Method and device for mechanized workover rod and pipe straightening guide to remove and hang rings

A technology of operating rods and lifting rings, which is applied in the direction of drill pipes, drill pipes, casings, etc., can solve the problems of dense auxiliary devices, small righting distance, and large investment, and achieve the effect of convenient operation, large righting distance, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

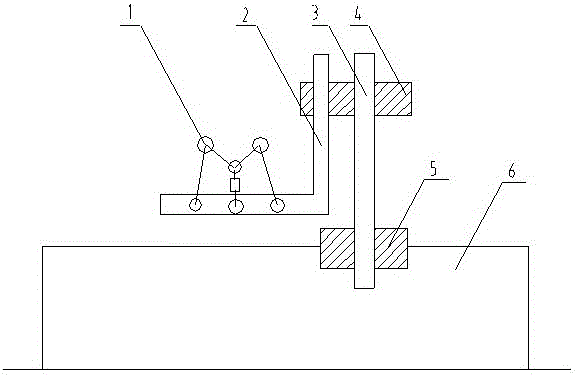

[0019] according to figure 1 As shown, the lower end of the support column 3 of the rod tube straightening guides the hanging ring device to be fixed on the wellhead platform 6 through the lower rotating device 5, and the curved arm 2 is installed on the supporting column 3 through the upper rotating device 4, and the lifting ring and the righting rod tube are removed and hung. The mechanism 1 is installed on the crank arm 2 . It can replace human beings on the wellhead platform to complete the guiding and straightening rods and pipes, reach from the wellhead to the top of the wellhead and align the thread or make the rods and pipes reach the wellsite from the wellhead, and can replace people to complete the work of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com