Processing method for sheared sheep skin leather

A processing method, sheep shearing technology, applied in the field of leather processing, can solve the problems of limited raw materials, uneven wool density, unsuitable processing, etc., and achieve the effect of not easy to fall down, good hand feeling, and uniform wool density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

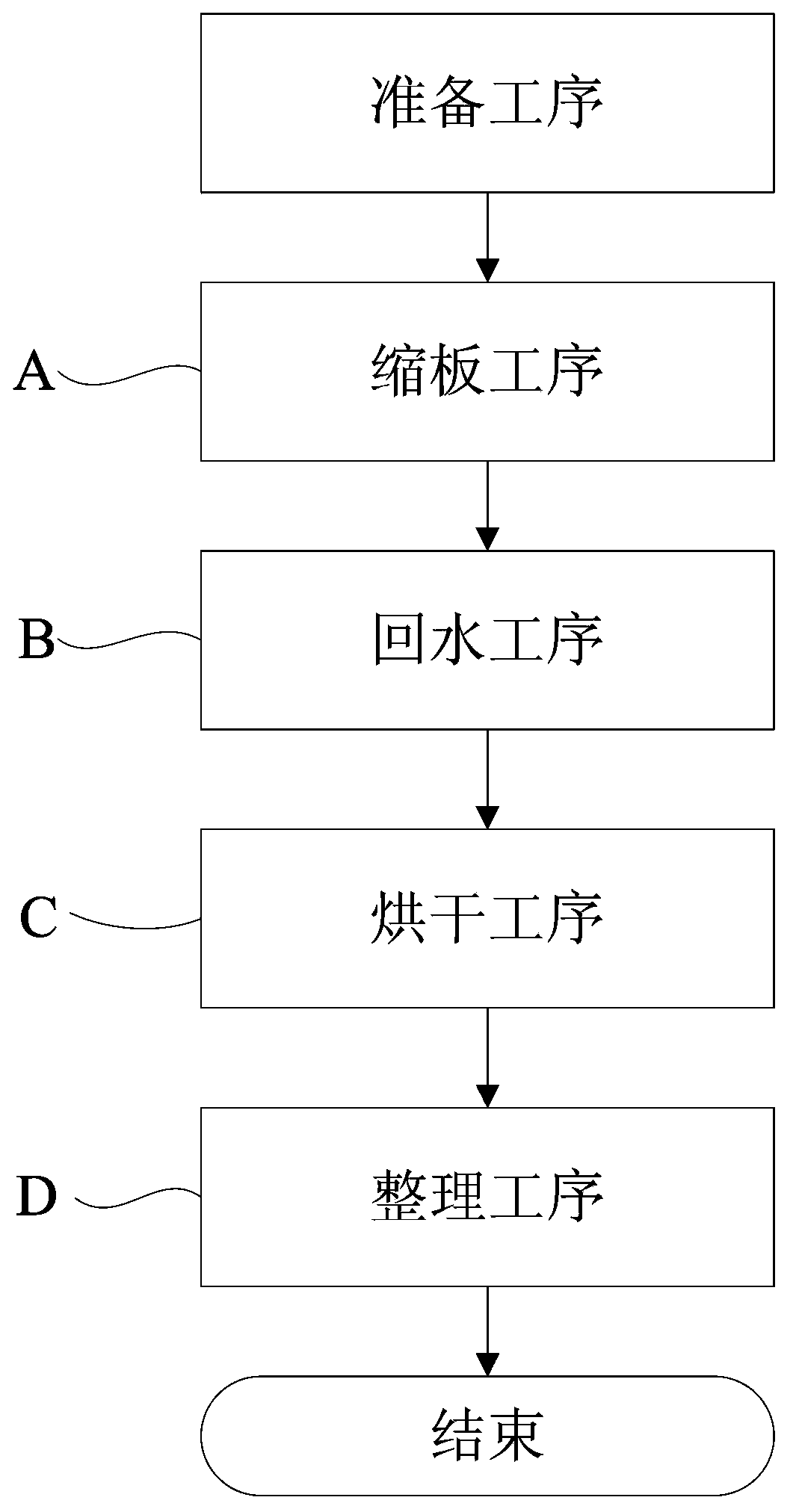

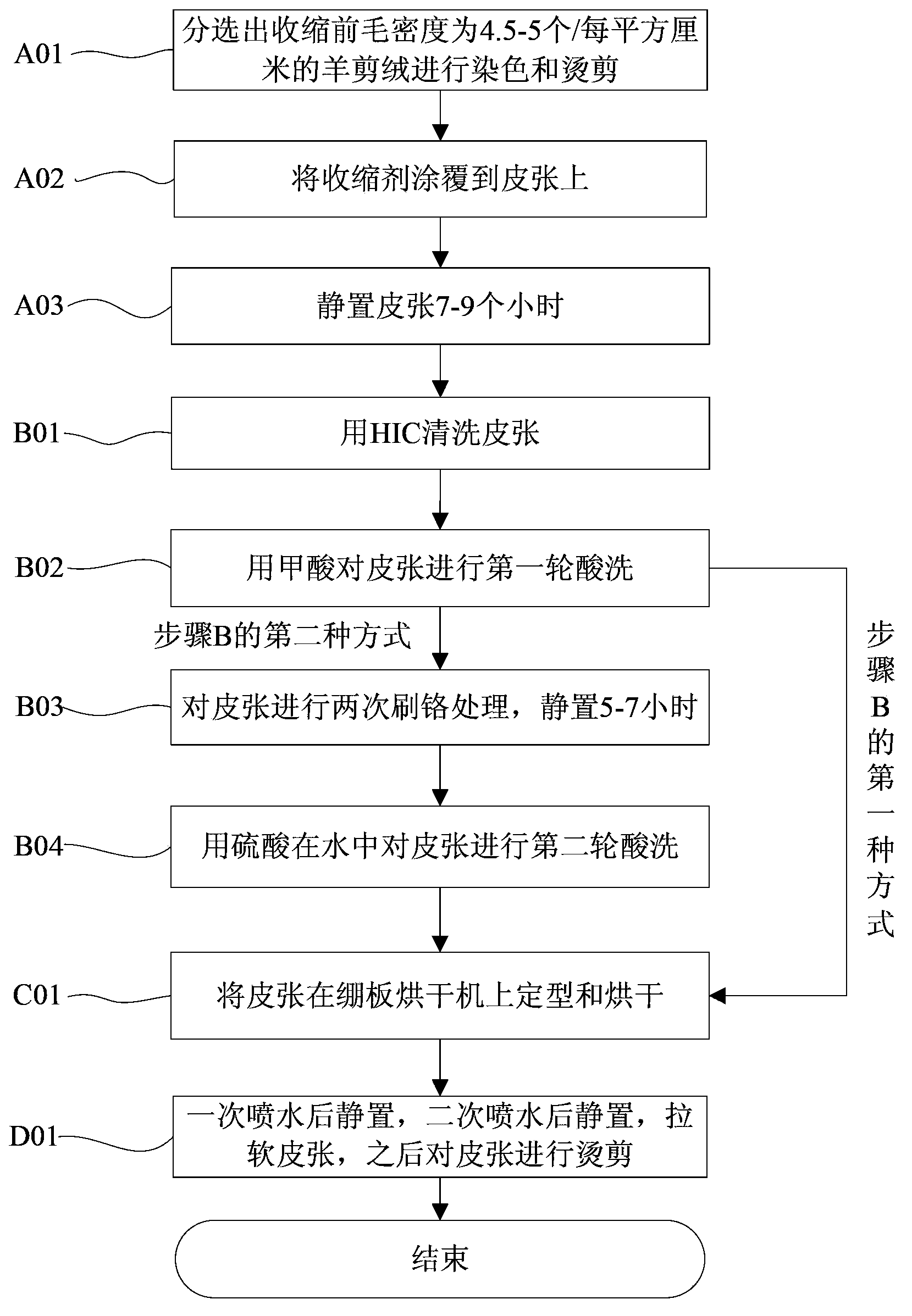

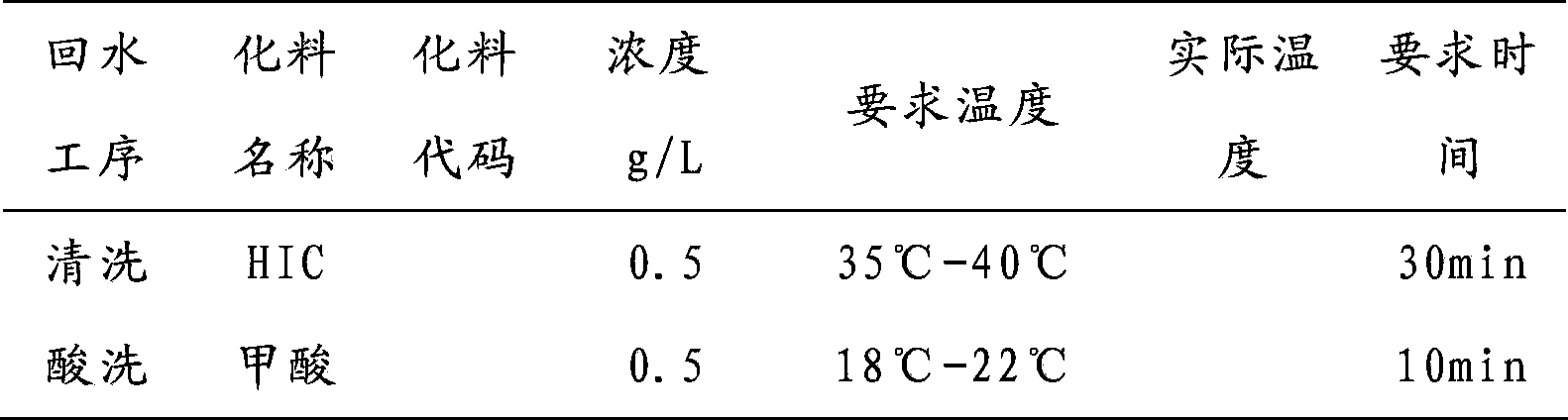

Method used

Image

Examples

Embodiment approach

[0052] In the first embodiment, in order to obtain sheep shearling products with a wool density of 5 pieces / cm2, in step A02, it is only necessary to apply the shrinkage agent to the hide once.

[0053] In the second embodiment, in order to obtain sheep shearling products with a gross density of 5.5-6 pieces / cm2, in step A02, the shrinkage agent needs to be applied to the hide twice.

[0054] In the third embodiment, in order to obtain sheep shearing products with a gross density of 6-7 pieces / cm2, in step A02, the shrinkage agent needs to be applied to the hide three times.

[0055] In the fourth embodiment, in order to obtain sheep shearling products with a wool density of 7 pieces / cm2 or more, in step A02, the shrinkage agent needs to be applied to the hide four times.

[0056] Step A02 is further optimized, the rotating speed of the roller is 10-10.5r / min, and the speed of the roller coater is 10-10.5r / min.

[0057]Step A03, put each skin on the skin board, place the skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com