Alignment method of laser alignment device under the control point of theodolite

A technology of laser centering and theodolite, which is applied in theodolite, active optical measuring device, measuring device, etc., can solve the problems of low precision and limited selection of measurement control points, and achieve the effect of improving precision and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

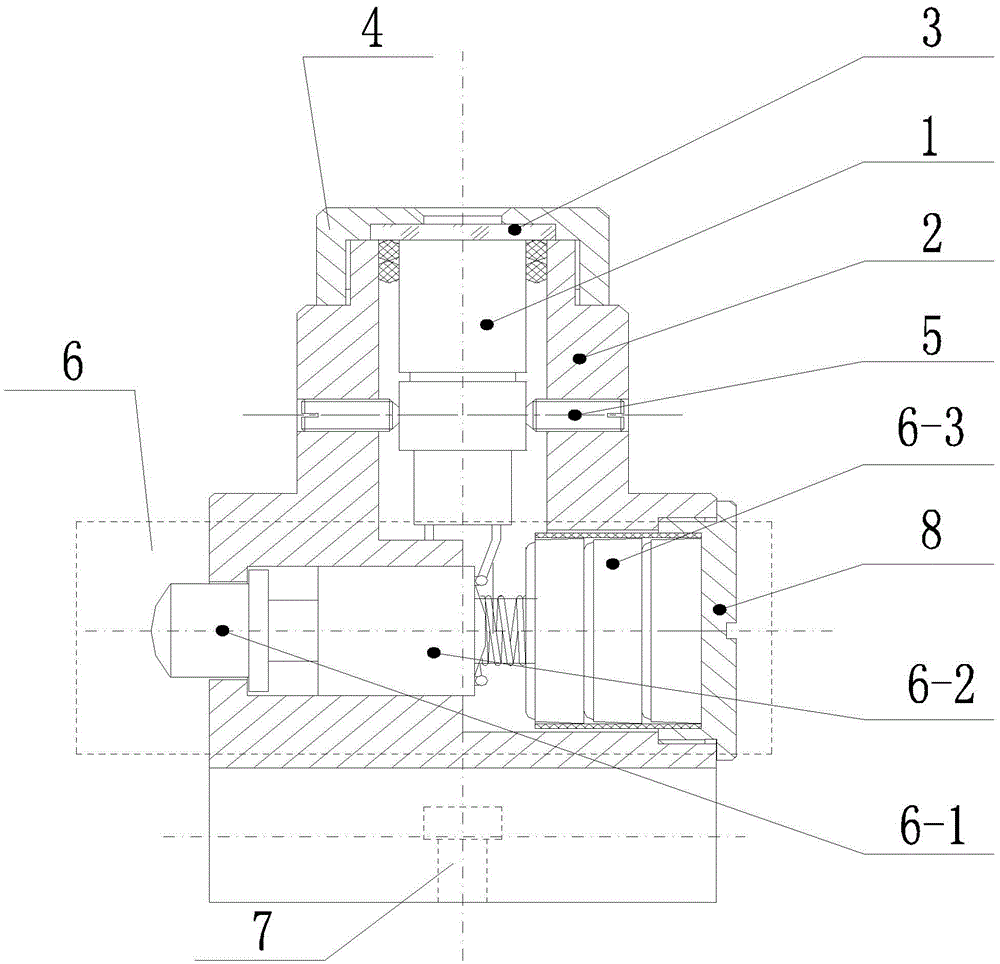

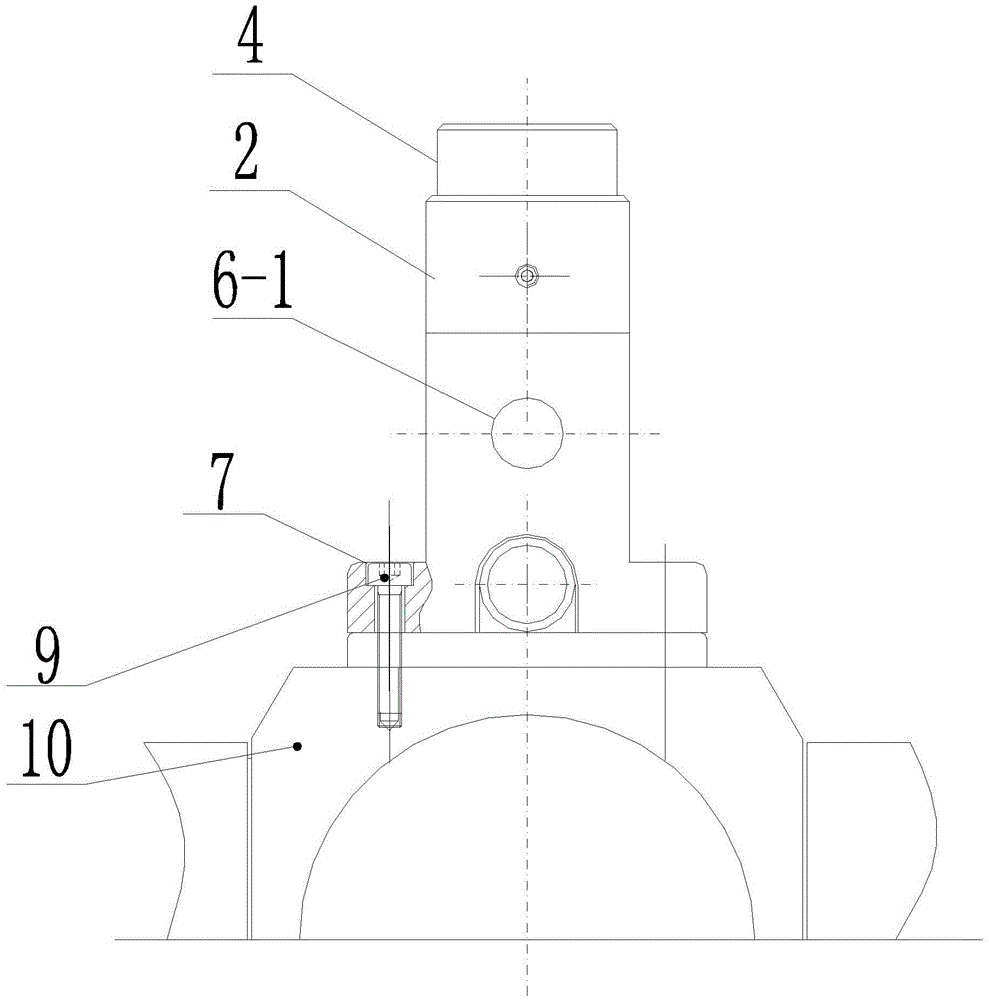

[0028] Specific implementation mode one: the following combination figure 1 and figure 2 Describe the present embodiment, the centering method of the laser centering device under the control point of the theodolite described in the present embodiment, it realizes based on the laser centering device under the control point of the theodolite, and the laser centering device includes a vertical micro-laser 1, Housing 2, laser protection glass 3, glass fixing cover 4, four laser adjustment screws 5, power supply device 6, two positioning through holes 7 and power supply device rear cover 8,

[0029] The shell 2 is divided into a first section and a last section, the first section is cylindrical, and the last section is provided with a cavity along the direction perpendicular to the axis of the first section, and the cavity is connected with the inner cavity of the first section, and the inner cavity of the first section is arranged vertically along the axial direction. Micro lase...

specific Embodiment approach 2

