A device and method for realizing dynamic compensation of laser beam wavefront spherical aberration

A technology of laser beam and dynamic compensation, which is applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems of non-universality, expensive production, slowness, etc., and achieve the effect of benefiting industrial processing and power amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

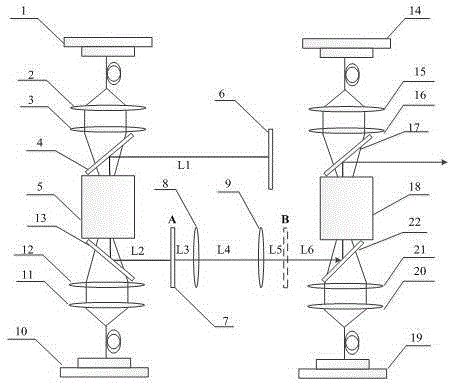

[0032] The first pumping source and the second pumping source are InGaAs semiconductor laser diodes with an output wavelength of 808nm. The first optical coupling system and the second optical coupling system are composed of two lenses with focal lengths of 20mm and 40mm. Described laser resonant cavity is made up of high reflection mirror, output mirror, the first dichroic mirror and the second dichroic mirror, and the reflectivity of high reflection mirror to laser is 99.9%, and the distance of high reflection mirror and the first laser gain medium is L1= 300mm, the reflectivity of the output mirror to the laser is 20%, the distance between the first laser gain medium and the output mirror is L2=120mm, the first dichroic mirror and the second dichromatic mirror are placed at 45° to the optical path, and the reflectivity of the resonant laser It is 99.9%, and the reflectance to the pump laser is 0.5%; the first laser gain medium is located in the resonator, and the first lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com