A CNC five-axis tenon processing machine tool

A technology for processing machine tools and tenons, which is applied in tenon making devices, making tenon or tenon grooves, etc., can solve problems such as inaccurate positioning, long replacement time, complex structure, etc., and achieve processing technical problems, high processing accuracy, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

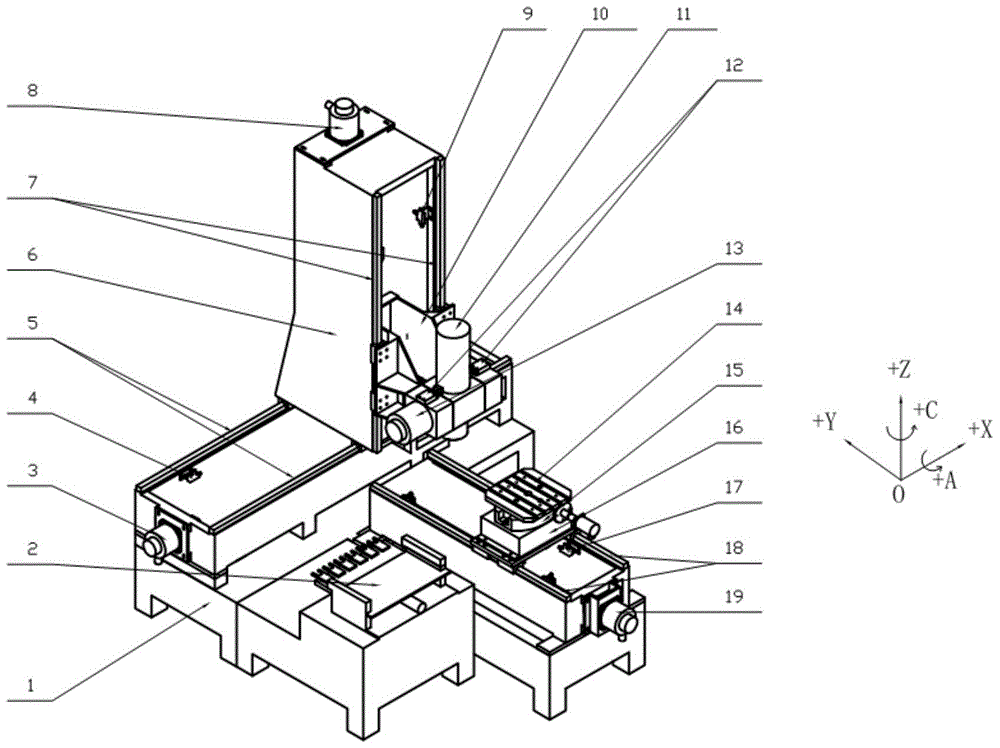

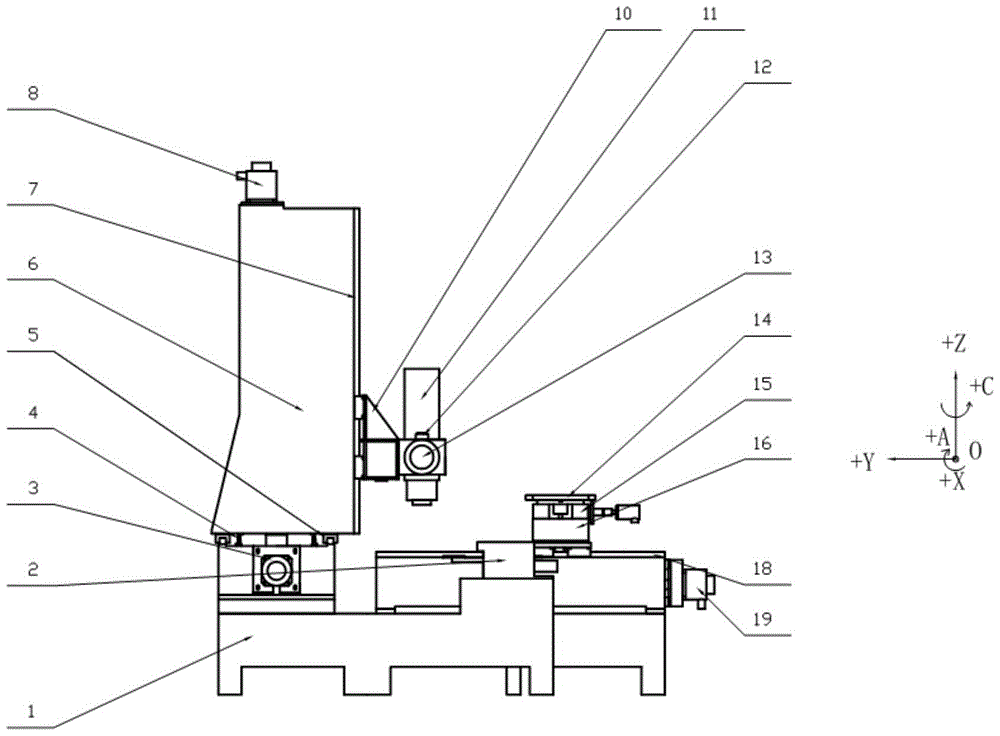

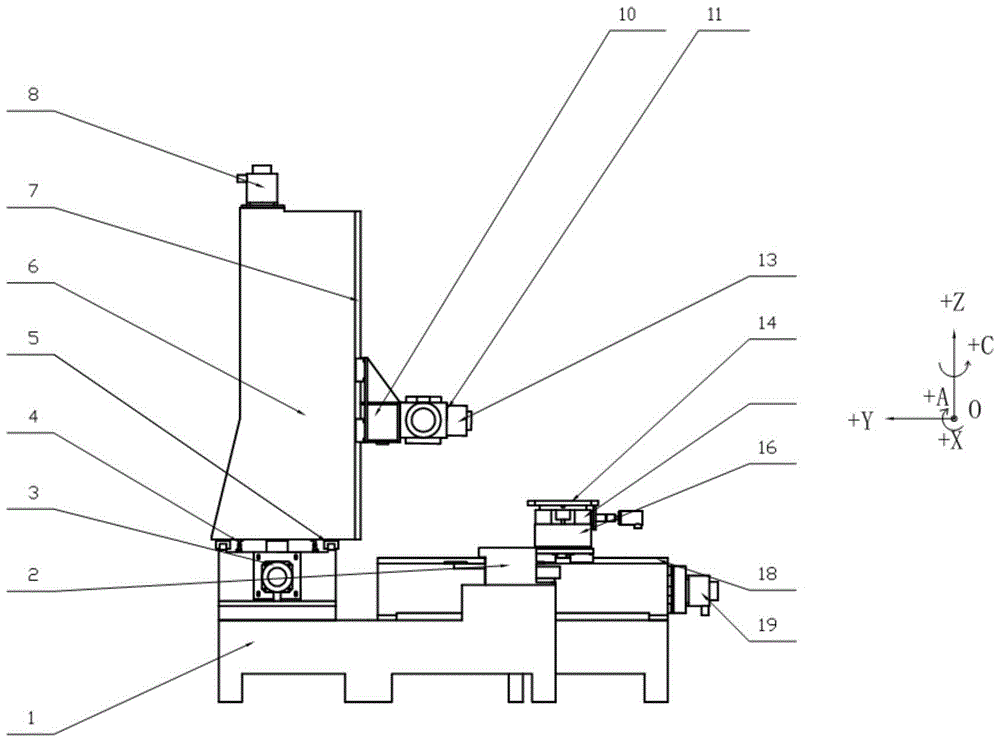

[0011] in figure 1 , figure 2 , image 3 Middle: The bed 1 is a welded structure with a guide rail seat on it, an X-direction guide rail 5 is provided on the guide rail seat, a column part 6 is placed on the X-direction guide rail, and a spindle part 10 with a vertical sliding table is placed on the column part 6. The spindle component 10 is equipped with an electric spindle 11, and the spindle vertical-horizontal conversion is controlled through the spindle vertical-horizontal locking device 12 and the spindle vertical-horizontal conversion motor 13. A Y-direction slide 16 is placed on another pair of Y-direction guide rails 18 of the bed, and a rotary positioning turntable 15 and a rectangular work surface 14 are placed on the bed. The turntable is controlled by a semi-closed loop to reciprocate along the Y direction on the bed. Rotation positioning state can be horizontal and axial rotation. The workpiece is clamped on the worktable surface 14 through the fixture, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap