Liquid crystal display panel packaging structure

A liquid crystal panel and packaging structure technology, applied in the field of liquid crystal panel packaging structure, can solve the problems of broken COF, unable to set retaining wall structure, fragments, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

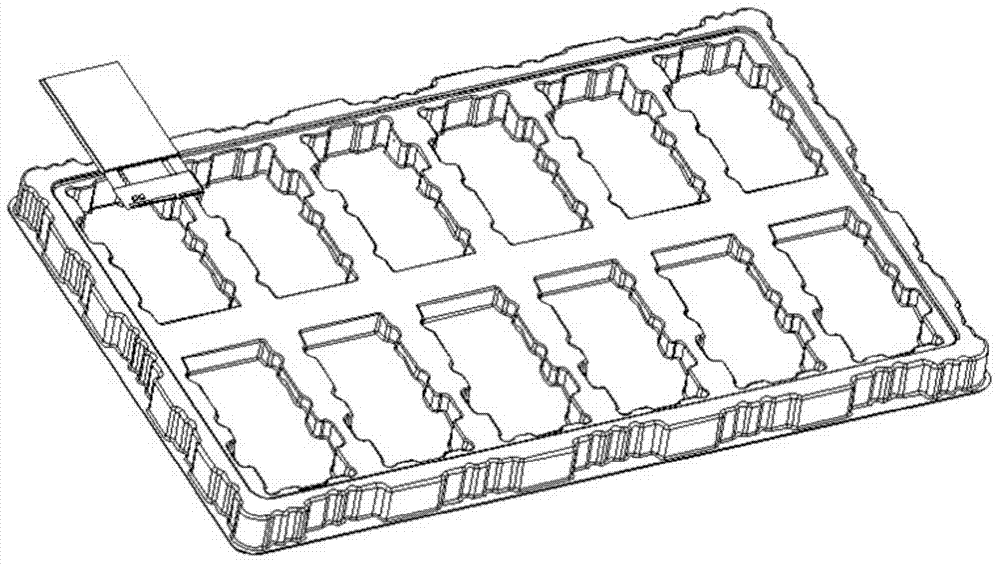

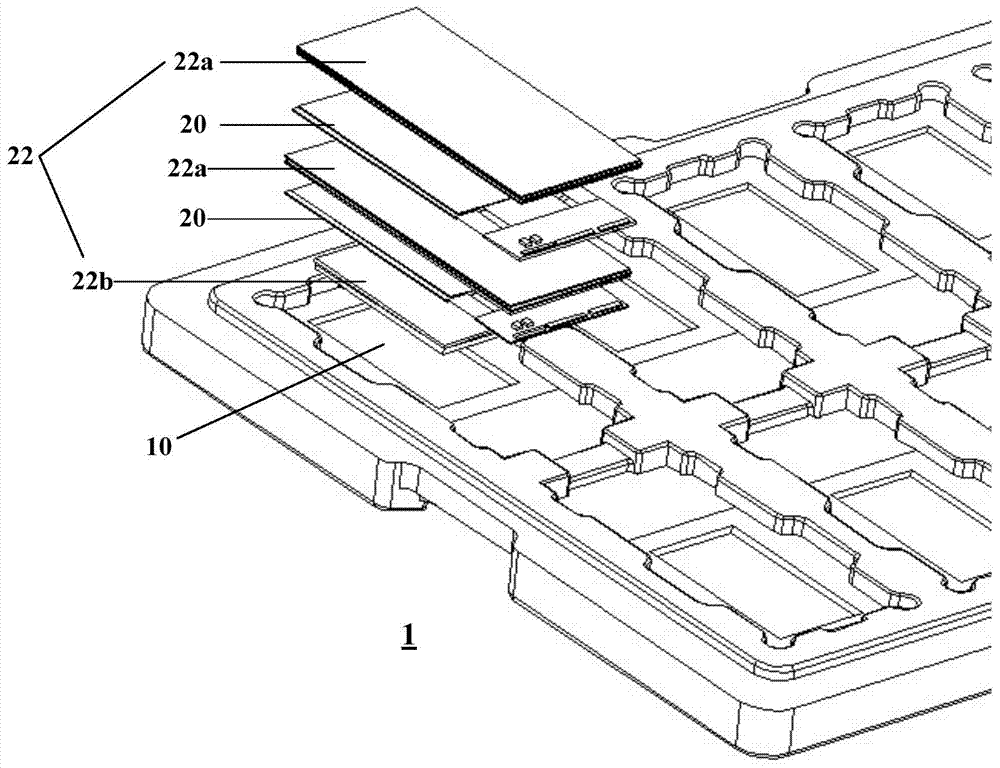

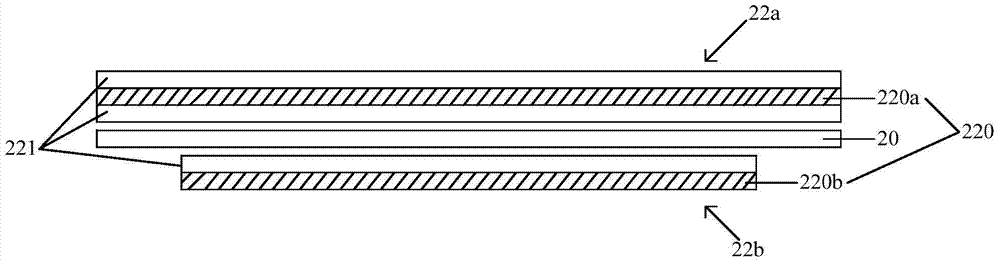

[0015] During the transportation of the liquid crystal panel, in order to protect the liquid crystal panel from shaking left and right to hit the packaging structure and cause damage to the liquid crystal panel, a packaging structure that can prevent the liquid crystal panel from shaking during transportation is provided. Reference figure 2 with image 3 As shown, a liquid crystal panel packaging structure of the present invention is used for packaging liquid crystal panels during transportation. The packaging structure 1 is provided with a plurality of storage slots 10, and the liquid crystal panels 20 are respectively stored in the packaging structure 1, wherein The packaging structure 1 further includes spacers 22 arranged on the upper and lower sides of the liquid crystal panel 20 and attracting each other to prevent the liquid crystal panel 20 from shaking and hitting the side surface of the receiving slot 10 during transportation.

[0016] Among them, refer to figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com