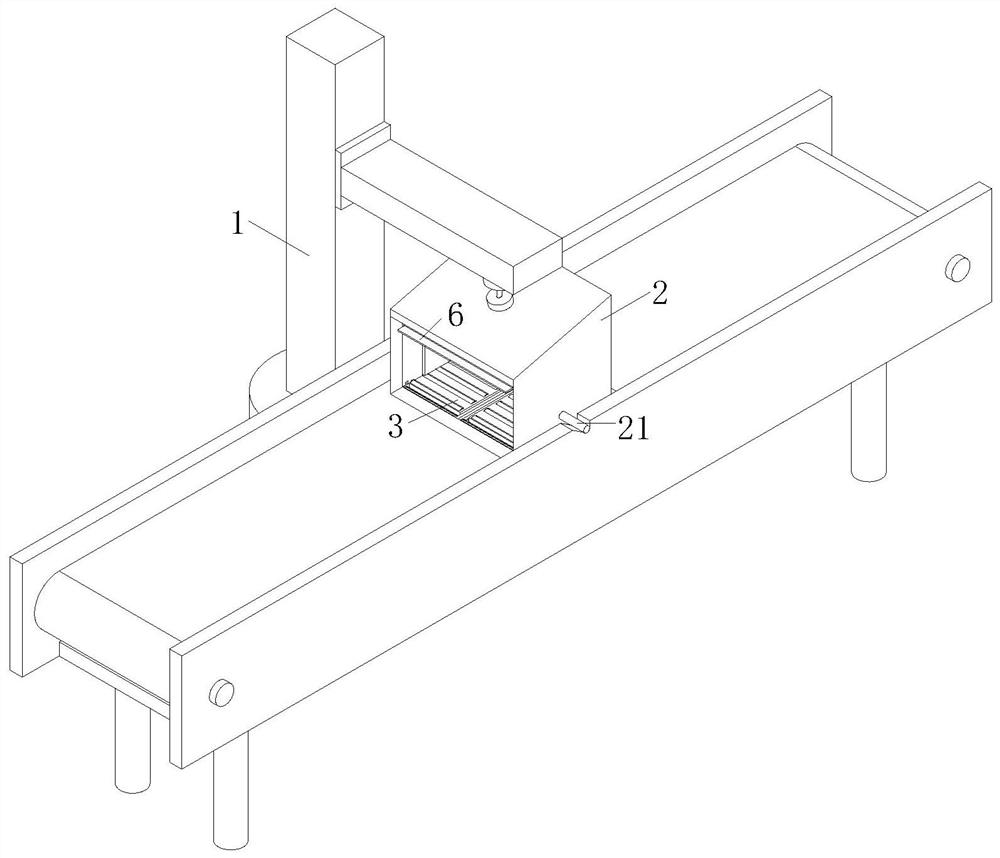

Automatic unloading stacker crane for logistics warehouse

An automatic unloading and palletizing machine technology, which is applied in the field of palletizing machines, can solve problems such as clamping too loose, easily damaged materials, and breaking the vacuum state, so as to avoid damage to materials, ensure palletizing efficiency, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

