Electric automatic gear shifting tricycle or quadricycle rear-drive shifter

A technology for automatic shifting and tricycles, which is applied to the control of instruments, transmission boxes, transmission devices, etc., can solve the problems of complex structure and inconvenient manufacturing and assembly of rear drive shifters, and achieve the effect of simple structure and convenient manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to specific embodiments and accompanying drawings.

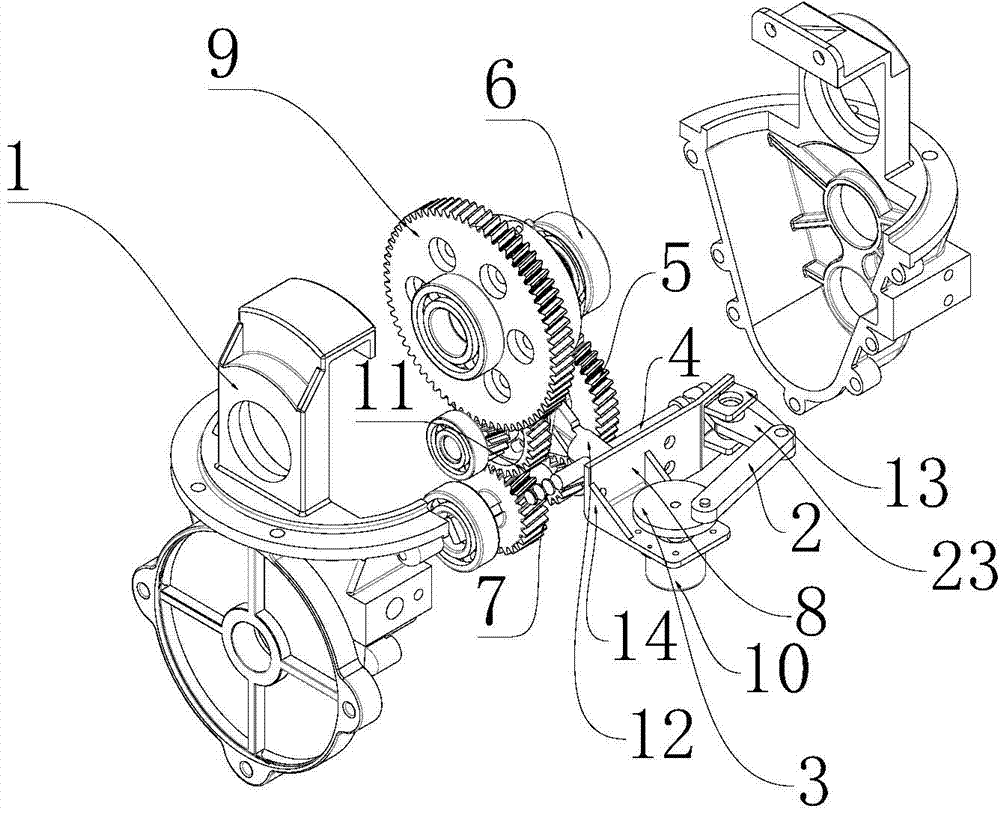

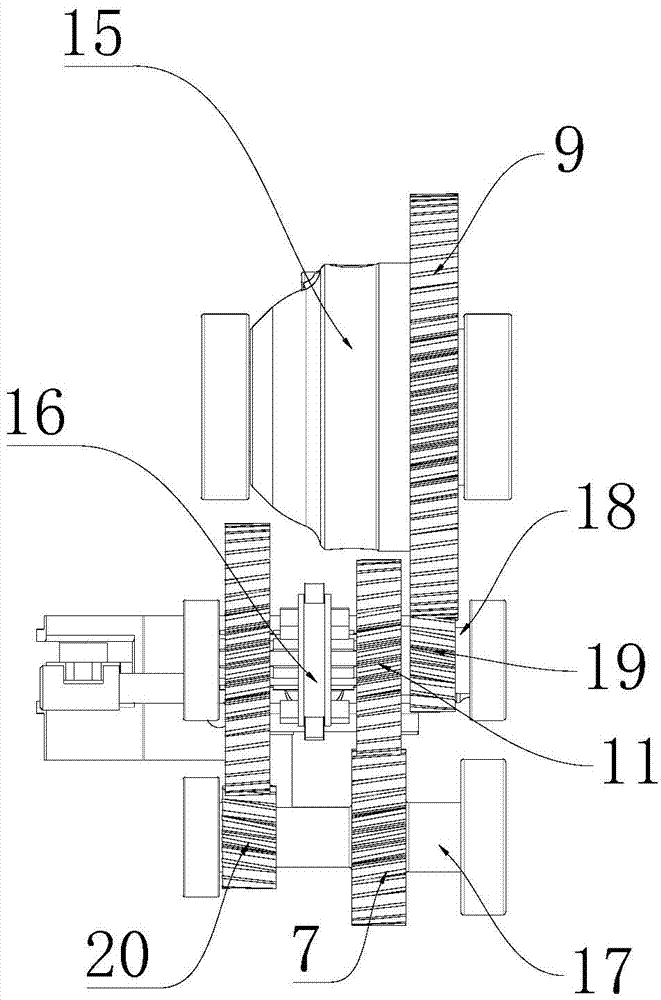

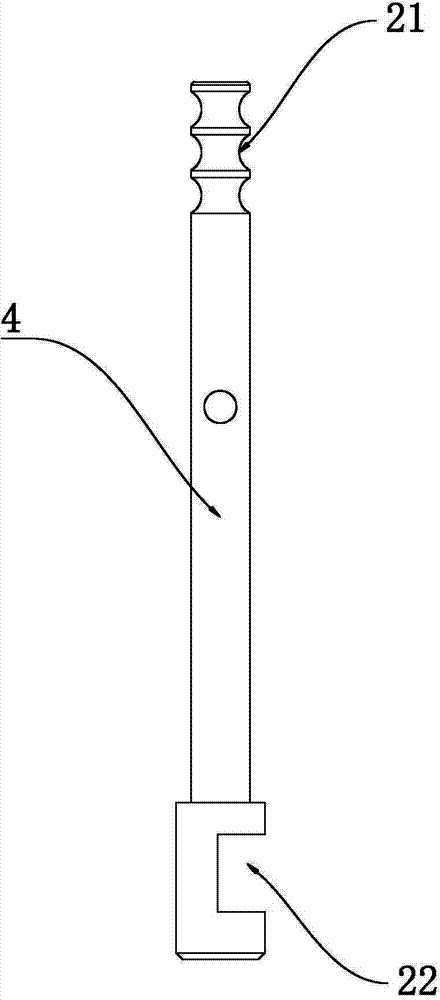

[0019] like Figure 1-3 The illustrated rear-drive shifter for a tricycle or four-wheel vehicle with electric automatic shifting includes a box body 1, a driving shaft 17, a driven shaft 18 and an inner swivel 15 arranged in the box body 1, so The driving shaft 17 is fixedly provided with a shaft fast tooth 7 and a shaft slow tooth 20, the driven shaft 18 is fixedly provided with a first transmission tooth 19, and is hollowed with a shaft fast tooth 7 and a shaft respectively. The first shift tooth 11 and the second shift tooth 5 meshed with the slow tooth 20, the first transmission tooth 19 meshes with the driving tooth 9 provided on the inner rotating body 15, the driving shaft 17, the driven shaft 18 Bearings 6 are connected to both ends of the inner rotating body 15 , and a combination ring 16 is also fixedly connected between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com