Measuring tool for roundness of glass circular disk and measuring method thereof

A measuring tool, roundness technology, applied in mechanical counter/curvature measurement, etc., can solve the problems of long time required, affecting the roundness measurement results of glass discs, and difficulty in inspection, and achieve the effect of simple measurement method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

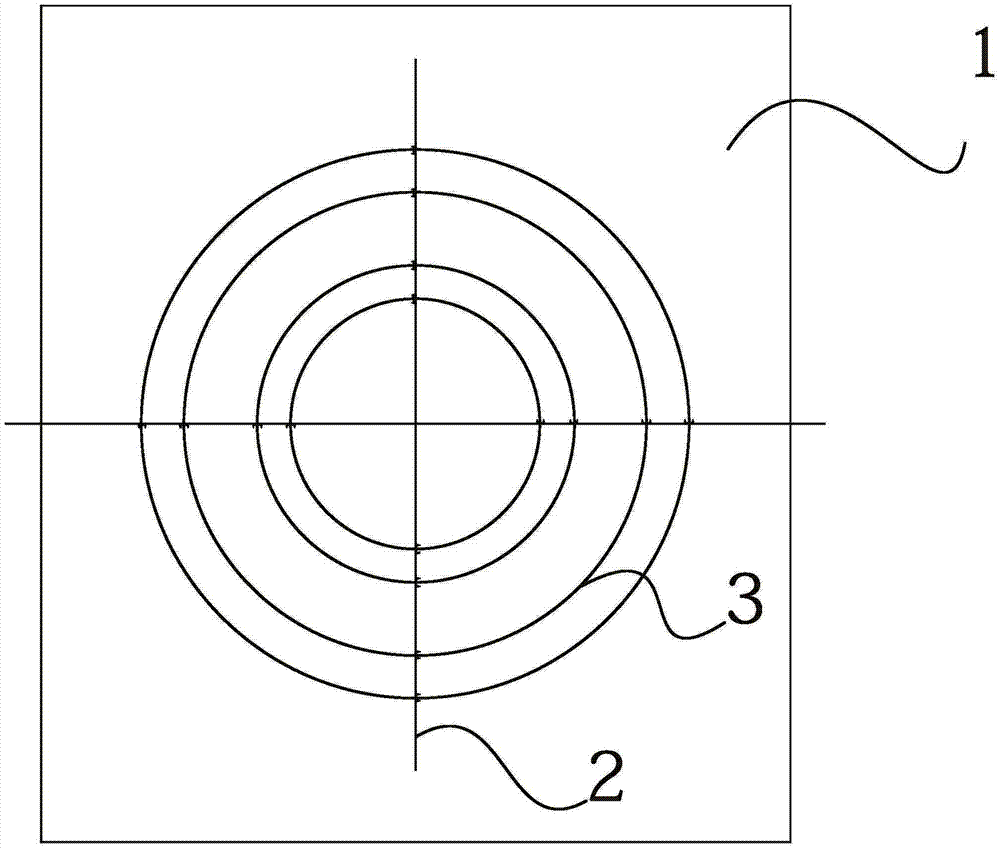

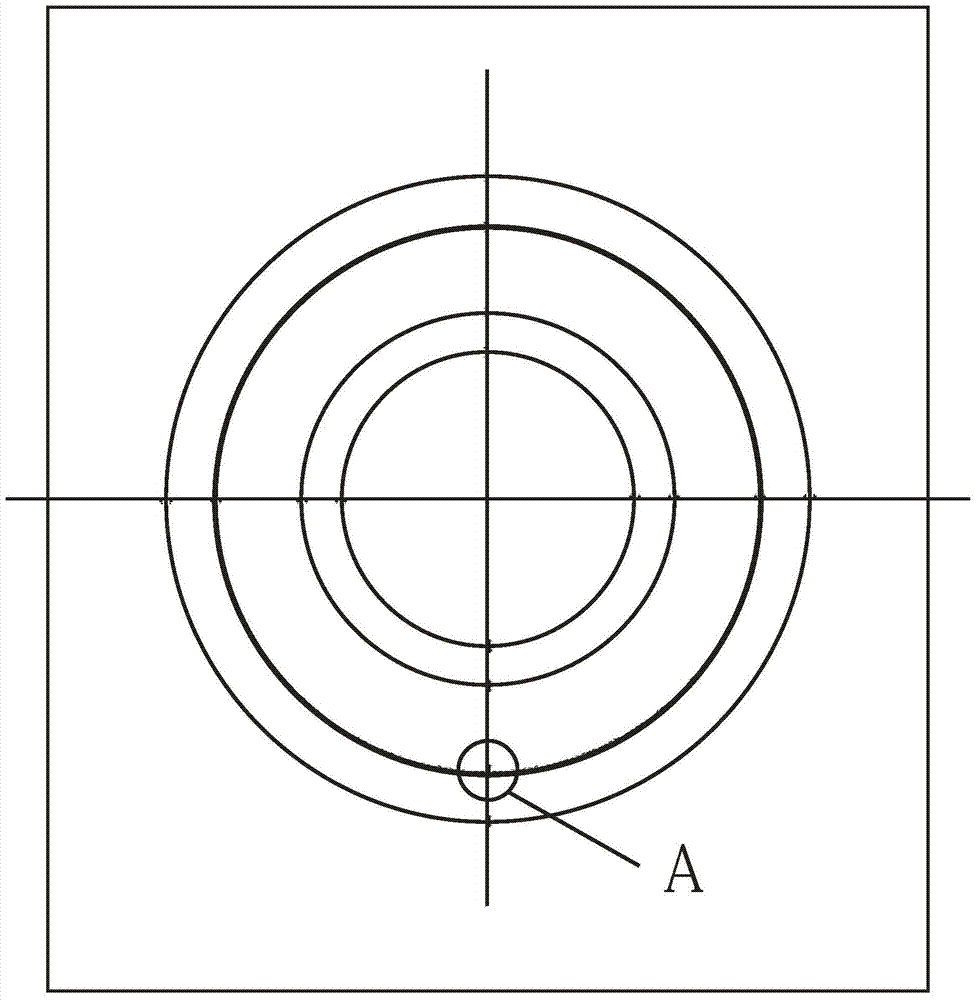

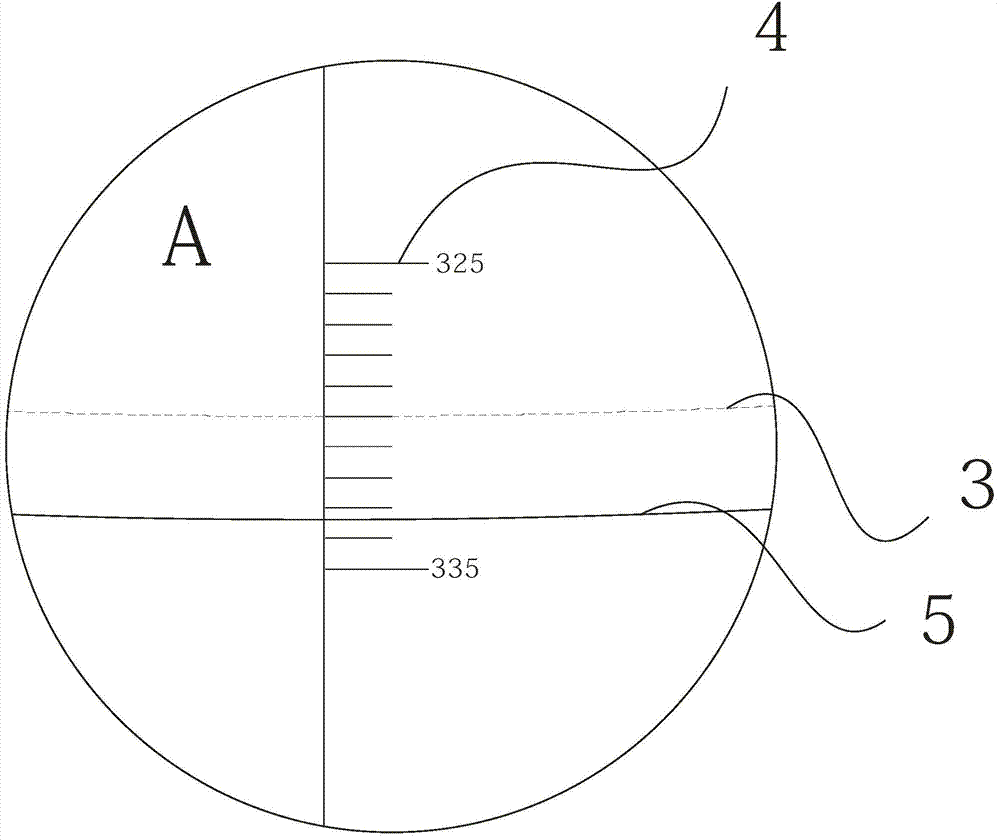

[0022] like figure 1 Shown is a measuring tool for the true roundness of a glass disc, including a standard part 1, the surface of the standard part 1 is printed with cross lines 2, and a plurality of concentric circles 3 are printed with the midpoint of the cross line 2 as the center The crosshair 1 includes four line segments starting from the midpoint, at least one line segment is marked with a scale 4, and the zero point of the scale 4 is the midpoint of the crosshair 2.

[0023] Preferably, the standard part 1 has a square or circular structure.

[0024] Preferably, as shown in the figure, the number of the concentric circles 3 is four, and their radii are respectively 210mm, 250mm, 330mm and 375mm. In addition, the standard part 1 can be made into concentric circles with different radii according to different specifications of the glass disc 5 to be measured.

[0025] Preferably, in order to make the measurement result more accurate, the printing width of the concentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com