How to use high-precision geometric shape milling cutter processing device

A geometric shape and processing device technology, applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve problems such as easy deformation, difficult pocket holes, difficult milling cutter processing, etc., and achieve the effect of ensuring shape and position tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

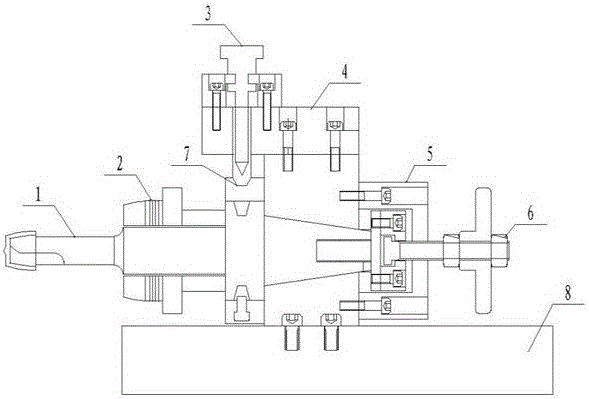

[0009] The following is based on figure 1 The structural diagram of the high-precision geometric shape milling cutter processing device shown is specifically explained as follows: the high-precision geometric shape milling cutter processing device, the milling cutter outer casing 2 is connected and fixed on the side positioning plate 5, and the milling cutter is rotated by the gear 7. Angle, axis The rotation positioning screw 3 is fixed on the upper positioning plate 4, the axial translation gap adjustment screw 6 is fixed on the side positioning plate 5, and the whole device is fixed on the wire cutting platform.

[0010] The method of using the high-precision geometric shape milling cutter processing device, first fix the milling cutter 1 on the milling cutter casing 2, rotate the angle of the milling cutter 1 through the gear 7, and when the angle is adjusted, axially rotate the positioning screw 3 to fix the gear 7 Then adjust the axial translation of the milling cutter 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap