A device and method for monitoring the torsion of a tubular conveyor belt

A tubular conveyor belt and monitoring device technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of the overlapping position on both sides of the conveyor belt deviating from the top, inefficiency, accidents, etc. Easy to install and adjust, improve work efficiency, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

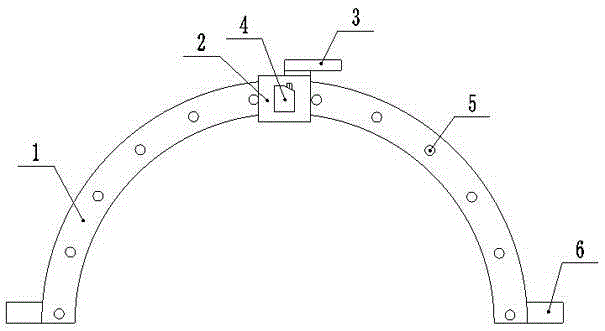

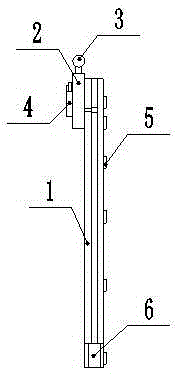

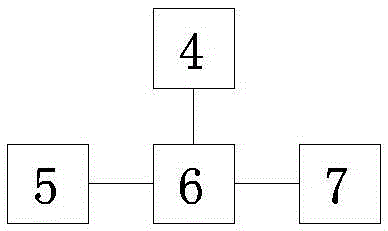

[0017] Such as figure 1 , figure 2 , image 3 As shown, a twist monitoring device for a tubular conveyor belt includes a guide rail 1, a slider 2, a motor 3, a displacement sensor 4, a proximity sensor 5, an acquisition circuit 6 and an alarm device 7. Specifically, the motor 3 is a micro motor , the displacement sensor 4 is a laser displacement sensor, and the acquisition circuit 6 is a high-speed AD acquisition circuit.

[0018] The guide rail 1 is bent into an arched shape along its length direction, specifically, the guide rail 1 is bent into an arc shape along its length direction, and the center of the arc is the section of the tubular conveyor belt when it is rolled into a tubular shape. The center of the circle can realize the accurate judgment of the sudden change in the distance between the surface of the tubular conveyor belt and the guide rail 1; Pass; described motor 3 and displacement sensor 4 are all installed on described slider 2, and motor 3 can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com