Oil supply mechanism of linear compressor

A linear compressor and oil supply technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of unreliable structure and poor oil supply effect, so as to achieve reliable operation and ensure oil supply effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

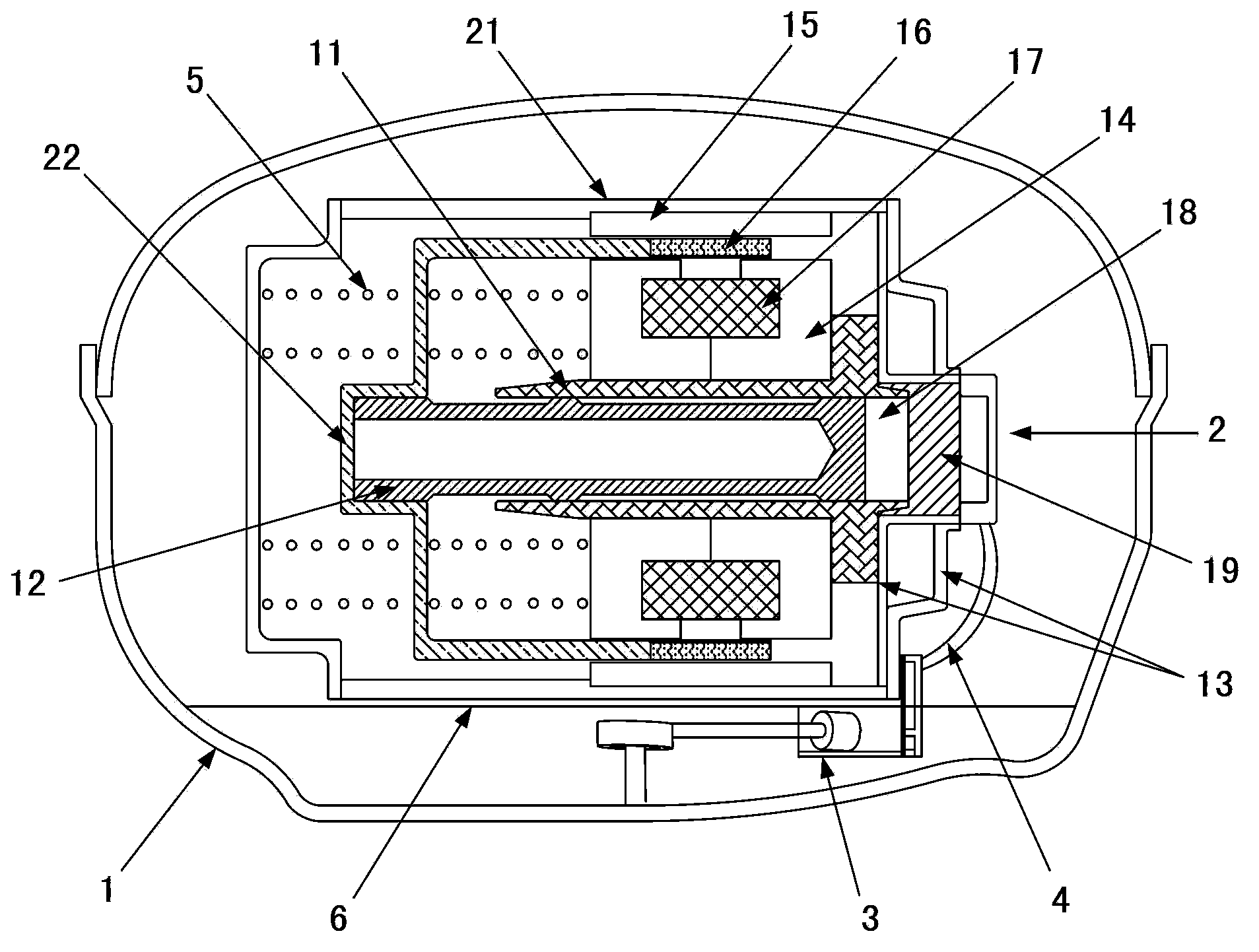

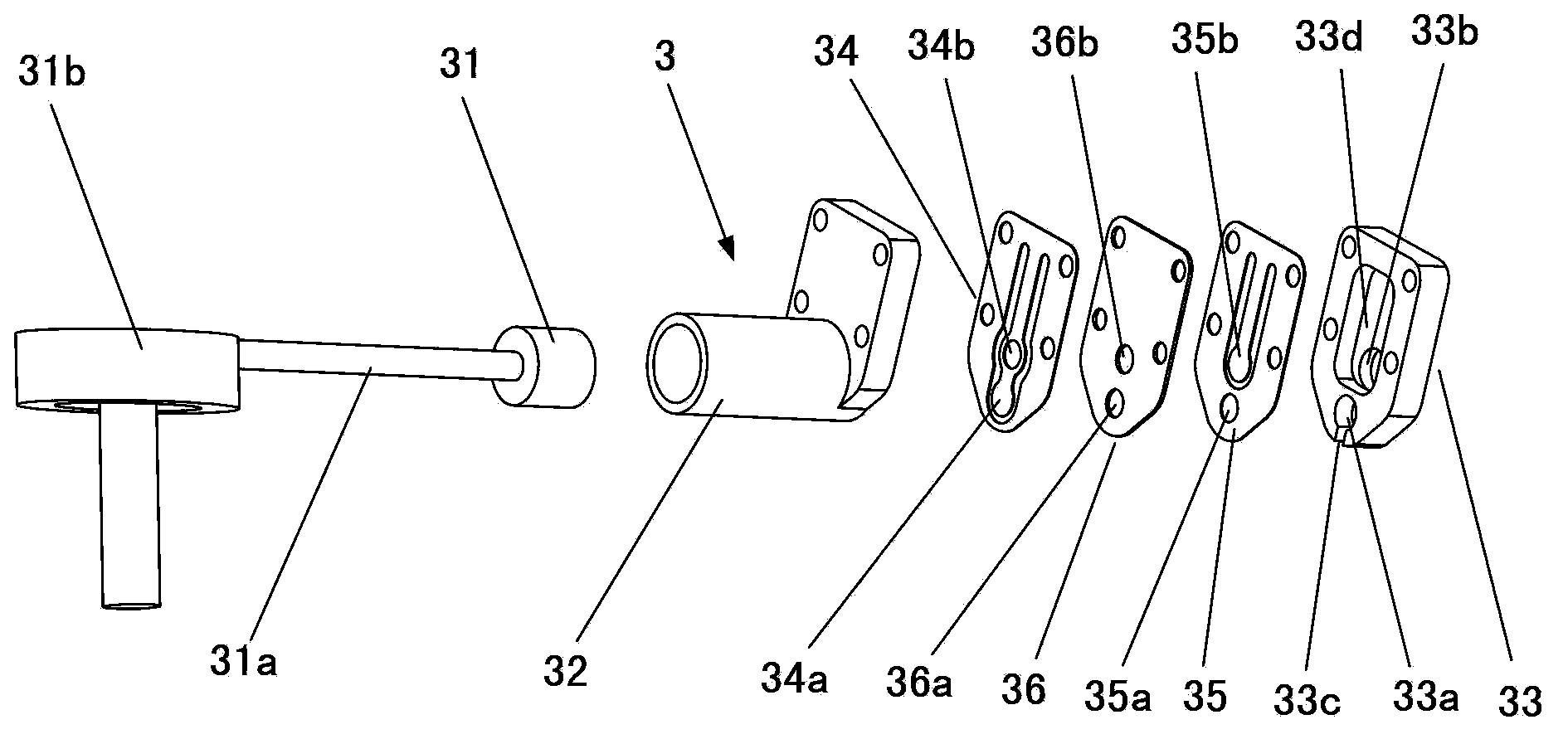

[0018] Refer below figure 1 and figure 2 The specific implementation of the oil supply mechanism of the linear compressor of the present invention will be described in detail.

[0019] Such as figure 1 As shown, the linear compressor has a casing 1 , and a motor body 2 and an oil supply mechanism 3 are accommodated in the casing 1 . A recess is formed at the bottom of the housing 1, and lubricating oil is stored in the recess, and symbol 6 in the figure indicates the liquid level of the lubricating oil. The oil supply mechanism 3 is connected to the motor body 2 through an oil supply pipe 4 to deliver lubricating oil to the motor body 2 . The motor body 2 has a housing 21 , and the housing 21 is supported on the inner wall of the housing 1 by a plurality of springs. The casing 21 is provided with a cylinder 11, a piston 12, a compression chamber 18, an exhaust valve 19, an inner stator 14, a coil 17 placed in the inner stator 14, an outer stator 15, a mover 16 and a mover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com