A method for expanding a quartz tube and a special blowtorch device

A quartz tube and quartz technology, applied in the field of quartz tube expansion method and special blowtorch device, can solve the problems of low tube expansion efficiency, uneven tube wall thickness, poor tube expansion effect, etc., to increase air contact Opportunity, guaranteed wall thickness uniformity, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

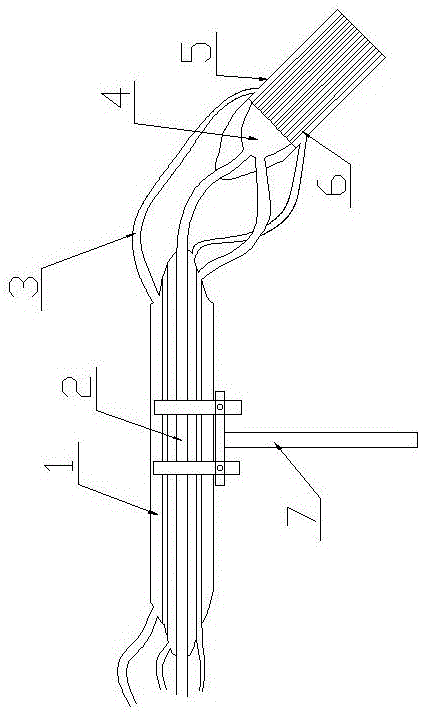

[0011] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0012] refer to figure 1 , a quartz tube expansion method, first install the quartz mother tube on the left and right clamps of the tube expander, start the blowtorch device on the middle tray device of the tube expander, and at the same time the left and right clamps rotate synchronously to drive the quartz mother tube to rotate, the speed The temperature is 500~1200 rpm. While rotating, the quartz mother tube is partially heated, and the heating temperature is kept at 1700°C-1800°C. The heated part of the quartz mother tube becomes semi-molten, and the centrifugal force generated by the rotation of the semi-fused quartz mother tube It expands outward under the action, and is shaped under the action of the tube expansion suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com