Pneumatic vane motor with rolling pairs

A technology of air motor and rolling pair, which is applied in the direction of rotating or oscillating piston engines, engine components, machines/engines, etc. It can solve the problems of reducing the conversion efficiency of air motors, wear of blades and inner walls of cylinders, etc., and achieves simple structure, small changes, The effect of increasing conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

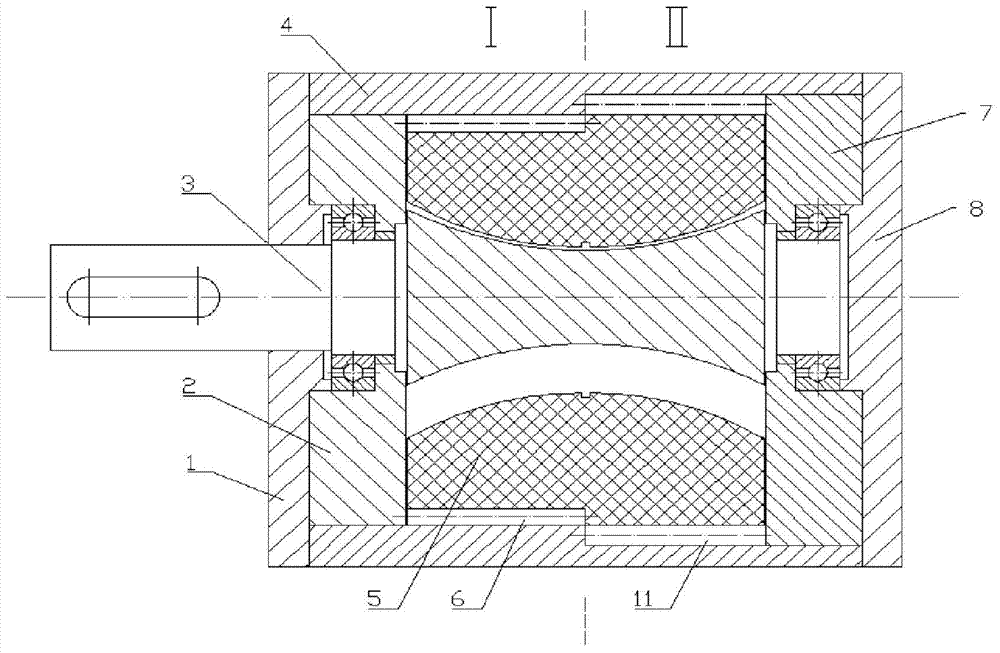

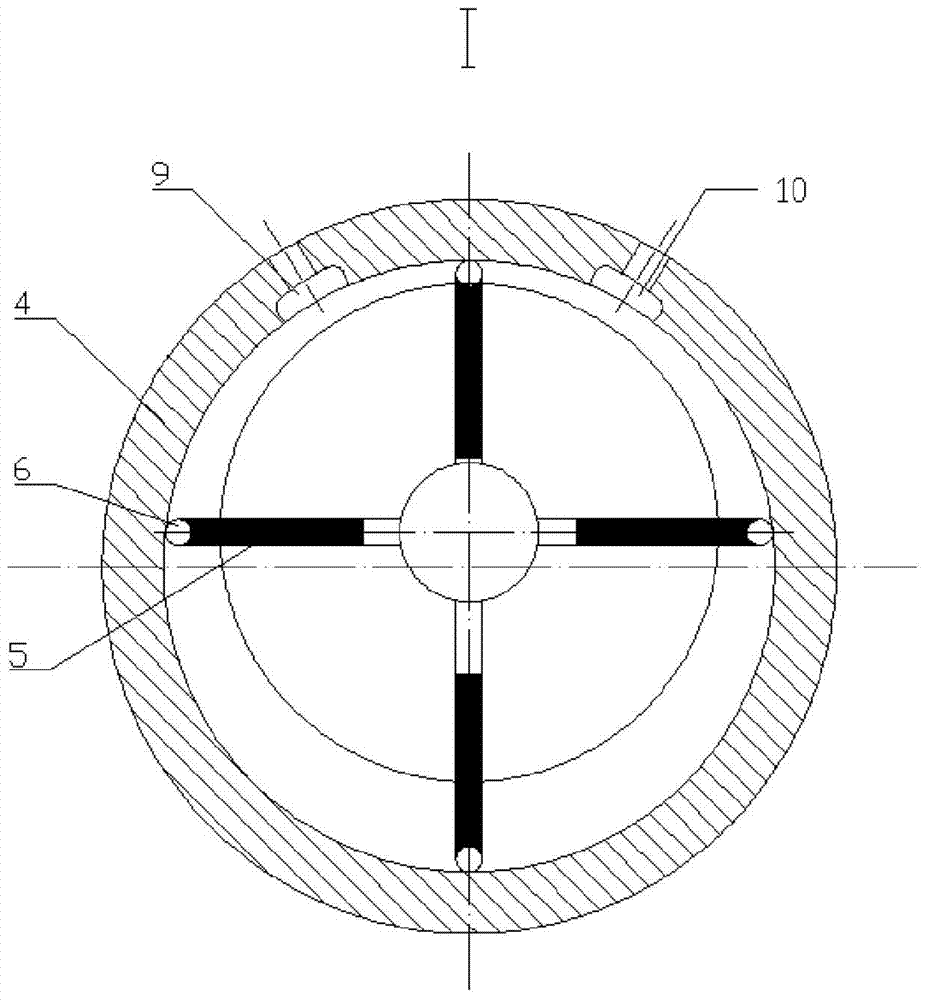

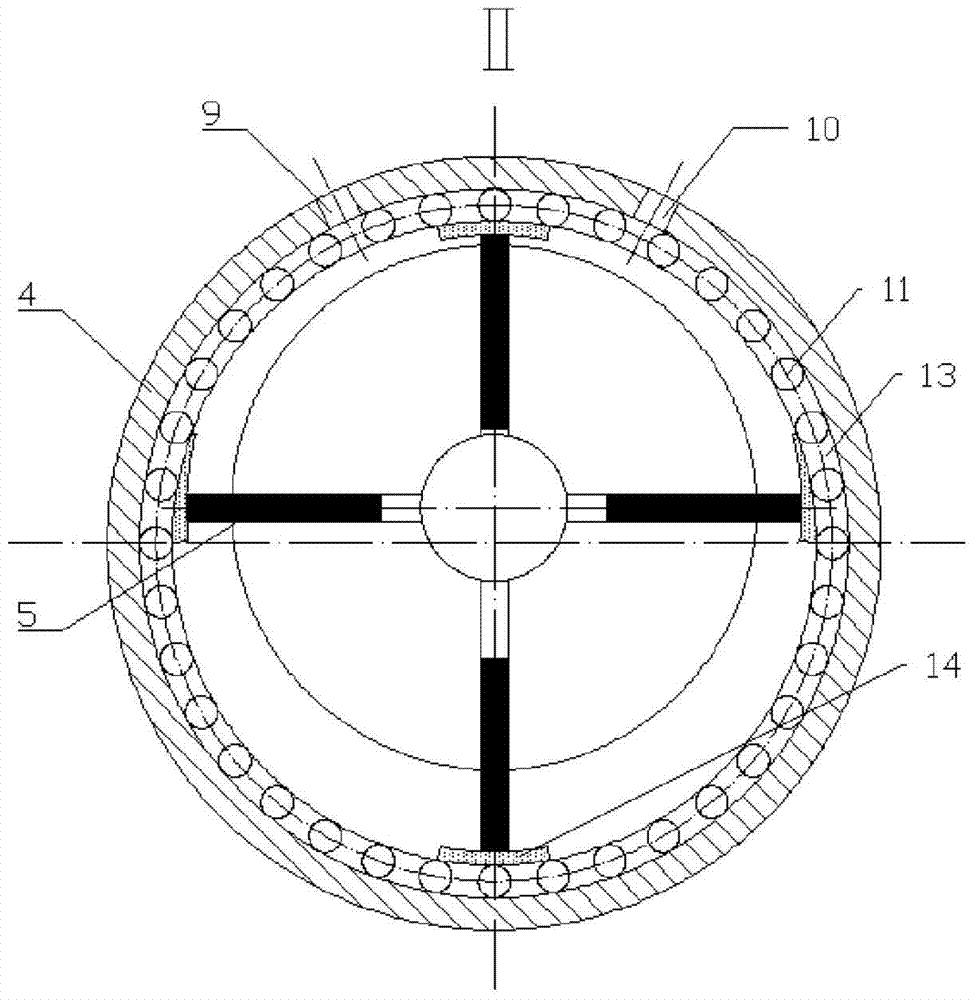

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0017] see figure 1 , figure 2 , image 3 and Figure 4 , the embodiment of the present invention comprises:

[0018] The vane type air motor with rolling pair is mainly composed of front cover 1, rear cover 8, front cover 2, rear end cover 7, rotor 3, cylinder 4, vane 5, air intake hole 9, exhaust hole 10, vane The end rolling pair I and the cylinder inner wall rolling pair II are composed; the cylinder 4 has two air guide holes, one is the air intake hole 9, and the other is the exhaust hole 10. The two air guide holes are symmetrically arranged, and can be connected through the external Change and exchange the functions of the two air gui...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap