Multifunctional transmission electronic cable

A multi-functional and electronic technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of waste of cables, increased cost and weight of cable materials, and failure of cables to conduct electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

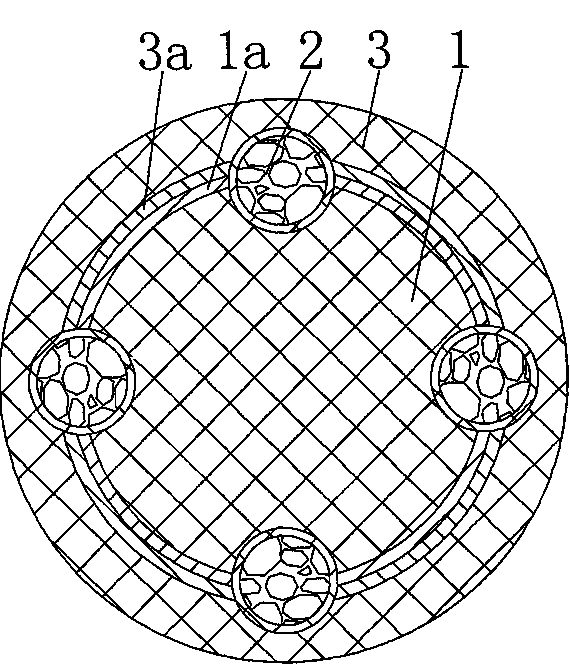

[0007] The multifunctional power transmission electronic cable of the present invention includes a non-conductive inner core 1, and the inner core 1 is a soft plastic filling strip or a rubber filling strip. A plurality of arc grooves are uniformly distributed on the outer peripheral surface of the inner core 1, and the arc of the arc grooves is 100 degrees. Two arc grooves are provided with signal shielding covers 1a. The signal shielding case is a metal shielding layer, and the signal shielding case is a shielding layer made of tin-copper. A cable inner core 2 is twisted on the outer surface of the inner core, and one cable inner core 2 is twisted in each arc groove. PVC isolation insulation 3 is extruded outside the inner core of the cable, and a plurality of arc-shaped grooves are uniformly distributed on the inner peripheral wall of the PVC isolation insulation 3. An outer shielding layer 3a is provided. The outer shielding layer is a metal shielding layer. The outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com