A hexagonal tool post for a CNC five-axis tenon processing machine tool

A technology for processing machine tools and hexagonal tool rests, which is used in dovetail tenon processing, wood processing appliances, manufacturing tools, etc. It can solve the problems of inability to meet mass production requirements, inability to complete tenon processing, and reduce tool change time. Manpower, strong practicability, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

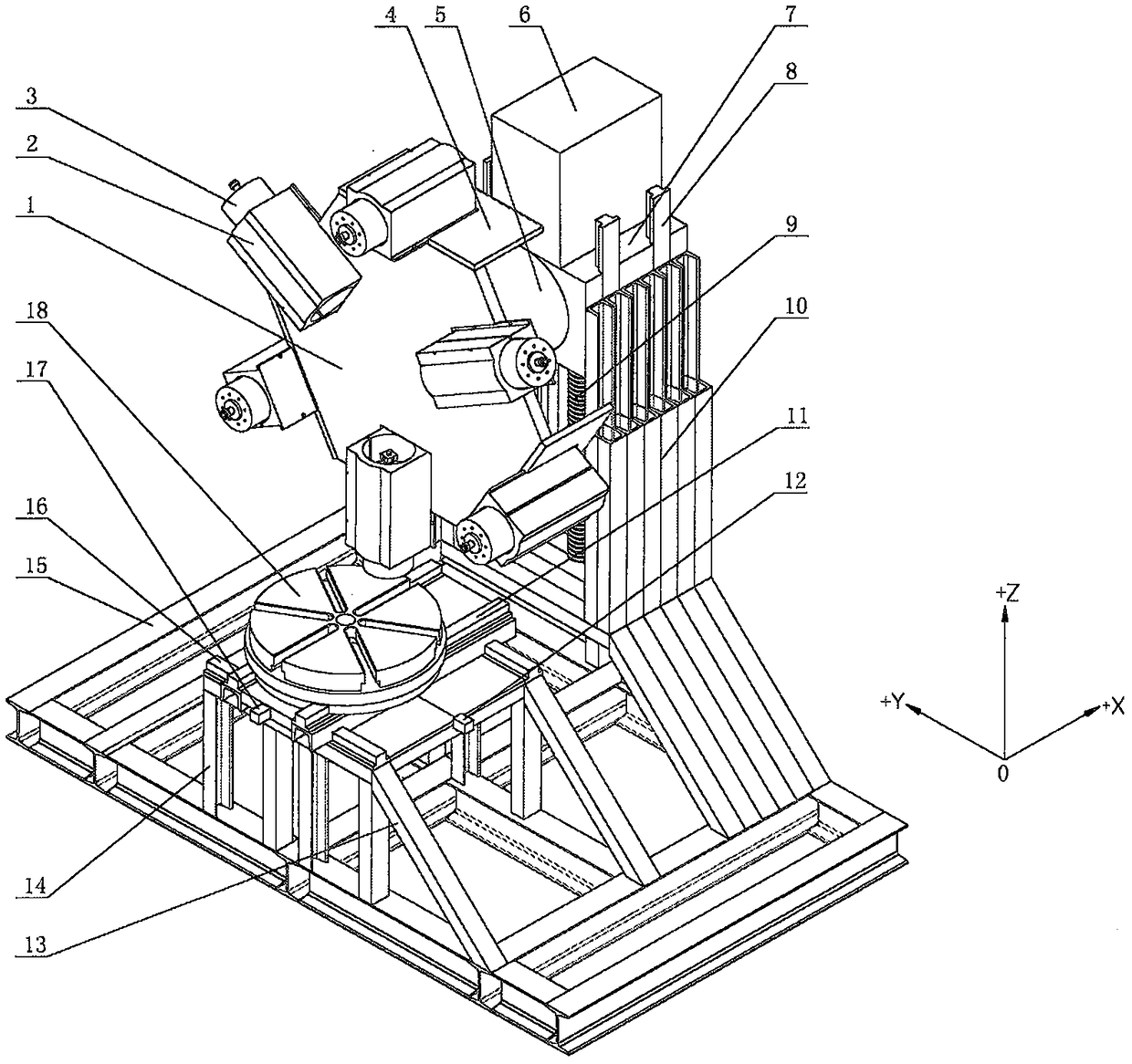

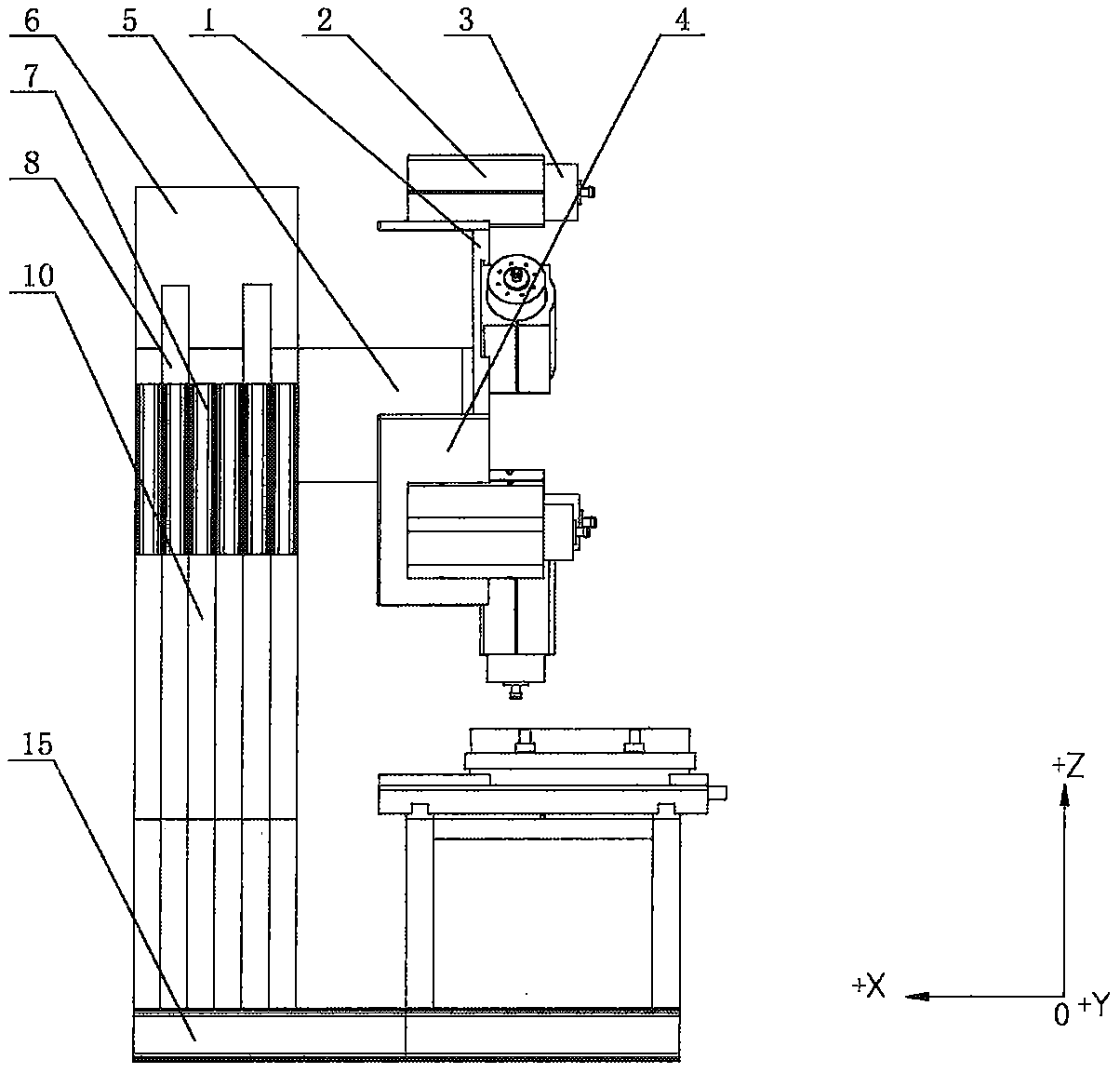

[0016] exist figure 1 , figure 2 Middle: The spindle part 2 of the hexagonal tool post is fixedly connected to the tool post body 1, and the tool is clamped on the electric spindle 3; the spindle part 2 is installed alternately on the axial and radial edges of the tool post body 1, and the axial spindle part The tool head faces the negative direction of the X axis, and the tool head on the radial spindle part 2 is radially outward; the axially installed spindle part 2 is installed on the support plate 4, and the positive direction of the X axis of the tool holder body 1 passes through the roller Part 5 is connected to the slide rail 7 of the CNC five-axis tenon processing machine tool, and the hexagonal tool post is driven by the driving device of the roller part 5 to achieve 0 to 360-degree rotation, thereby realizing the tool change and end milling of the tool on the electric spindle 3 relative to the workpiece and horizontal milling conversion.

[0017] CNC five-axis ten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap