Utilization method of low-pressure industrial exhaust gas

An industrial exhaust, low-pressure technology, applied in pressure pumps, machines/engines, non-displacement pumps, etc., can solve problems such as power consumption, and achieve the effects of improving efficiency, reducing costs, and operating flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

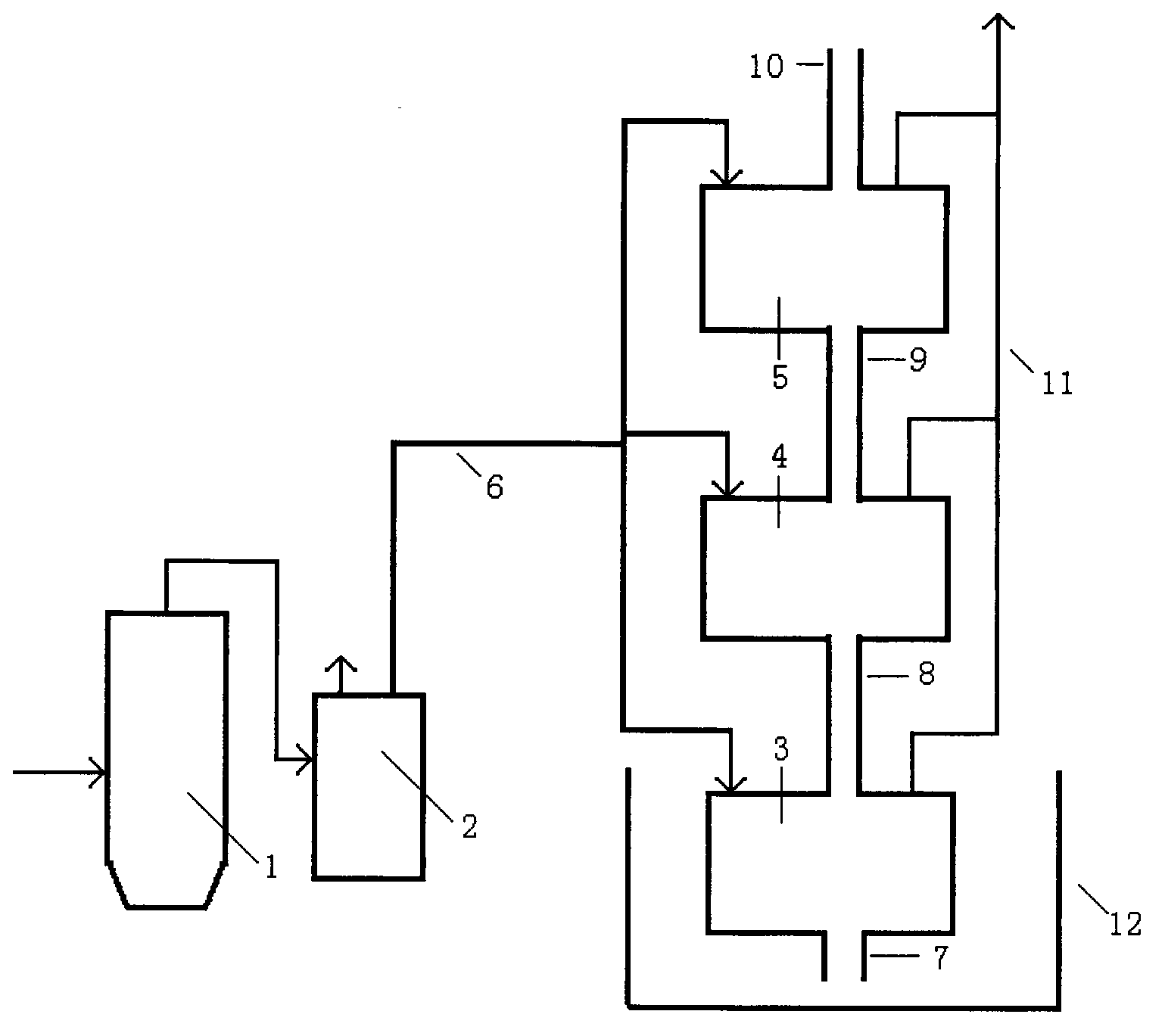

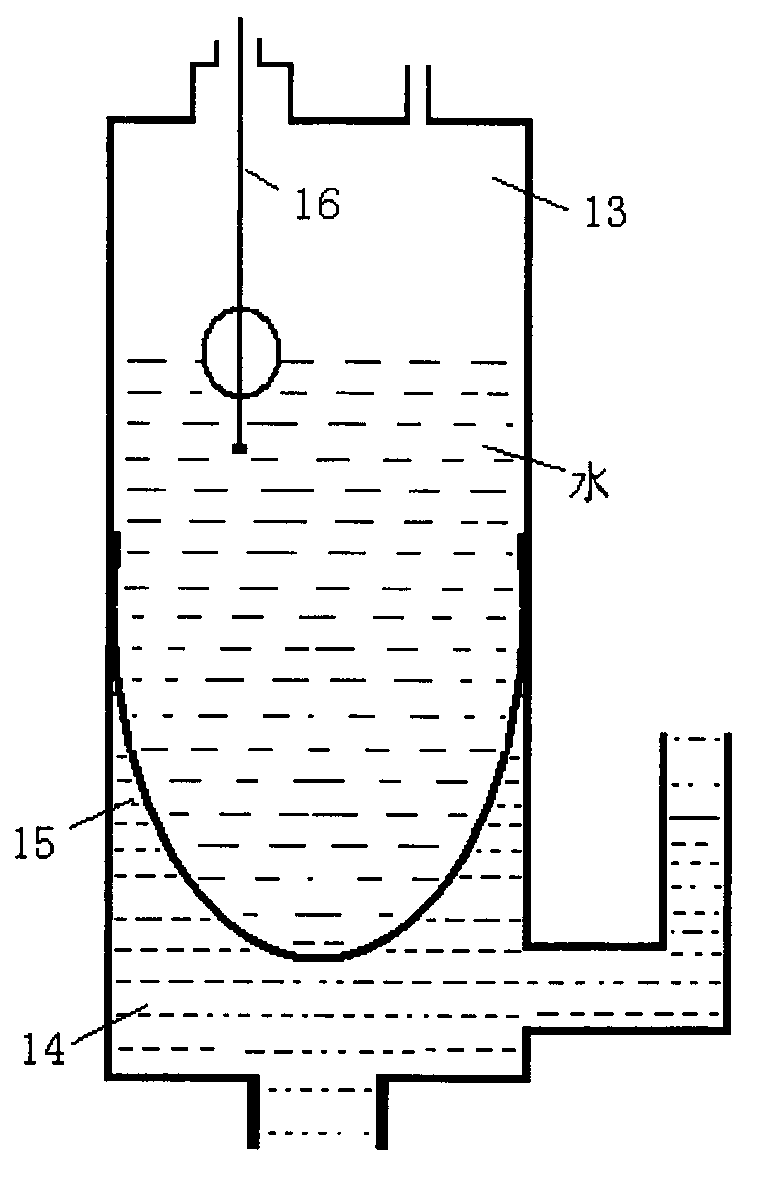

[0021] attached figure 1 A specific embodiment is a multi-stage air pressurized water machine driven by low-pressure industrial tail gas. The low-pressure industrial exhaust gas enters the exhaust gas purification device 1 through the pipeline to remove solid or liquid substances, and then enters the voltage stabilizing device 2 through the pipeline. The low-pressure exhaust gas discharged from the voltage stabilizing device 2 enters through the pipeline 6 and drives the first-stage air pressure water press 3 and the second-stage respectively. Air pressure water press 4, three-stage air pressure water press 5, the water in the pool 12 enters the first-level air pressure water press 3 through the water inlet pipe 7, and then continuously enters the second-level air pressure water press 4 through the upper water pipe 8 under air pressure , and enter the three-stage air pressure water press 5 through the upper water pipe 9 under the air pressure, and finally discharge through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com