Automobile ball seat structure

A ball seat and automobile technology, applied in the direction of pivot connection, etc., can solve the problems of arc-shaped bottom of ball seat, low stability, low oil storage, strong demoulding deformation, etc., to achieve excellent lubrication and improve softness and stability. , the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

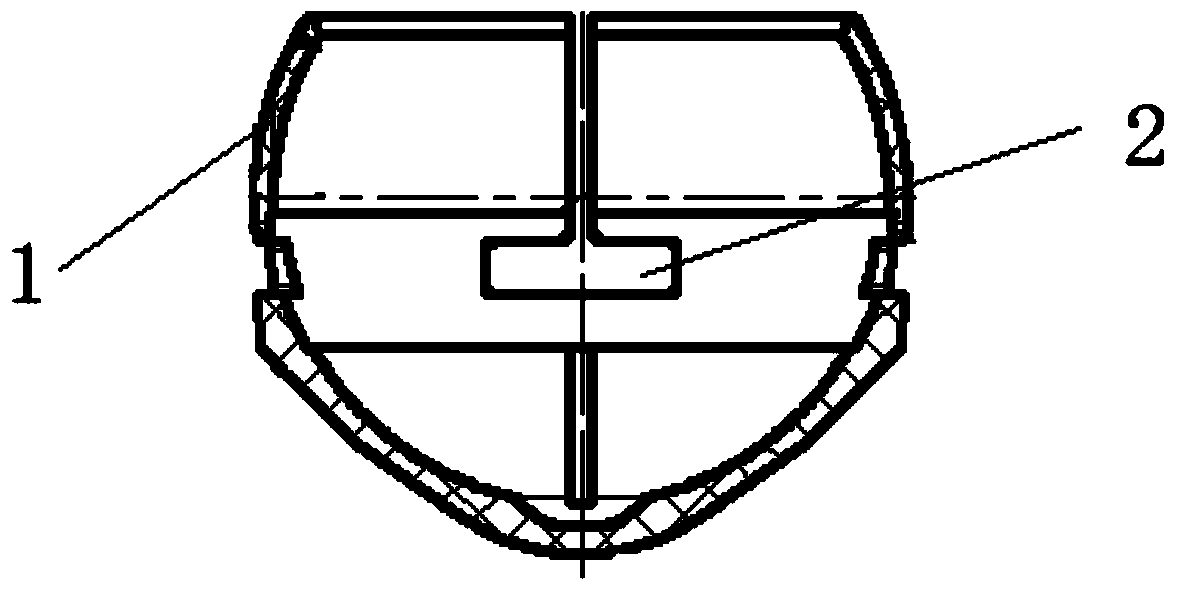

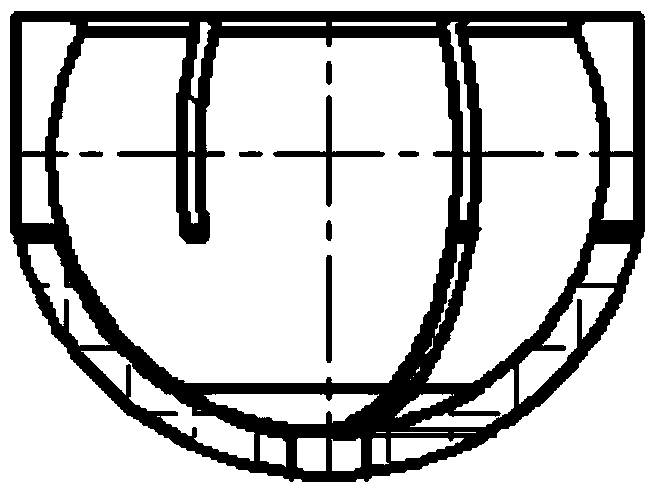

[0012] like figure 1 An automobile ball seat structure is shown, including a ball seat body 1, a "T"-shaped oil groove 2 is arranged on the inner wall of the ball seat body 1, and the inner wall of the ball seat body 1 is in the shape of a spherical arc. The curvature of the outer wall of the ball seat body 1 from the middle to the bottom is smaller than the curvature of the inner wall of the ball seat body from the middle to the bottom.

[0013] Compared with the ball seat of the original structure, this ball seat has added a "T" groove structure. The addition of the "T" groove increases the storage capacity of lubricating oil, which plays an excellent role in lubrication and reduces friction; the ball seat adopts a one-time Forming and integral demoulding technology make the deformation of the inner spherical surface of the ball seat after demoulding and molding extremely small, increase the contact surface between the ball pin and the ball seat, and improve the softness an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com