X-shaped T-shaped connecting component and manufacturing process thereof

A technology for manufacturing technology and connectors, which is applied in the field of T-shaped connectors and its manufacturing technology, can solve the problems of energy consumption and poor economy, and achieve the effect of improving ductility and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

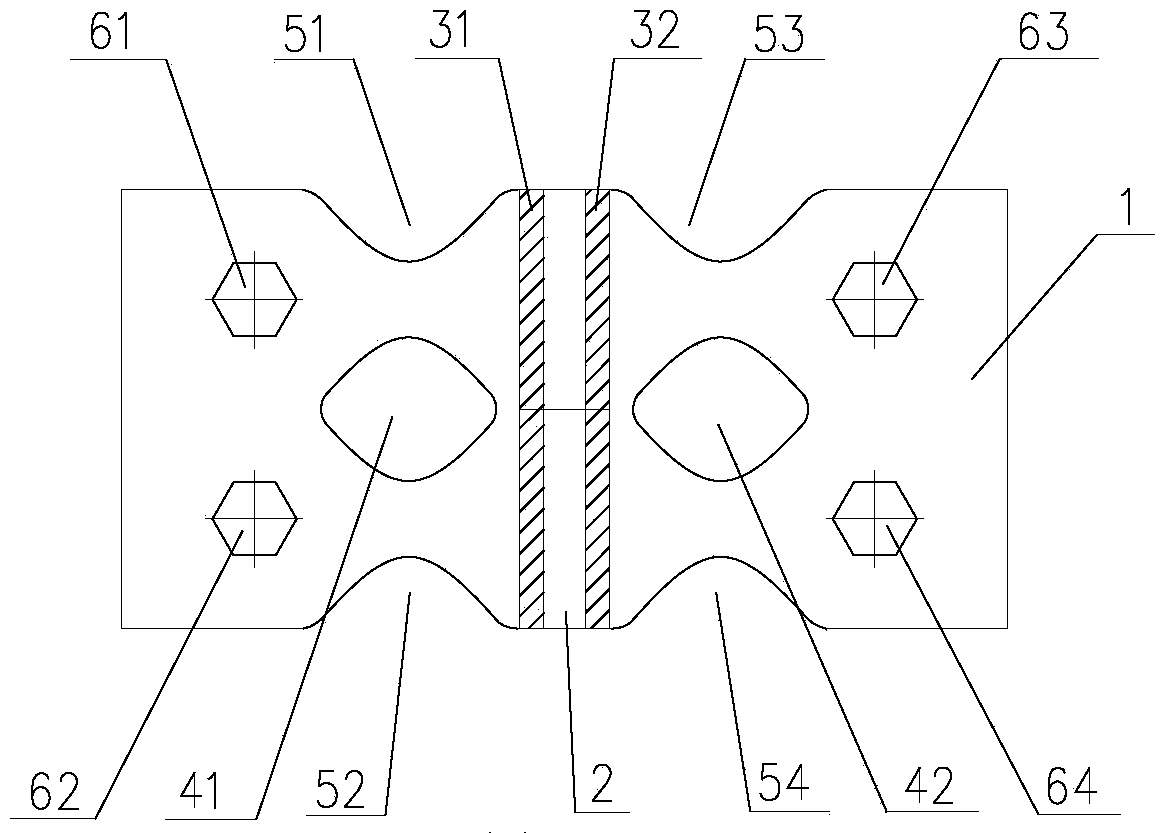

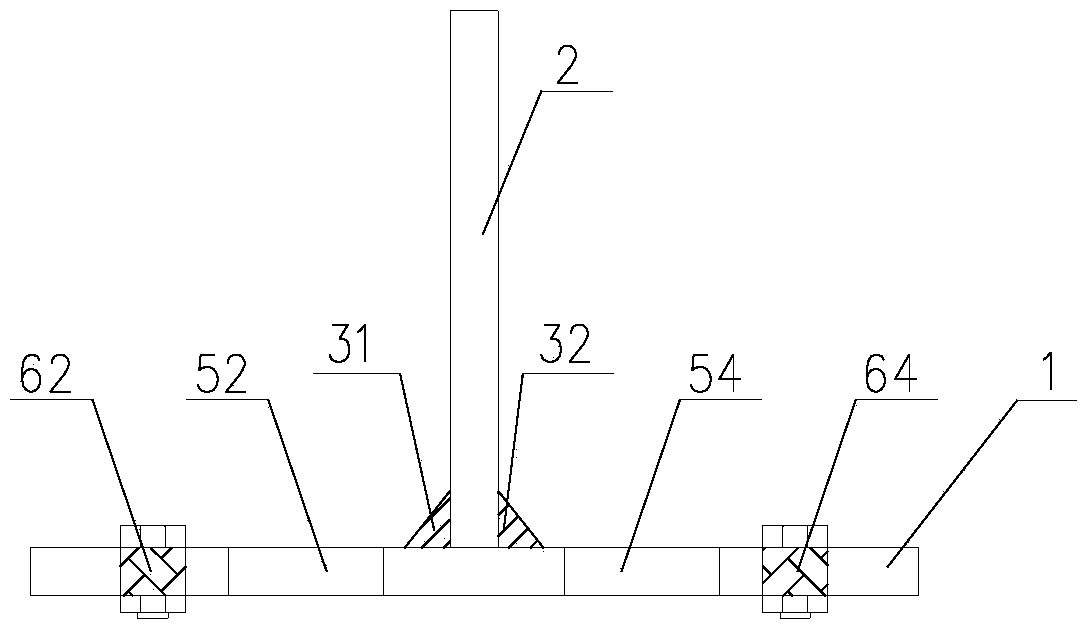

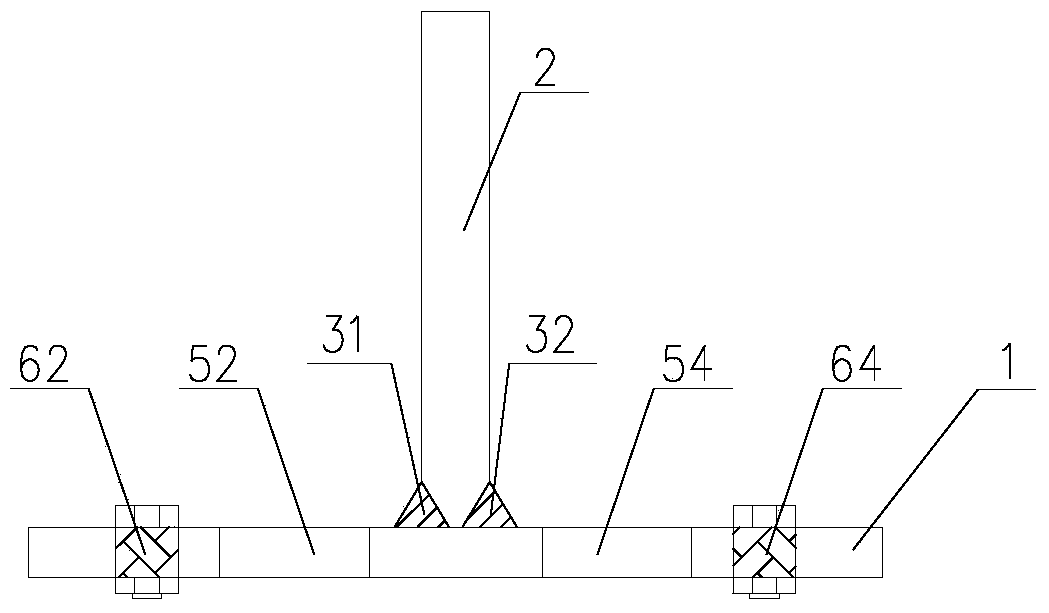

[0040] refer to figure 1 and Figure 4 , an X-shaped T-shaped connector, including a rectangular web 2, and an X-shaped flange plate 1, the X-shaped flange plate 1 is provided with a long axis of symmetry and a short axis of symmetry, and the X-shaped flange plate Bolt holes are provided on both sides of 1, and the bolt holes are arranged symmetrically around the long axis of symmetry, and the rectangular web 2 is fixedly installed on the long symmetry axis of the X-shaped flange plate 1, and the X There are 2n energy-dissipating holes in the rectangular flange plate 1, n is a positive integer, and they are arranged symmetrically in pairs with the long symmetry axis as the center, and the n energy-dissipating holes on the same side of the rectangular web 2 are symmetrically arranged with the The axis is arranged at the center, and the cross-sectional outer contour of the energy-dissipating hole is a closed curve with continuous smooth transition;

[0041] The energy dissipat...

Embodiment 2

[0051] refer to Figure 5 , a manufacturing process of an X-shaped T-shaped connector as claimed in claim 1, said manufacturing process comprising the steps of:

[0052] The first step, select the rectangular steel plate as the rectangular web 2, and then select the rectangular steel plate as the blank of the X-shaped flange plate 1;

[0053] The second step is to open 2n energy-dissipating holes on the blank of the X-shaped flange plate 1, n is a positive integer, and the X-shaped flange plate is provided with a long axis of symmetry and a short axis of symmetry, and the X-shaped flange plate Bolt holes are provided on both sides of the rectangular web, and the bolt holes are arranged symmetrically with the long axis of symmetry as the center. The short axis of symmetry is arranged at the center, and the cross-sectional outer contour of the energy-dissipating hole is a closed curve with continuous smooth transition;

[0054] The energy dissipation hole is located between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com