[0035] Specific implementation mode two: the following combination Figure 1 to Figure 3 Describe this implementation mode, this implementation mode will further explain the implementation mode 1, and the step 1 described in this implementation mode is specifically:

[0036] Select a fixed point 1 above the room, set up a theodolite below the fixed point 1, turn on the vertical micro-laser 1 after the telescope of the theodolite is horizontal, and accurately level and align the center of the laser beam spot with the fixed point 1;

[0037] Then turn the theodolite aiming part to observe whether the center of the laser beam spot deviates from the fixed point 1:

[0038] If not, the beam direction of the vertical microlaser 1 coincides with the vertical axis of the theodolite; then perform step 2;

[0039] If so, correct the position of the vertical microlaser 1:

[0040] After rotating the collimator of the theodolite for 180 degrees, determine the center of the laser beam sp...

specific Embodiment approach 3

[0041] Specific implementation mode three: this implementation mode further explains implementation mode two, step two described in this implementation mode is specifically:

[0042] Place the theodolite below the measurement control point; level the telescope of the theodolite, turn on the vertical micro-laser 1; move the legs of the theodolite or turn the foot screw to align the center of the laser beam spot with the measurement control point; extend the legs to adjust the circular level Bubbles; Finally, carry out precise leveling, and translate the theodolite aiming part to align the center of the laser beam spot with the measurement control point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com