Whole vacuum negative pressure impregnation equipment and method for die casting type shell

A vacuum negative pressure and die casting technology, applied in the field of leaking parts, can solve the problems of clean separation, loss of product quality, loss, etc., and achieve the effect of less consumption, high production efficiency, and not easy to bump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

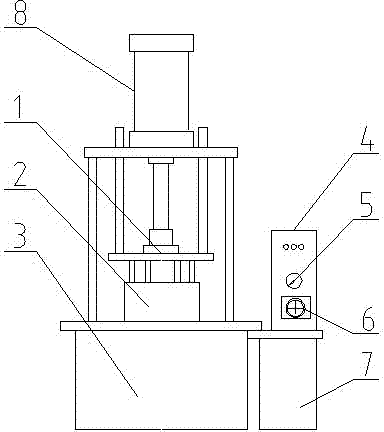

[0018] Such as figure 1 As shown, the overall vacuum negative pressure impregnation equipment of the present invention includes an air storage tank 7, a bracket, an impregnating agent box 3 arranged at the bottom of the bracket, an oil cylinder 8 with the top of the bracket and the piston end connected to the impregnating agent box 3, A sealing mechanism 1 located between the oil cylinder 8 and the impregnating agent tank 3, a control box 4 connected to the oil cylinder 8, and a vacuum gauge 5 and a vacuum pump 6 arranged on the control box 4; the sealing mechanism 1 can seal the shell of the die casting to be impregnated The cavity inside the body 2 is completely closed, and the vacuum pump 6 communicates with the sealing mechanism 1 through the air storage tank 7 .

[0019] The specific steps of the impregnation operation using the above-mentioned integral vacuum negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com