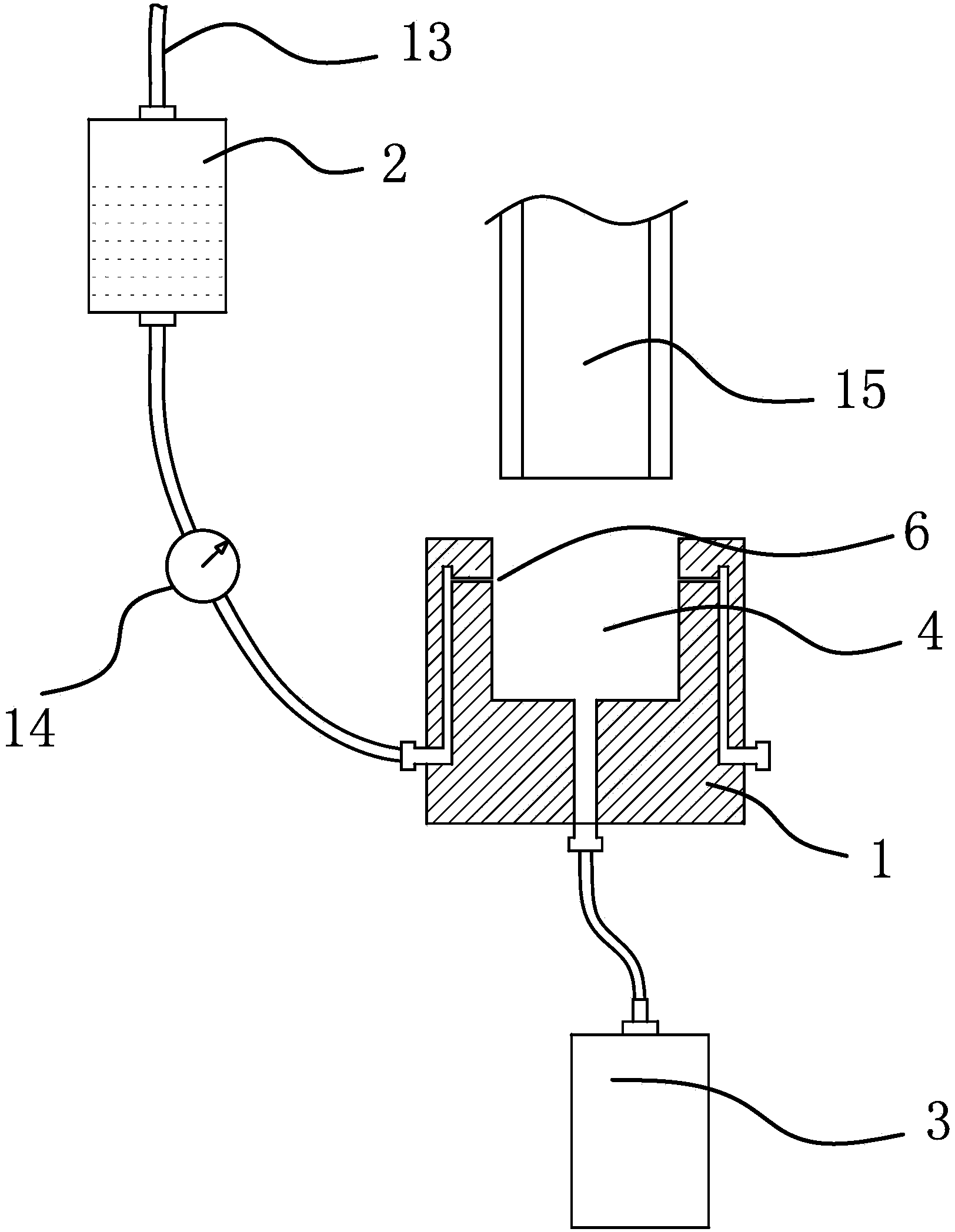

[0026] Such as image 3 and Figure 4 As shown, the general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the glue returning channel 10 is arranged along the vertical direction, and the entrance of the glue returning channel 10 is opened on the bottom surface of the concave cavity 4, The outlet of the glue returning channel 10 is set on the bottom surface of the glue dispensing seat 1 , and the glue returning barrel 3 is located under the glue dispensing seat 1 . The vertical setting of the glue returning channel 10 can improve the speed of glue returning, and the location distribution of the outlet and the inlet of the glue returning barrel 3 and the glue returning channel 10 makes the glue returning more thorough. As another solution, the concave cavity 4 runs through the upper end surface of the dispensing seat 1 and forms an opening 5, the opening 5 faces upwards vertically, the glue injection barrel 2 is a clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com