Method for forecasting retained austenite change of Q&P steel after transformation under different temperatures

A technology of retained austenite and martensitic transformation, applied in the direction of testing metals, material inspection products, etc., can solve the problem that the law of austenite transformation cannot be accurately predicted, the law of austenite transformation cannot be represented, and it is difficult to apply to the automotive industry. and other problems, to achieve the effect of reducing time cost and economic cost, easy implementation and accurate implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

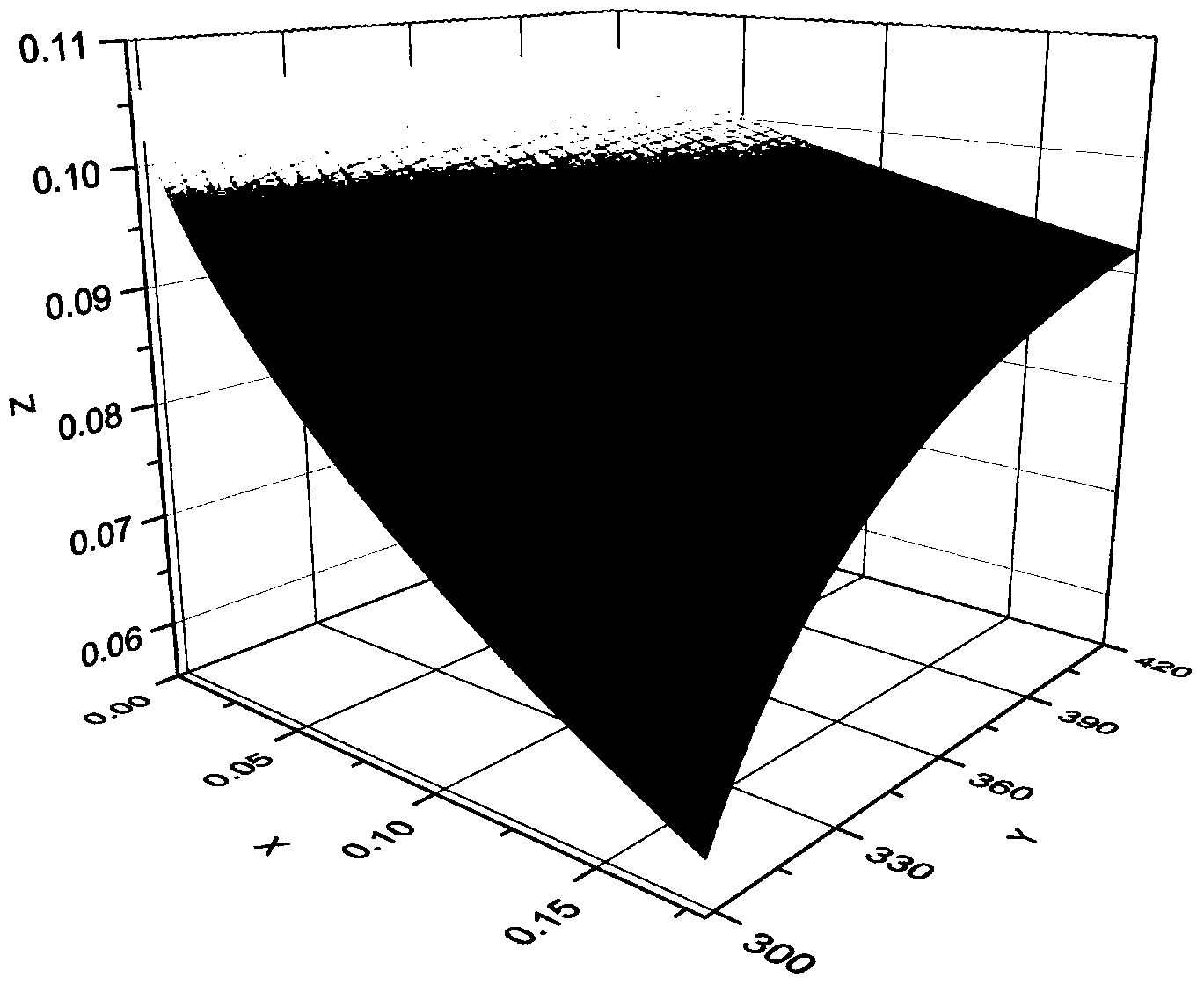

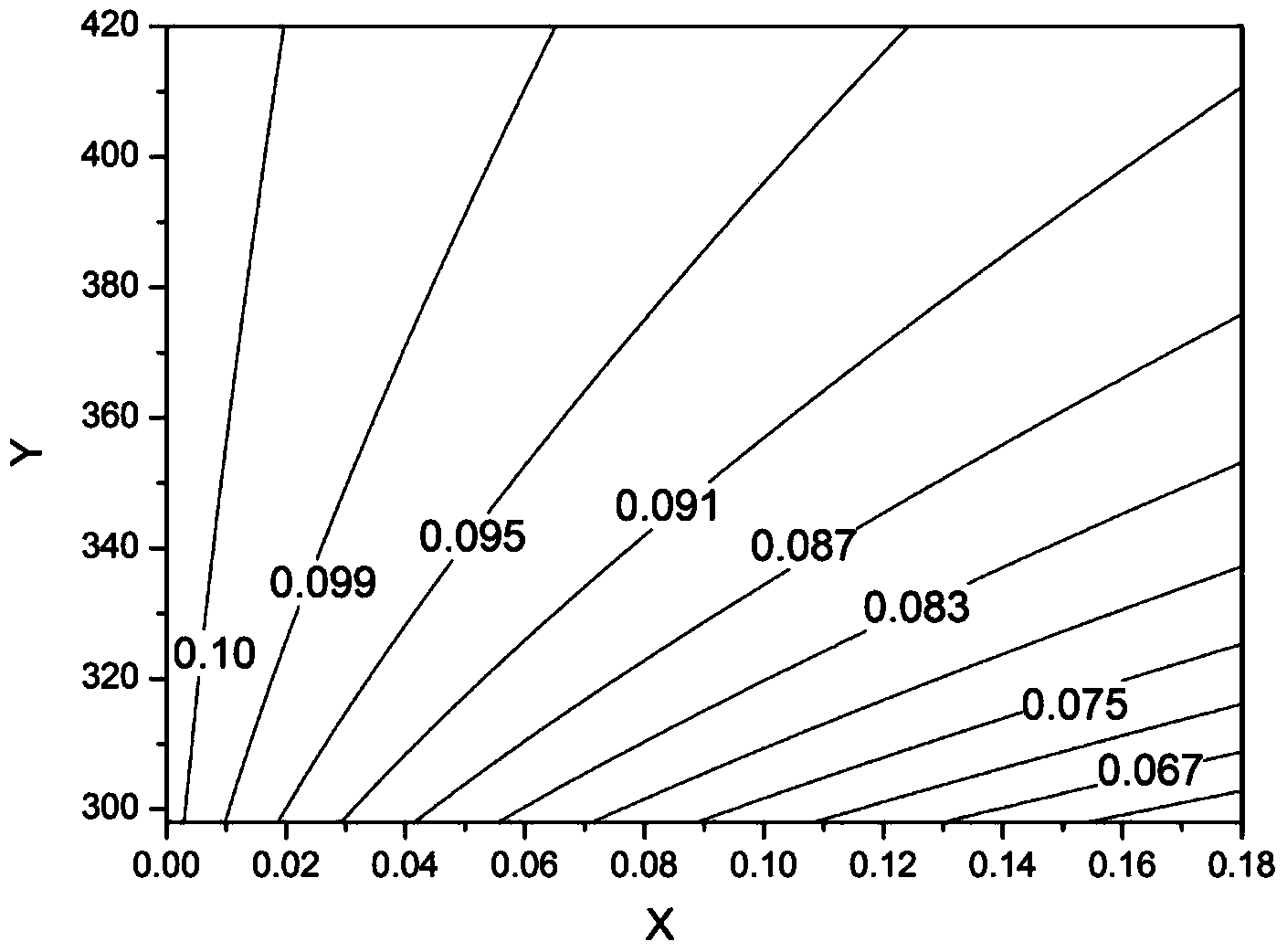

[0030] This embodiment relates to a method for predicting the change in volume fraction of retained austenite after deformation of Q&P steel at different temperatures, including the following steps:

[0031] (1) In this example, take the 1.2mm QP980 sheet as an example, prepare the single-drawn sample of Q&P steel sheet and the environment box, and measure the volume fraction of retained austenite before deformation by X-ray diffraction method as V A0 =10.61%;

[0032] (2) Then put the sample in the environmental chamber, and carry out the uniaxial tensile test at four ambient temperatures (298, 333, 373, 413K), unload after loading to a certain strain and measure the residual value of the central point of the sample Austenite volume content;

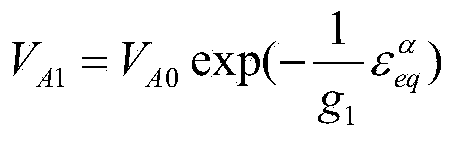

[0033] (3) The retained austenite content obtained in step (2) and the corresponding equivalent plastic strain data are used to establish an expression for the retained austenite content after uniaxial stretching at different ambient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com