Mould machining method and system

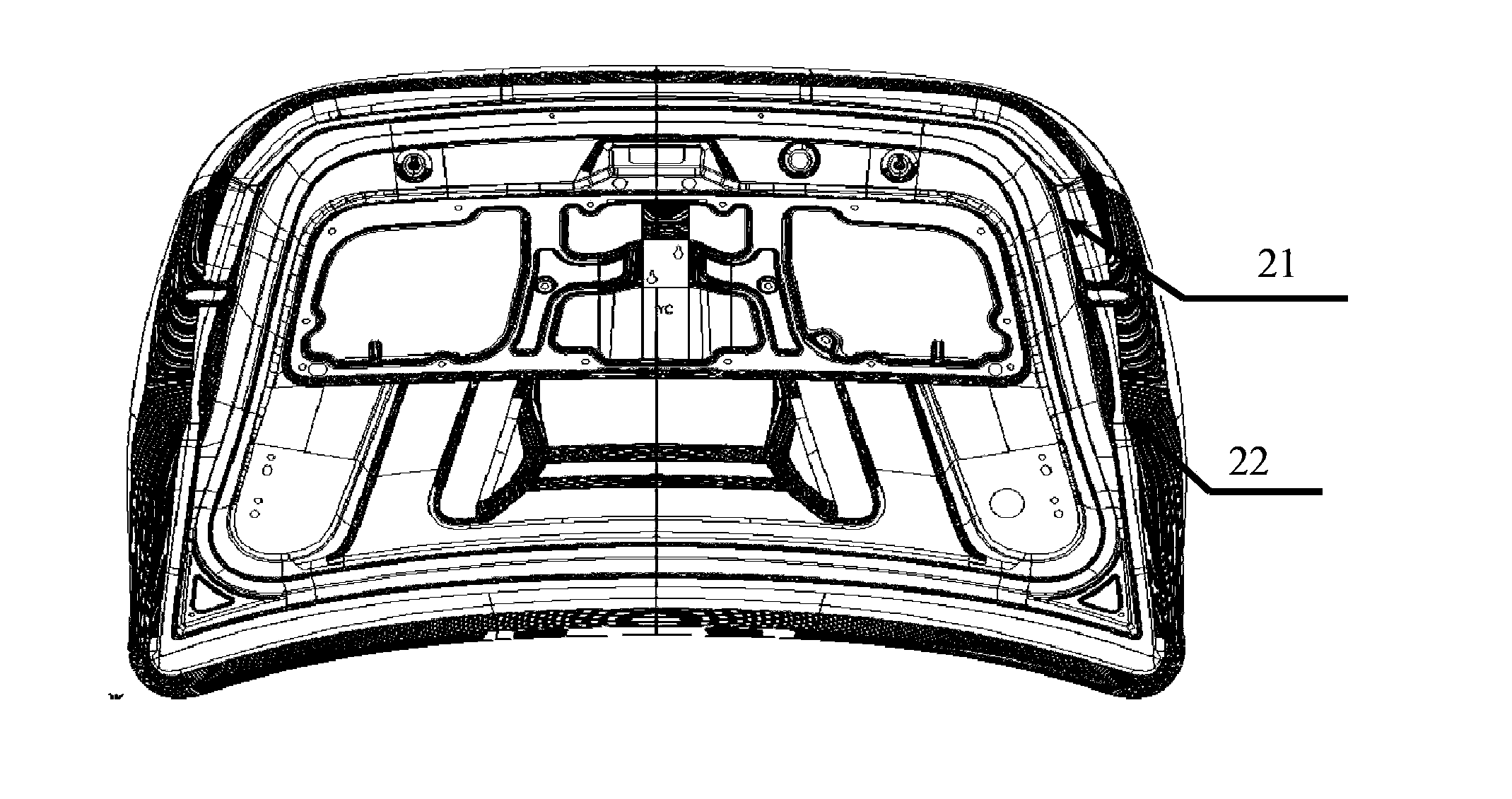

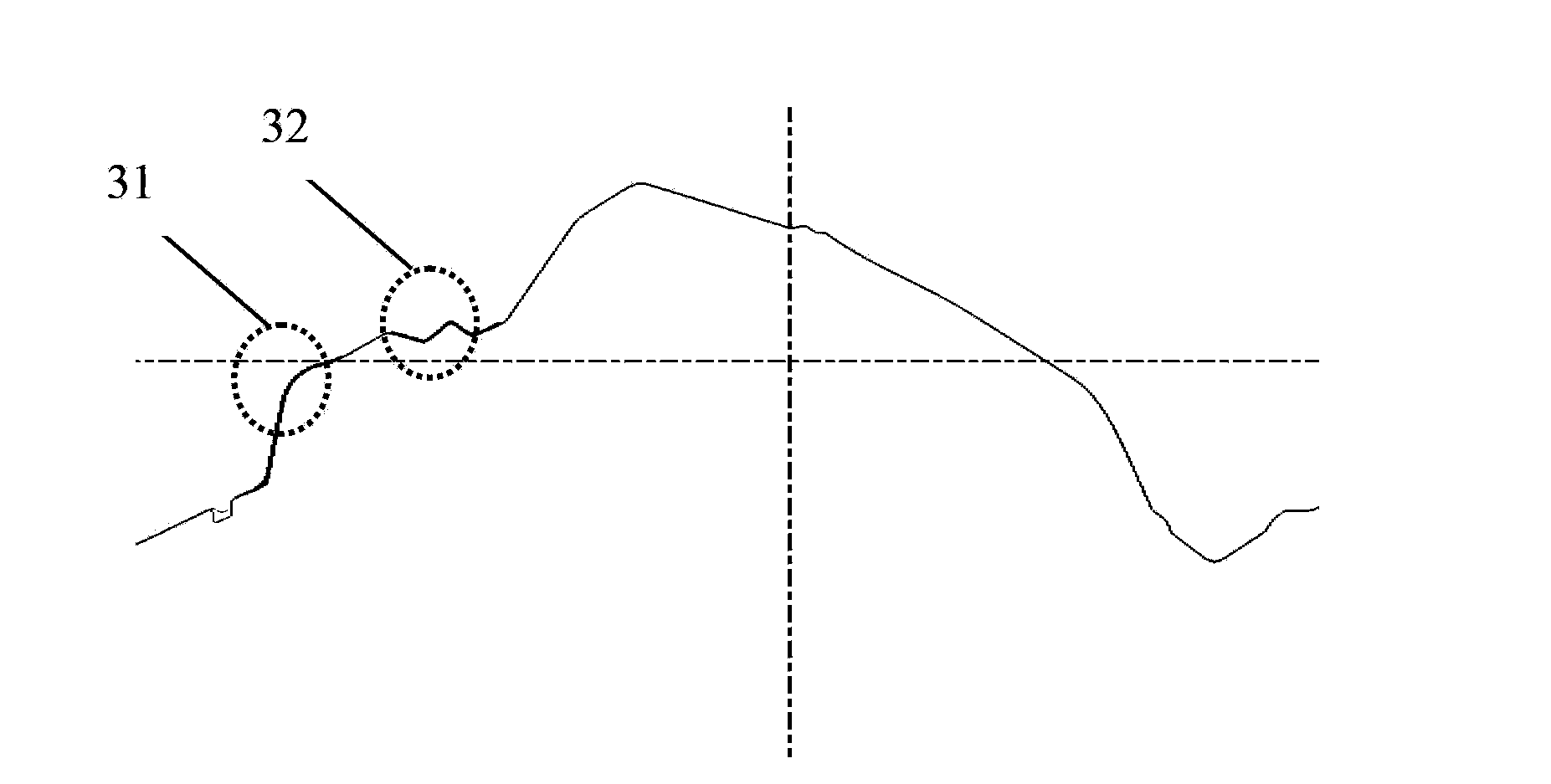

A mold processing and mold technology, which is applied in the field of mold processing methods and systems, can solve the problems of difficult to guarantee the precision and quality of stamping parts, inconsistent shape and small value of parts, etc., and achieve the effect of improving dimensional accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

