Method for processing anode device of ultraviolet photon counting integral imaging detector

An imaging detector and ultraviolet photon technology, which is applied in the manufacture of electrode assemblies, electrical components, cold cathodes, etc., can solve the problems of difficulty in achieving the accuracy of cross-position sensitive anodes, and inability to finely process upper conductive layers and insulating layers, etc. Achieve the effect of overcoming low machining accuracy, avoiding crosstalk between electrodes and reducing anode size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

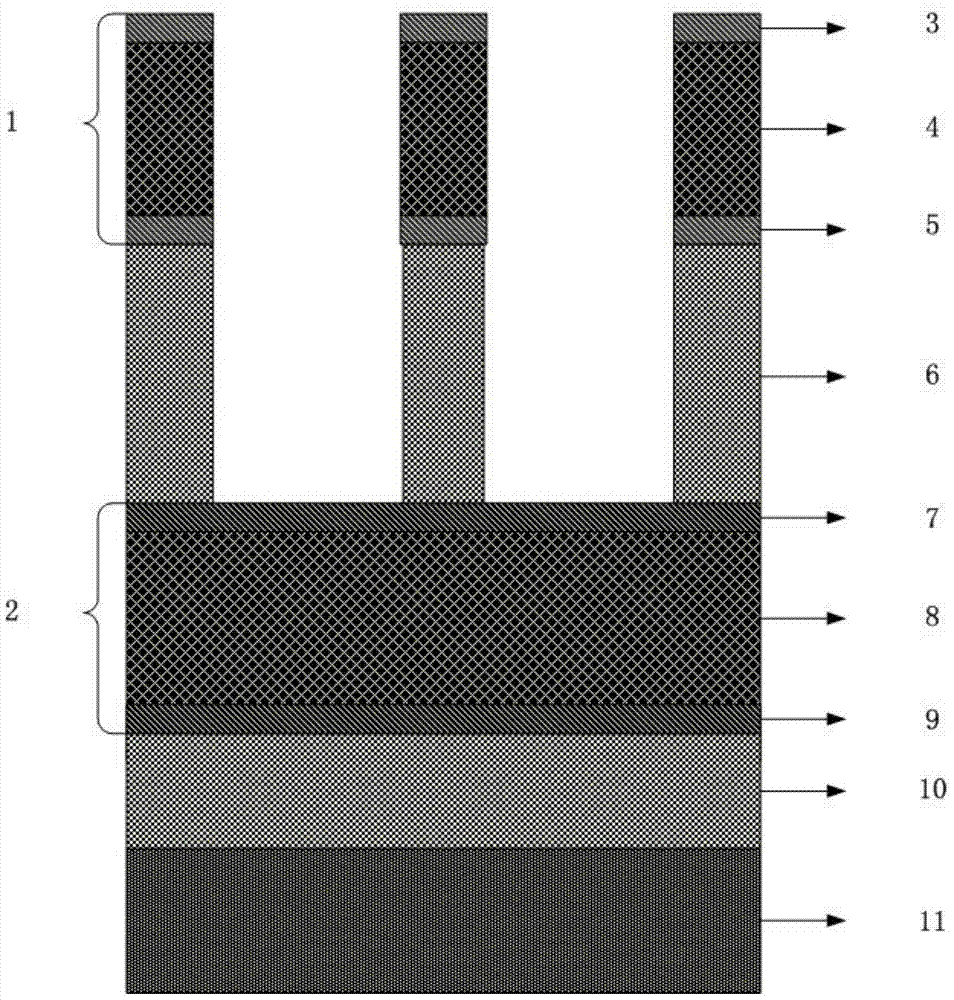

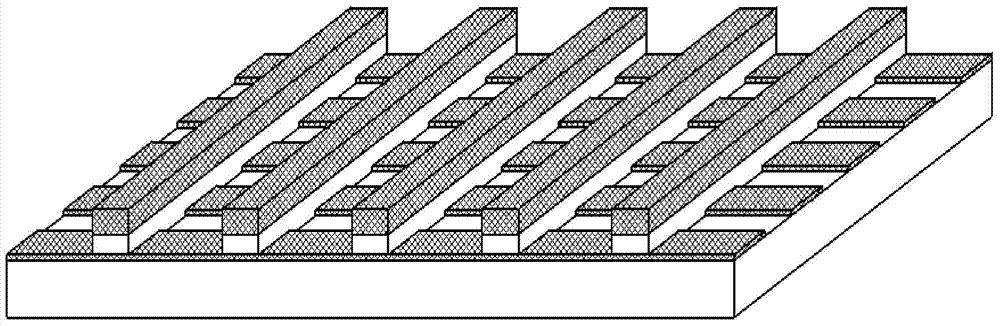

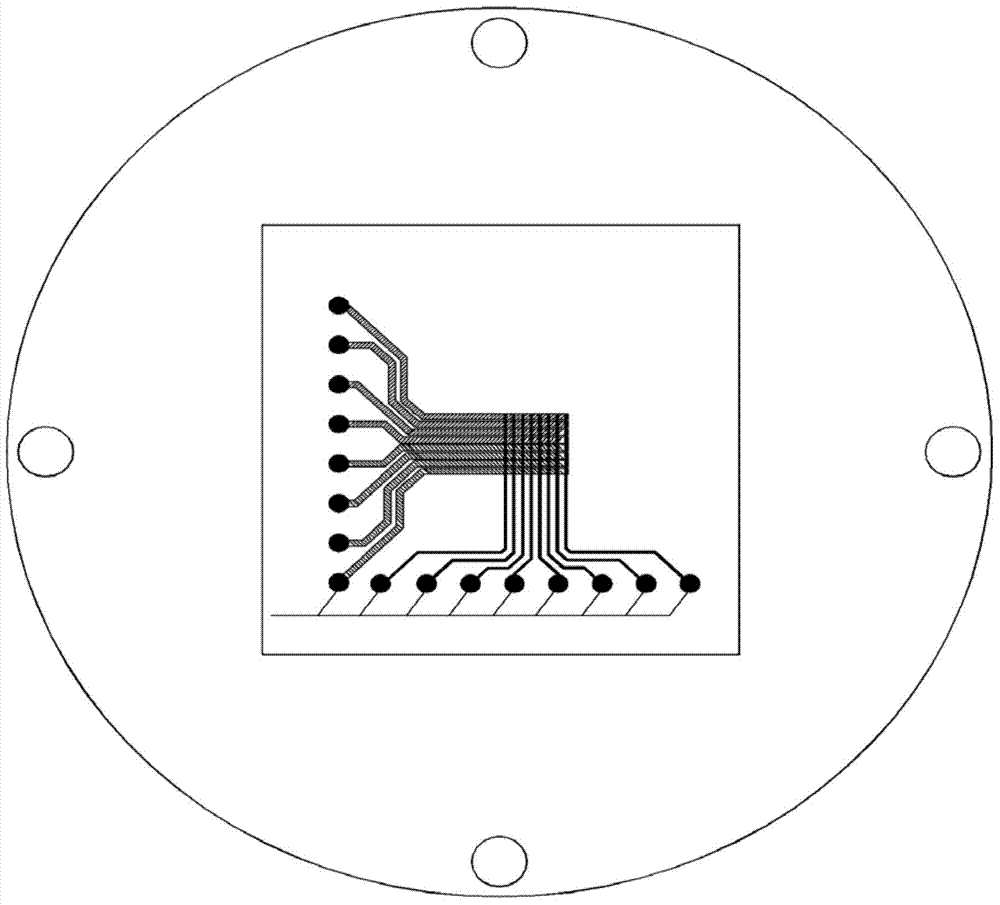

[0032] The present invention uses the widely commercialized PCB technology and relatively mature photolithography technology, combined with the unique design of the cross-position sensitive anode, processes the double-sided copper-clad PCB board, and processes the cross-position-sensitive anode that meets the precision requirements. . Such as figure 1 , figure 2 As shown, the specific process steps are as follows:

[0033] Step 1: Prefabrication of a photolithography mask. The parameters of the photolithography mask plate: the length is 100mm, the width is 100mm, and the period of the rectangular stripes is 0.5mm. The stripe width is 0.4mm, the stripe spacing is 0.1mm, and there is a rectangular groove between two adjacent rectangular stripes.

[0034] Step 2: Etching the anode pattern. Select two identical PCB boards, the characteristics of the PCB board: the upper and lower surfaces are covered by copper layer, the copper layer thickness is 4-10μm; the middle is a flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com