Steel lead laminated shear damper

A damper and lamination technology, applied in building components, anti-vibration and other directions, can solve the problem that the damper cannot use the shear force part well to dissipate energy, and achieve the reduction of seismic response, simple production and installation, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

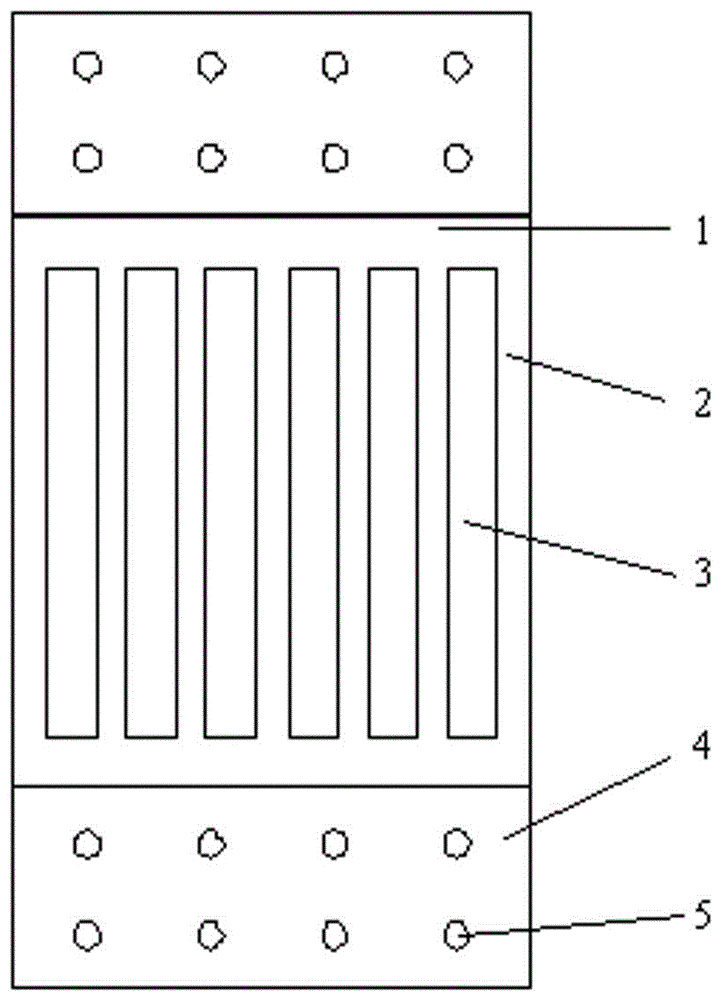

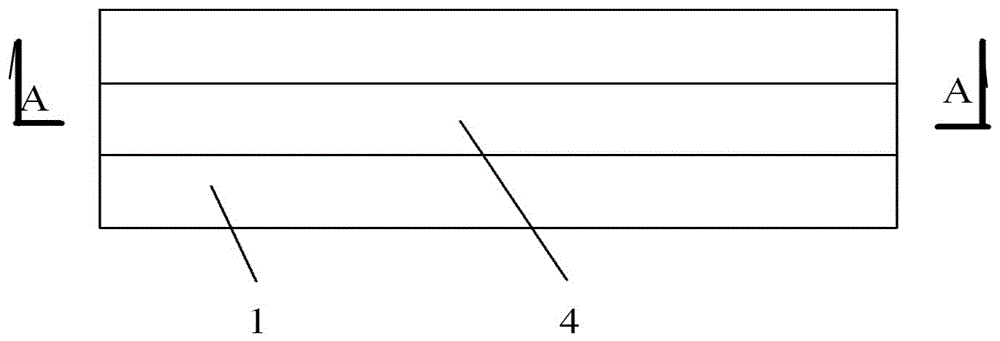

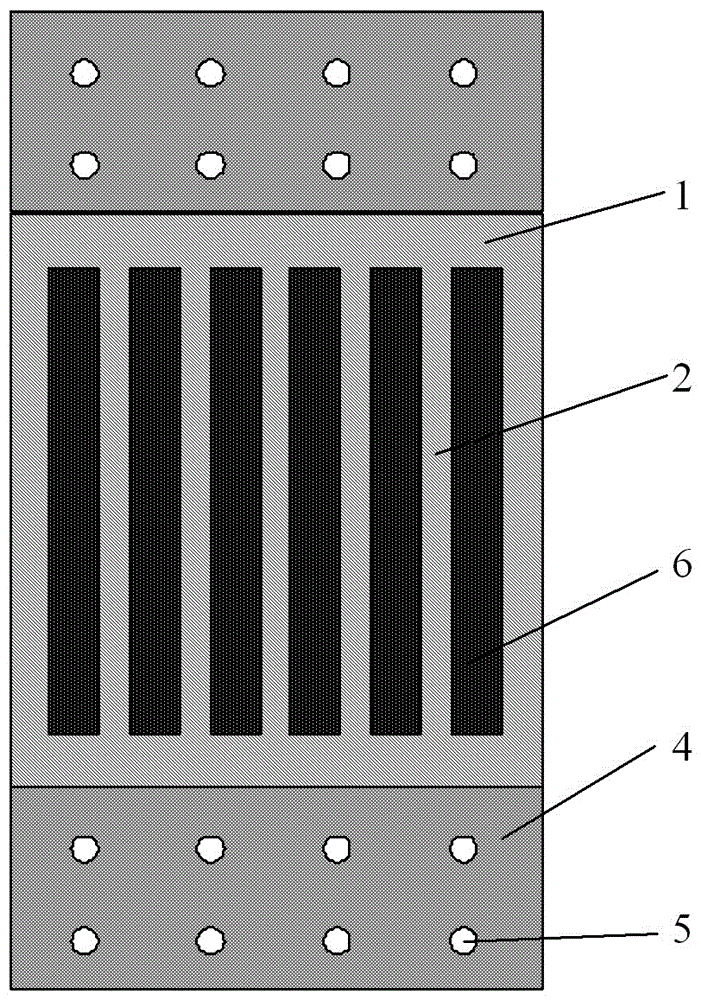

[0022] Such as figure 1 , 2 , The steel-lead laminated shear damper shown in 3, 4, and 5, 1 is the steel end plate of the damper; 2 is the energy-dissipating soft steel plate; 3 is the energy-dissipating lead plate blocking plate; 4 is the damper fixing plate; 5 is a bolt hole; 6 is an energy-dissipating lead plate; 7 is an energy-dissipating part; 8 is a bolt; 9 is a nut; 10 is an angle steel; 11 is an I-beam; 12 is a channel steel; The energy-dissipating mild steel plate 2 and the energy-dissipating lead plate 6 are stacked to form the energy-dissipating part 7; The damper steel end plate 1 is welded with the damper fixing plate 4, one end of the damper fixing plate 4 is connected with the I-beam 11 by bolts 8 and nuts 9 through the angle steel 10 and the channel steel 12, the other end of the damper fixing plate 4 The angle steel 10 and the channel steel 12 are connected with the herringbone support top 13 by bolts 8 and nuts 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com