Three-layer aluminum-plastic profile co-extrusion technology

A profile, aluminum-plastic technology, applied in the field of three-layer aluminum-plastic profile co-extrusion technology, can solve the problems of brittleness, insufficient surface hardness of aluminum-plastic composite profiles, poor heat insulation performance of aluminum profiles, etc., and achieve the effect of solving insufficient hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

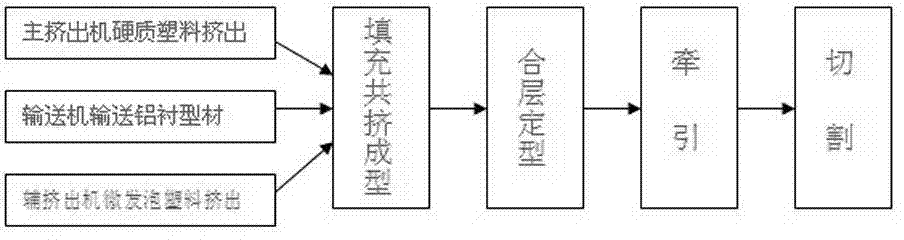

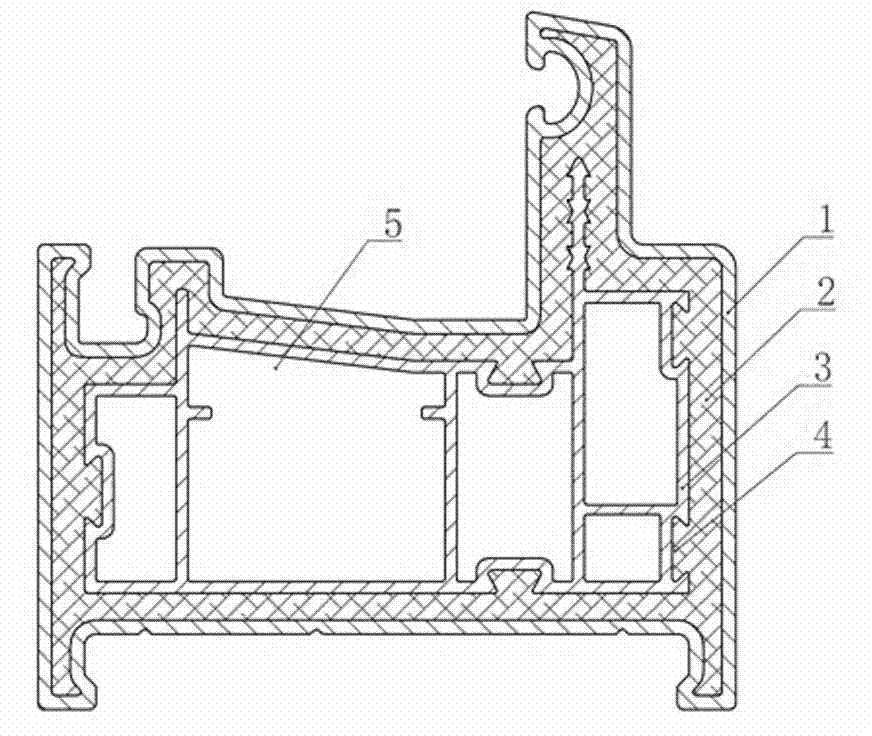

[0011] see figure 1 and figure 2 , the present invention is a three-layer aluminum-plastic profile co-extrusion process. The three-layer aluminum-plastic profile produced by this process is a new type of co-extrusion produced by a new composite extrusion molding technology on the basis of plastic profiles and aluminum alloy profiles. Extruded multi-layer profiles. In the extrusion molding process of this profile, combined with the extrusion molding technology of rigid plastic profiles and the co-extrusion molding technology of crust micro-foamed aluminum-plastic profiles, the extrusion molding of rigid plastics and the extrusion filling molding of micro-foamed plastics have been developed. Effectively combined with the new technology of extrusion molding of wrapped aluminum profiles, the molding process of buffer connection between rigid PVC plastic and metal aluminum profiles has been successfully completed.

[0012] see figure 2 The three-layer aluminum-plastic profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com