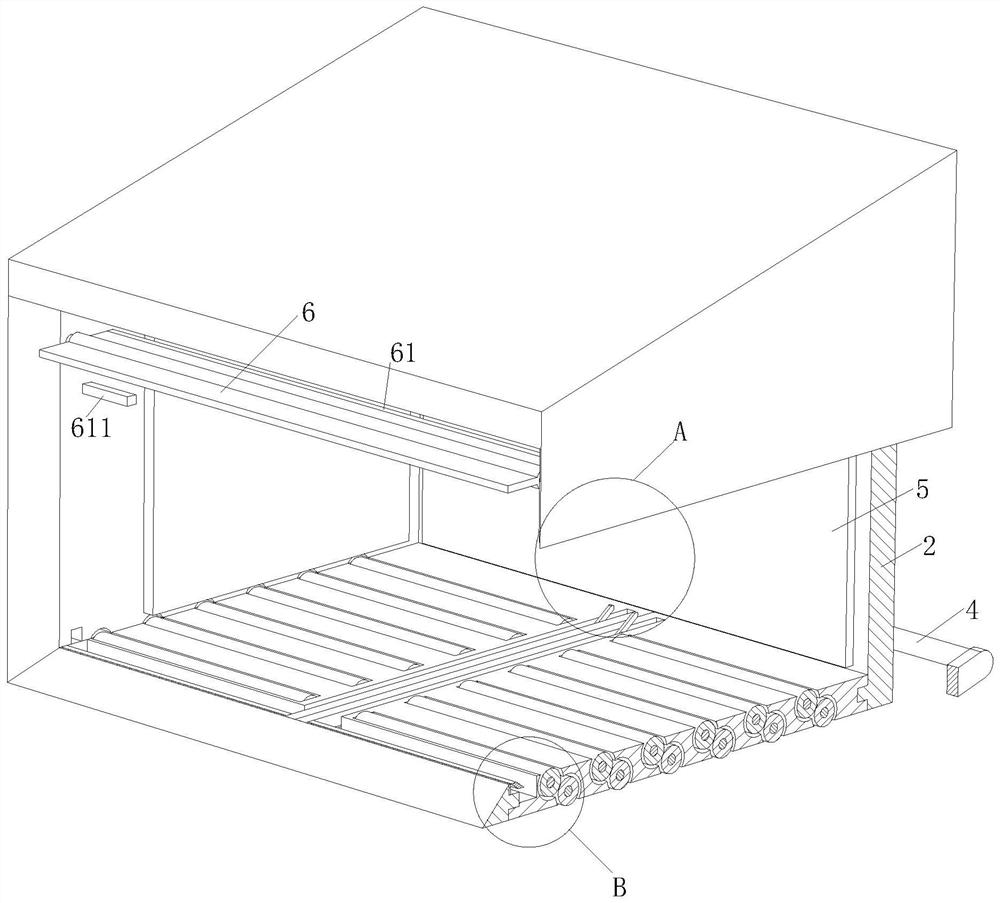

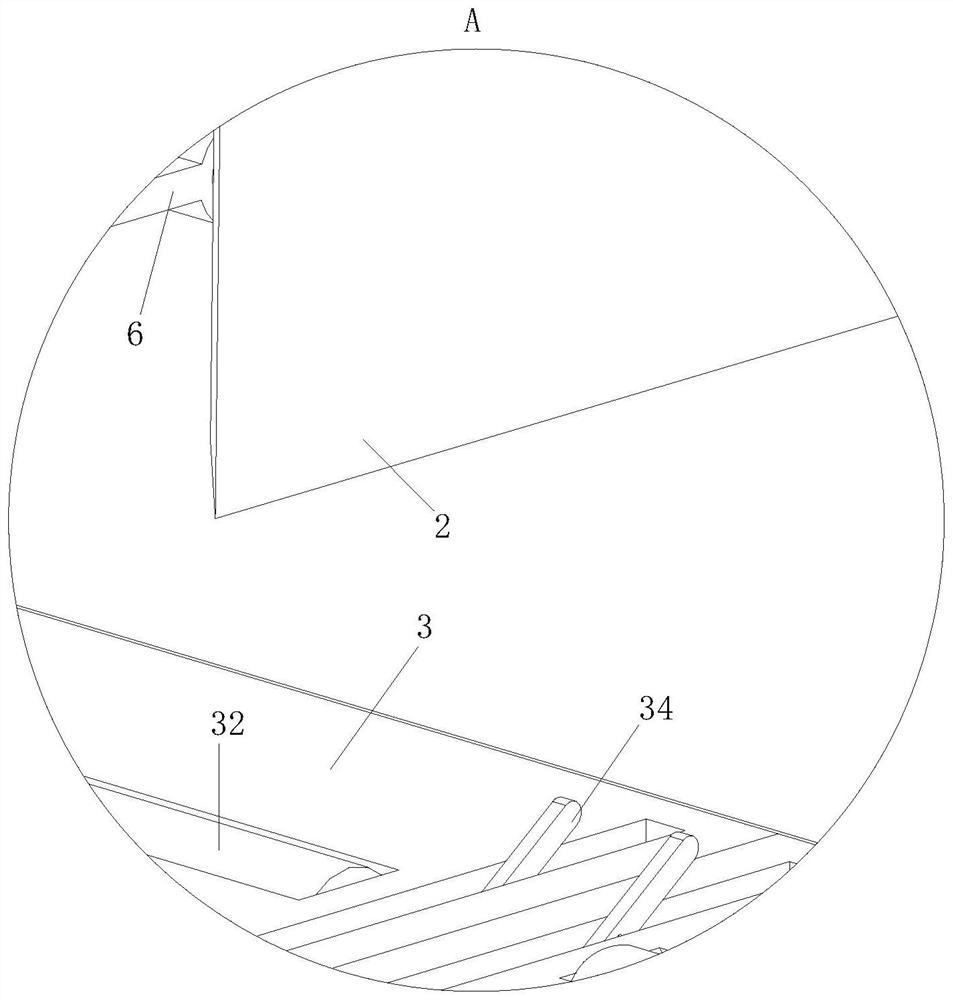

[0041]As an embodiment of the present invention, the bottom of the bottom plate 3 is rotatably connected with a first roller 31; during work, by setting the first roller 31, after the transport frame 2 is placed on the conveyor belt, the first roller The cylinder 31 is in contact with the conveyor belt, so that the friction between the transport frame 2 and the conveyor belt becomes rolling friction, reducing the friction between the two, reducing wear, ensuring the service life of the two, and installing on the bottom plate 3 The first roller 31 makes the bottom plate 3 inclined, and the bottom plate 3 is lower than the other end at the opening of the transport frame 2, so that the opening of the transport frame 2 is close to the conveyor belt, thereby facilitating loading of materials into the transport frame 2.

[0042] As an embodiment of the present invention, the top of the bottom plate 3 is rotatably connected with a second roller 32; during work, by setting the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com