A miniature rolling rotor compressor

A rolling rotor and compressor technology, which is applied to machines/engines, liquid fuel engines, rotary piston machines, etc., can solve the problem that the exhaust valve plate and the exhaust hole are not tightly fitted, the deformation recovery ability is weakened, and the compressor is affected. Efficiency and other issues, to achieve the effect of tight fit, reduce exhaust noise, and prevent gas backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

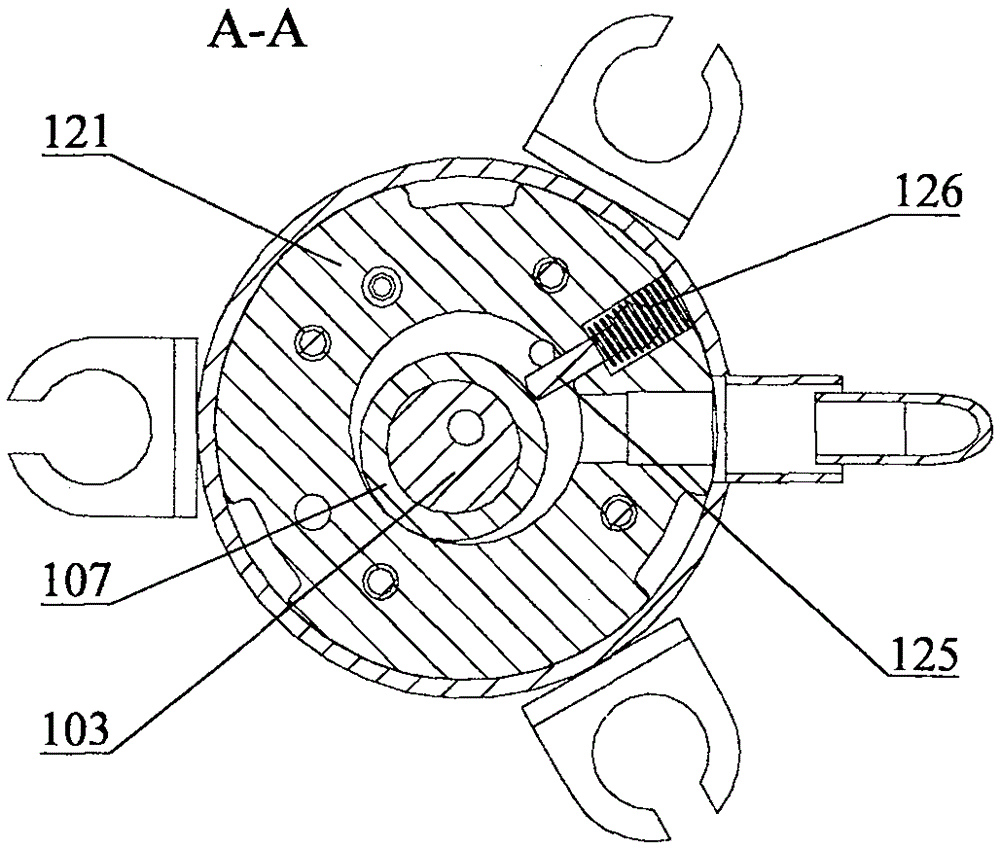

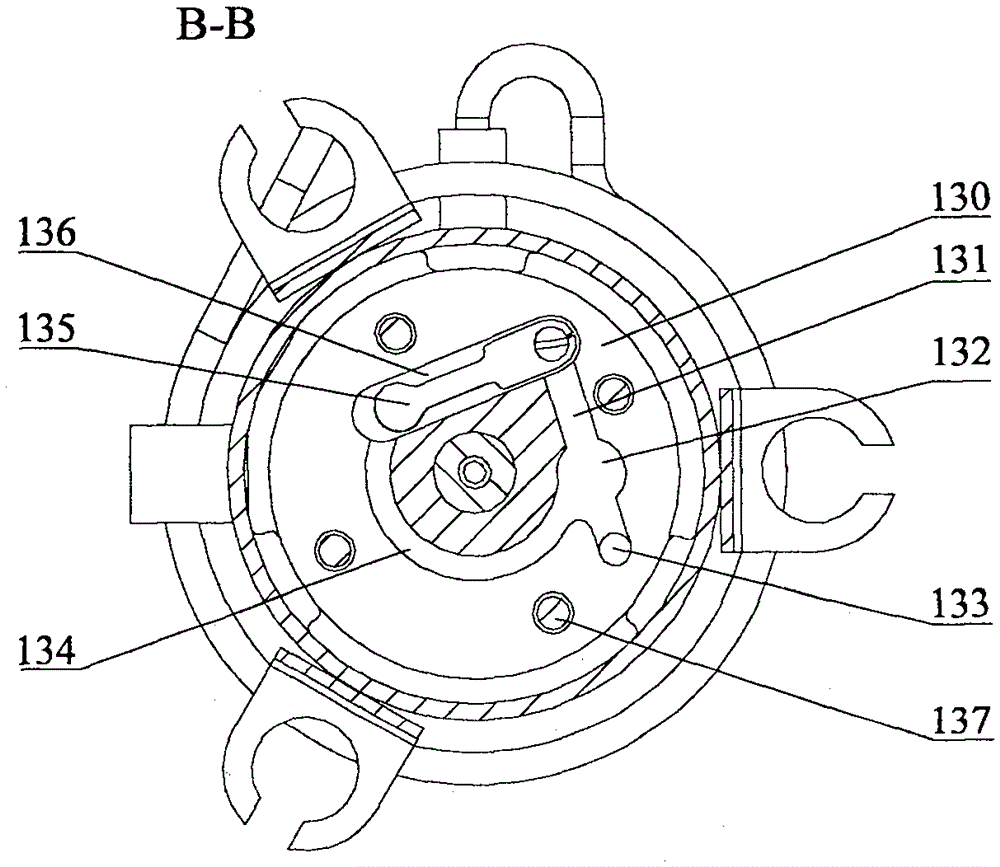

[0026] Such as Figure 1-3 A specific embodiment of a miniature rolling rotor compressor is provided as shown, the compressor includes: a motor 101 and a cylinder; the cylinder includes: a cylinder body 121, an upper flange 105, a cylinder head 130, and an exhaust baffle 111 , the piston 107 sleeved on the rotating shaft 103 and the vane 125, the vane 125 is fixed on the cylinder body 121 by a spring.

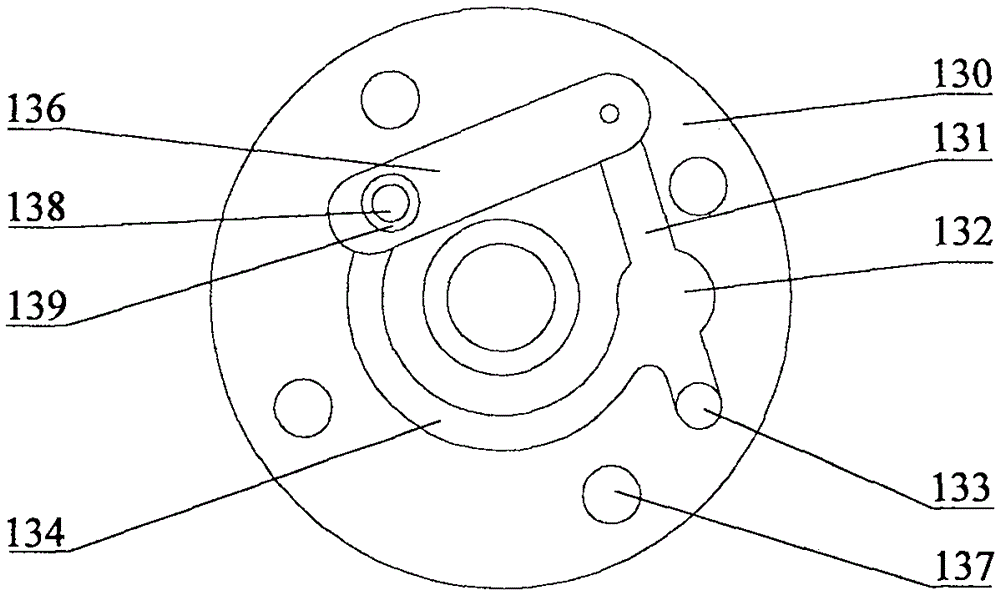

[0027] combine Figure 3-5 As shown, the cylinder head 130 is provided with: a first exhaust hole 133 , a second exhaust hole 138 , an exhaust groove and an exhaust valve plate 135 . Wherein, the exhaust groove is composed of a first exhaust groove 131, a second exhaust groove 134 and an exhaust valve plate installation groove 136, and the second exhaust hole 138 is arranged at one end of the exhaust valve plate installation groove 136 The exhaust valve plate 135 is fixed to the other end of the exhaust valve plate mounting groove 136 by screws, and the exhaust valve plate 13...

Embodiment 2

[0031] Such as Figure 6 As shown, the difference from Embodiment 1 is that in this embodiment, the second exhaust groove 134 is also provided with a sound-absorbing resonant cavity 1322, which can be a semicircular or square structure, and a circular structure Then it has better gas flow, and the cavity communicates with the second exhaust groove 134 . In the compressor, since the discharged gas is pulsating, that is, high pressure and low pressure alternately change, this will cause exhaust noise. However, the present embodiment is provided with a noise-eliminating resonant cavity 1322, which can absorb part of the gas into the cavity when the exhaust pressure is high, and the high-pressure gas stored in the cavity can release a part of the gas when the exhaust pressure is low. division. In this way, due to the gas storage function of the cavity, the high and low pressure difference of the pressure pulsation of the discharged gas is reduced, so that the exhaust noise can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com