A Plastic Forming Method for Small-sized Hollow and Thin-walled Shell Parts

A thin-walled shell and plastic forming technology, which is applied to weapon accessories, offensive equipment, ammunition, etc., can solve the problems of reducing product quality stability, difficult to control welding heat, and affecting fragment quality, so as to improve penetration resistance and Stability, achieve consistent control of organizational performance, good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

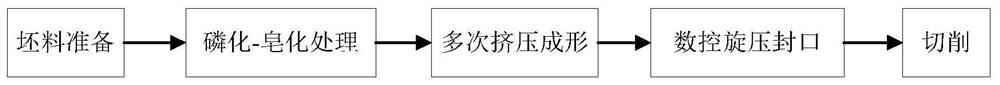

[0039] A plastic forming method for a small-sized hollow thin-walled casing, comprising the following steps:

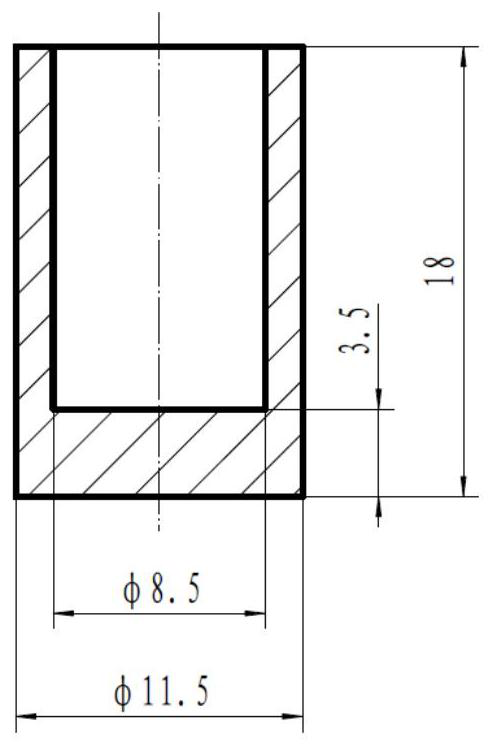

[0040] (1) Blank preparation: According to the forming part diagram of the hollow thin-walled shell part ( figure 2 ), calculate the volume of the material, and select the appropriate blank size according to the plastic forming theory and the principle of near-uniform plastic deformation, and cut the corresponding bar according to the principle of plastic forming volume invariance. The material grade is 20, and the diameter of the bar is φ12mm. A blank with a size of φ11.2×10.6 mm was prepared by turning. After I lubricant treatment, a lubricating layer is prepared on the surface of the billet.

[0041](2) Thin-walled shell by extrusion: put the billet obtained in step (1) into the cavity of the extrusion die, under the action of three-dimensional compressive stress and deformation rate of 10mm / s, after two passes of extrusion Compression deformation, the depth of ...

Embodiment 2

[0047] A plastic forming method for a small-sized hollow thin-walled casing, comprising the following steps:

[0048] (1) Blank preparation: Calculate the volume of the material according to the formed part diagram of the hollow thin-walled shell, and select the appropriate blank size according to the theory of plastic forming and the principle of near-uniform plastic deformation, and cut the corresponding blank according to the principle of constant volume in plastic forming. The bar, the material grade is 45, the diameter of the bar is φ12mm, and it is prepared into φ11.2×10.6mm through turning. After I lubricant treatment, a lubricating layer is prepared on the surface of the billet.

[0049] (2) Thin-walled shell by extrusion: put the billet obtained in step (1) into the cavity of the extrusion die, and under the action of three-dimensional compressive stress and deformation rate of 15mm / s, extrude through three passes. Compression deformation, the depth of the first extr...

Embodiment 3

[0055] A plastic forming method for a small-sized hollow thin-walled casing, comprising the following steps:

[0056] (1) Blank preparation: Calculate the volume of the material according to the formed part diagram of the hollow thin-walled shell, and select the appropriate blank size according to the theory of plastic forming and the principle of near-uniform plastic deformation, and cut the corresponding blank according to the principle of constant volume in plastic forming. The bar, the material grade is 921A, the diameter of the bar is φ12mm, and it is prepared by turning to φ11.2×10.6mm. After I lubricant treatment, a lubricating layer is prepared on the surface of the billet.

[0057] (2) Thin-walled shell by extrusion: put the billet obtained in step (1) into the cavity of the extrusion die, and under the action of three-dimensional compressive stress and deformation rate of 20 mm / s, extrude through 4 passes Compression deformation, the first extrusion cavity depth is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com