Non-pickling tanning method for production of bovine leather

A technology of tanning and pickling, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, chemical treatment before tanning, etc. effect of action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Tanning process of cow head layer

[0030] 1. Deliming and softening: According to the characteristics of the product, low-temperature softening enzyme is used for softening treatment. Rotation) time is 60 to 90 minutes (20 to 60 minutes longer than the softening time of conventional low temperature softening enzymes). Requirements: The temperature is normal temperature, the deashing should be thoroughly, and the pH value of the bath liquid should be measured at 8.0 to 8.5. The rotating speed of the drum is the same as the existing technological requirements.

[0031] 2. Non-pickled chrome tanning:

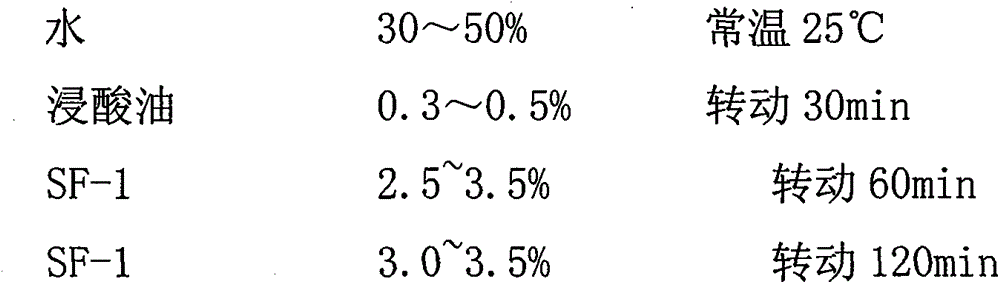

[0032] Add 30% of normal temperature water (about 25°C) to the tanning drum, and then proceed in sequence:

[0033] Add pickling oil 0.3~0.5% and rotate for 20min

[0034] Add SF-12.5~3.5% and rotate for 60min

[0035] Add SF-12.5~3.5% and rotate for 120min

[0036] The incision inspection requires full penetration, and the pH value of the bath solution ...

Embodiment 2

[0041] Embodiment 2: cattle two-layer tanning process

[0042] 1. Deliming and softening: According to the characteristics of the product, softening treatment is carried out by using low temperature softening enzyme. The dosage of softening enzyme is 0.6-1.2% of the tare weight (increased by 0-0.5% compared with the conventional dosage), and the dosage of the degreasing agent is the tare weight. 0.3 ~ 0.8% (conventional cowhide processing degreasing operation is carried out in the stage of soaking, liming or retanning, while the non-pickling chrome tanning technology is used for tanning cattle two-layer leather, because the two-layer leather contains high oil and fat, In order to avoid the presence of oils and fats at high pH, an additional step is added to produce chrome soap after adding the unpickled chrome tanning agent). The rotation time of the softening drum is 60 to 90 minutes (30 to 60 minutes longer than the conventional time). Requirements: The temperature is nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com