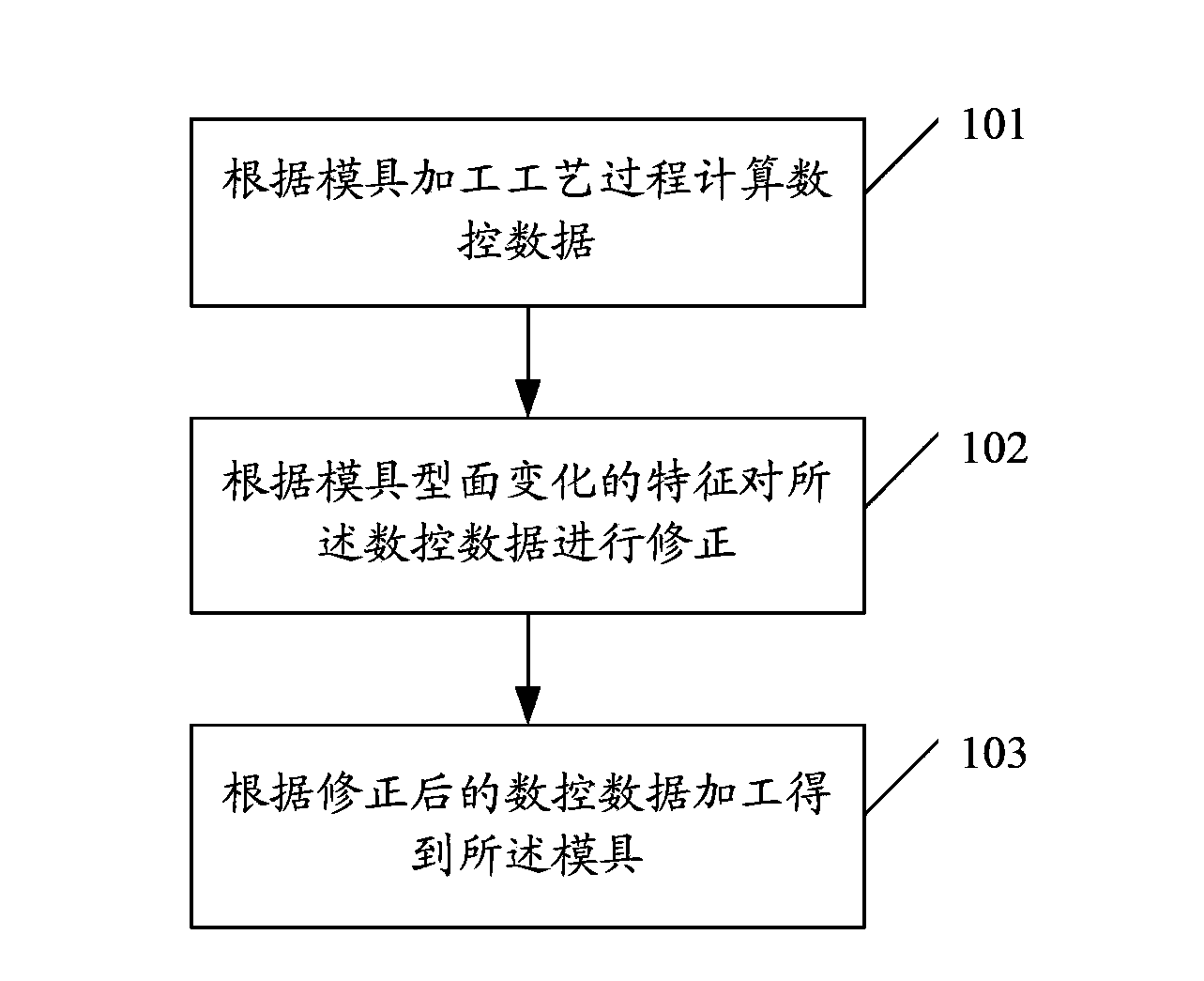

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0041] Numerical control is a method that uses digital signals to control the movement of machine tools and their machining processes. Numerical control machining is the technology of applying numerical control technology to traditional processing technology, using digital instructions composed of numbers, characters and symbols to realize the motion control technology of one or more mechanical equipment, which usually controls position, angle, speed, etc. Mechanical quantities and switching quantities related to the flow of mechanical energy. The advantages of CNC machining methods are mainly reflected in the following aspects: flexibility means good adaptability, high machining accuracy, ability to process com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com