Solid-state oxide fuel cell

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problem of excessive temperature rise of the reformer, damage of the reformer, shortening of the service life of the reformer, etc. problem, to achieve the effect of suppressing temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

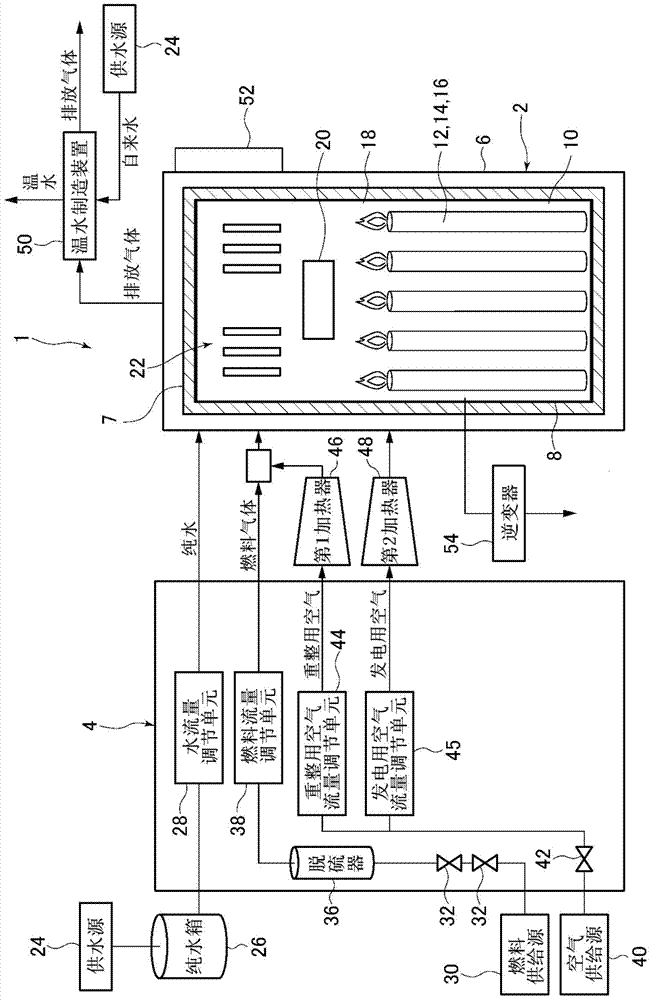

[0038] Next, a solid oxide fuel cell (SOFC) according to an embodiment of the present invention will be described with reference to the drawings.

[0039] figure 1 It is a diagram showing the overall configuration of a solid oxide fuel cell (SOFC) according to one embodiment of the present invention. as it should figure 1 As shown, a solid oxide fuel cell (SOFC) 1 according to one embodiment of the present invention includes a fuel cell module 2 and an auxiliary unit 4 .

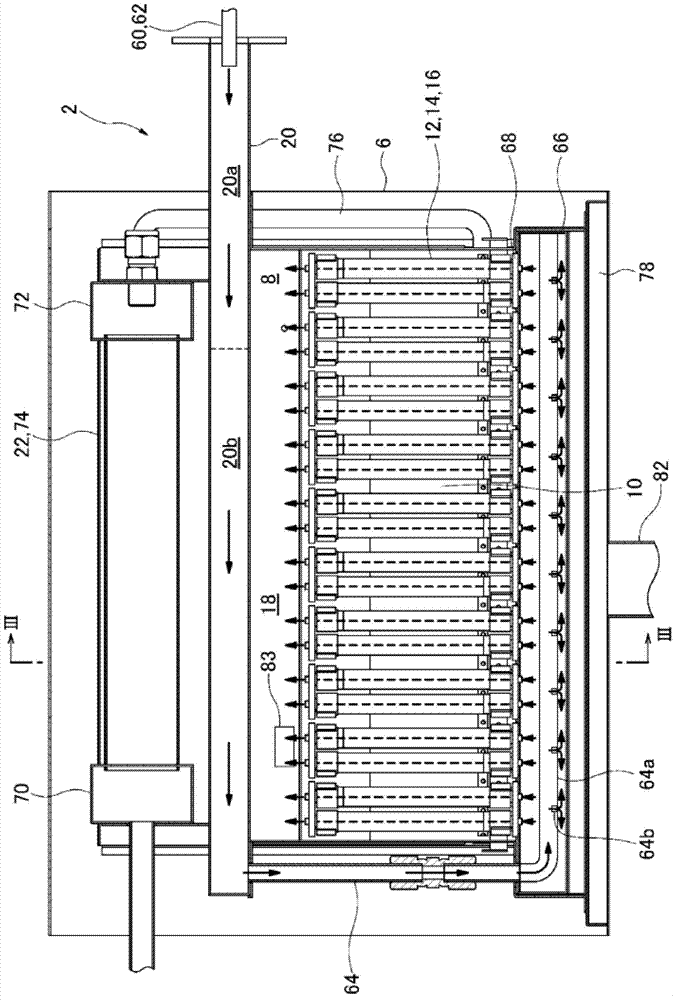

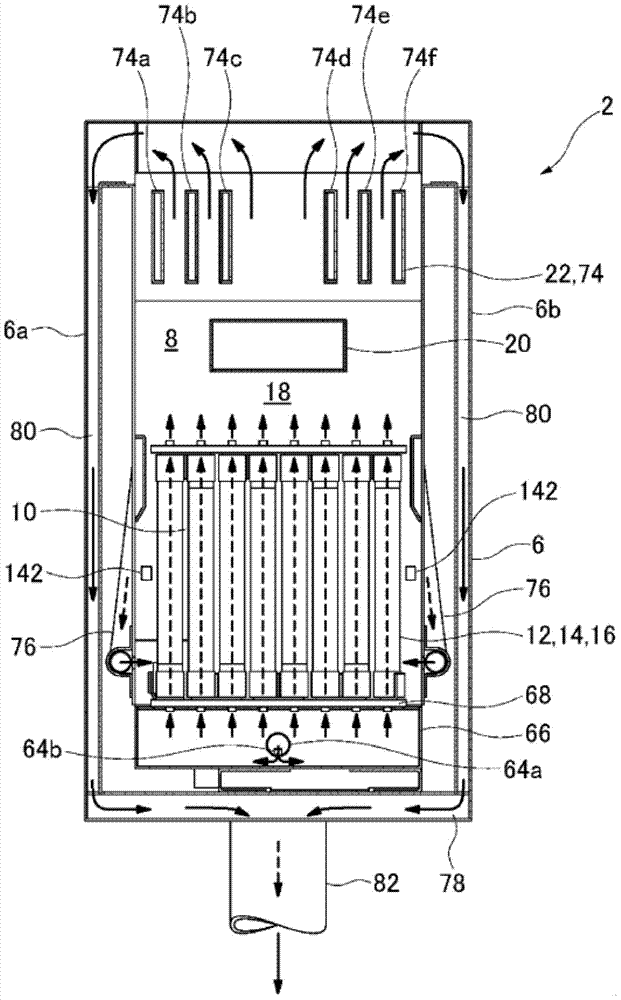

[0040] The fuel cell module 2 includes a case 6 , and a sealed space 8 is formed inside the case 6 via a heat insulating material 7 . A fuel cell assembly 12 that performs a power generation reaction using fuel and an oxidant (air) is disposed in a power generation chamber 10 that is a lower portion of the sealed space 8 . The fuel cell assembly 12 has ten fuel cell stacks 14 (refer to Figure 5 ), the fuel cell stack 14 is composed of 16 fuel cell single cell units 16 (refer to Figure 4 )constitute. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com